Dry Hcl Gas Generator Plant

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Column Height | 10M |

| Column Diameter | 1M |

| Steam Pressure | 10 Bar |

| Acid Feed Rate | 100L/Hr |

| Gas Flow Rate | 100M³/Hr |

| Drying Agent | Calcium Chloride |

| Features | Dry Hcl Gas, Continuous Process, High Purity, Efficient Design, Cost Effective, Easy Operation, Safe Process |

Product Overview

Key Features

Clients can avail from us a wide range of Dry HCL Gas Generator Plant, as we are engaged in manufacturing, supplying and exporting in Vapi, Gujarat, India.

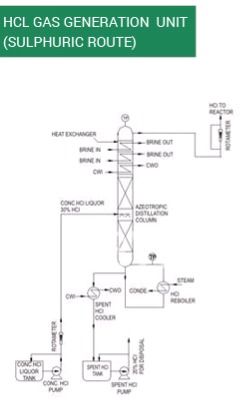

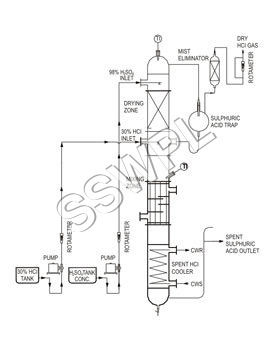

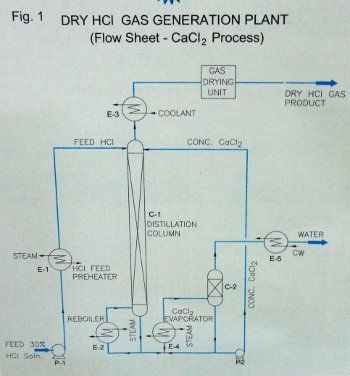

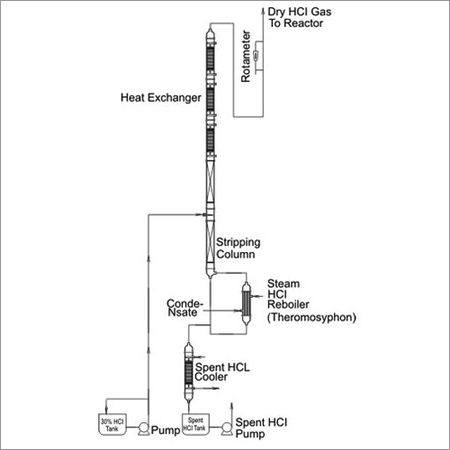

>> The plant has been designed as a continuous process to produce dry HCl gas by the process of distillation of 30% hydrochloric acid solution along with a co-current stream of calcium chloride solution.

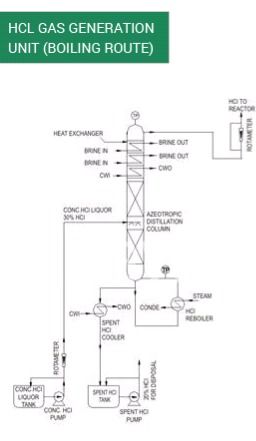

>> A pre-heated stream of 30% hydrochloric acid solution is fed to the azeotropic distillation column (C-1). Simultaneously a co-current feed of concentrated calcium chloride is also fed to the distillation column.

>> The calcium chloride breaks the azeotrope formed between HCl and water and as a result almost all the HCl available in the soln. is released as gas.

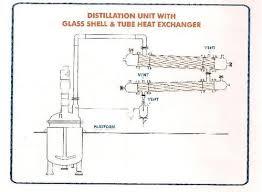

>> The heat exchangers (E-2 and E-4) are designed as thermosyphon reboilers where the heat energy for the distillation process and the evaporation process is supplied by steam.

>> The vapour from the reboiler strips the available gas from the feed acid soln. in the column. The top product HCl gas is dried in the Drying Unit using a suitable dehydrating agent. The moisture content in the product HCl gas is expected to be less than 0.001%.

>> The plant has been designed as a continuous process to produce dry HCl gas by the process of distillation of 30% hydrochloric acid solution along with a co-current stream of calcium chloride solution.

>> A pre-heated stream of 30% hydrochloric acid solution is fed to the azeotropic distillation column (C-1). Simultaneously a co-current feed of concentrated calcium chloride is also fed to the distillation column.

>> The calcium chloride breaks the azeotrope formed between HCl and water and as a result almost all the HCl available in the soln. is released as gas.

>> The heat exchangers (E-2 and E-4) are designed as thermosyphon reboilers where the heat energy for the distillation process and the evaporation process is supplied by steam.

>> The vapour from the reboiler strips the available gas from the feed acid soln. in the column. The top product HCl gas is dried in the Drying Unit using a suitable dehydrating agent. The moisture content in the product HCl gas is expected to be less than 0.001%.

Company Details

K-JHIL Scientific Pvt Ltd, Established in 1990 at Vapi in Gujarat, is a leading Exporter,Manufacturer,Supplier of Industrial Gas Plants in India. K-JHIL Scientific Pvt Ltd is one of Trade India's verified and trusted sellers of listed products. With extensive experience in supplying and trading Dry HCL Gas Generator Plant, K-JHIL Scientific Pvt Ltd has made a reputed name for itself in the market with high-quality Dry HCL Gas Generator Plant, Reaction Reflux Cum Distillation Unit, Solvent Recovery Plants, etc.

Focusing on a customer-centric approach, K-JHIL Scientific Pvt Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Industrial Gas Plants in bulk from K-JHIL Scientific Pvt Ltd at Trade India quality-assured products.

Focusing on a customer-centric approach, K-JHIL Scientific Pvt Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Industrial Gas Plants in bulk from K-JHIL Scientific Pvt Ltd at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

1990

Working Days

Monday To Sunday

GST NO

24ADTPK8527A1ZI

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24ADTPK8527A1ZI

Rating

Vapi, Gujarat

Technical Director

Mr. Ranvir Karakasia

Address

Plot No.: 198/2/A, Phase-II, Opp. Vapi Paper Mill, GIDC, Vapi, Gujarat, 396195, India

hcl gas generation unit in Vapi

Report incorrect details