- Tradeindia

- Packaging Machine

- Cement Packing Machine

Cement Packing Machine

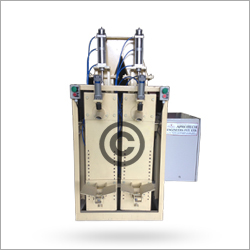

(63 products)Manual Mix Mortars Bag Filling System

Price: 402000 INR/Unit

MOQ1 Unit/Units

Voltage440 V AC Volt (v)

Automatic GradeManual

Product TypeMix Mortars Bag Filling System

Ss Or Ms Standard Powder Coating Automatic Grease Pouch Packaging Machine

Price: 162000 INR/Unit

MOQ1 Unit/Units

TypePackaging Line

MaterialSS or MS standard powder coating

Auxiliary Packaging Machine TypeOther

Voltage220 to 440 Volt (v)

Warranty1 year Manufaturing defect only

Mechanical Single Spout Cement Packing Machine - Automatic Grade: Automatic

Price: 230000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

TypePackaging Line

MaterialMild Steel

FeatureHighly Efficient

ComputerizedNo

Automatic GradeAutomatic

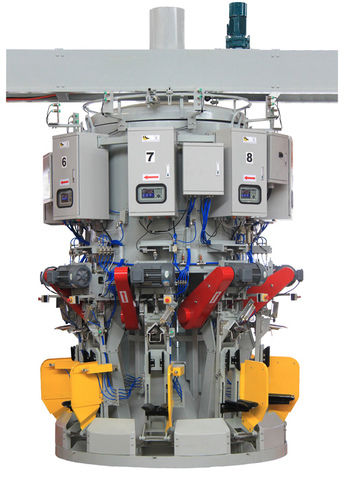

Two Spout Packing Machine - Attributes: Durable

Price: 650000 INR/Unit

MOQ1 Unit/Units

Weight1250 Kilograms (kg)

UsageIndustrial

SizeStandard

ConditionNew

Power SourceElectric

Voltage220-440 Volt (v)

Cement Packing Machine - Automatic Grade: Semi-Automatic

Price: 250000 INR/Unit

MOQ1 Unit/Units

ColorSilver

TypeFilling Machine

MaterialSS

FeatureHeavy Duty Machine, Durable, Rust Proof

ComputerizedNo

Automatic GradeSemi-Automatic

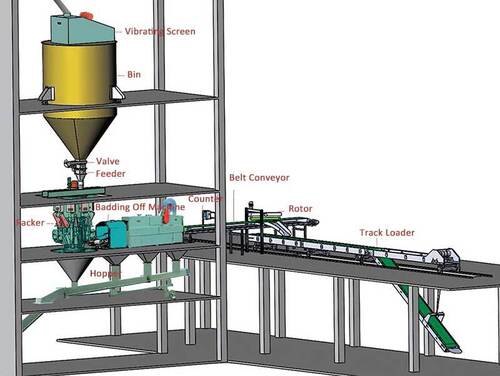

Industrial Cement Feeding System - Fly Ash Material, Semi-Automatic, Electric Drive, 440V | High Efficiency, Low Noise, Environmentally Friendly Automatic Control System

Price: 480000 INR/Pack

MOQ1 Unit/Units

Product TypeMannual Feeding

General UseCement & Fly Ash Feeding

MaterialFly Ash

Automatic GradeSemi Automatic

PLC ControlNo

Drive TypeElectric

Cement Packing Machine By Samnav Technologies

Price: 10000 INR/Piece

MOQ100 , Piece/Pieces

MaterialSS

ComputerizedNo

Automatic GradeAutomatic

Voltage220-240 Volt (v)

Warranty1 Year

Tuber Bottomer Machine Valve Sack Bag 50kg Cement Paper Bag Making Machine

Price: 585000 USD ($)/Set

MOQ1 Set/Sets

Product DescriptionTuber Bottomer Machine Valve Sack Bag 50kg Cement Paper Bag Making Machine

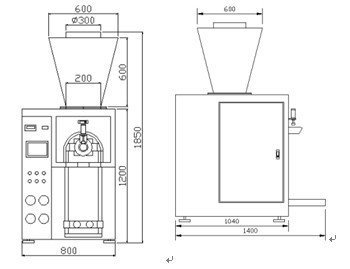

Single Spout Cement Packing Machine

Price: 800000.00 INR/Number

MOQ1 Unit/Units

MaterialSS

Auxiliary Packaging Machine TypeOther

Cement Bag Filling Machine - Automatic Grade: Semi-Automatic

Price: 250000 INR/Unit

MOQ1 Unit/Units

ColorBlue

MaterialMS

FeatureHighly Efficient, Less Power Consumable, Heavy Duty Machine, Durable, Rust Proof

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemHuman Machine Interface

Cement Packing Machine - Stainless Steel, Silver Color | High Efficiency, Durable & Heavy Duty, Low Maintenance

Price: 650000 INR/Unit

MOQ1 Unit/Units

Noise LevelLow

ApplicationCement Packing

Power Supply220-440V 50Hz

ColorGray, Other

Filling Range20-50 kg bags

FeaturesModular Design Easy Maintenance

Semi-Automatic Cement Bag Filling Machine

Price: 200000 INR/Unit

MOQ1 Unit/Units

ColorBlue

TypeFilling Machine

MaterialSS & MS

Auxiliary Packaging Machine TypeOther

Capacity15 to 50 T/hr

ComputerizedNo

Top Rated Products

Ss Or Ms Standard Powder Coating Automatic Grease Pouch Packaging Machine

Pharma Packaging Technology

Mechanical Single Spout Cement Packing Machine - Automatic Grade: Automatic

Vegam Engineers Private Limited

FAQs Related to Cement Packing Machine

Who are the top cement packing machine manufacturers in India?

- Aprotech Engineers Pvt. Ltd.

- Sigma Instrumentation

- Pharma Packaging Technology

- Priyanshi Fabricators & Engineers

- Unique Packaging Machines

- Samnav Technologies

- Despro Technologies Pvt. Ltd.

- Shivam Control Systems

- Vegam Engineers Private Limited

- Vineraj Weighing Automation

Which cities have the largest number of cement packing machine suppliers?

- Mumbai

- Delhi

- Jaipur

- Bengaluru

- Ahmedabad

- Faridabad

- Coimbatore

- Indore

- Rajkot

- Vadodara

- Thane

- Ghaziabad

- Secunderabad

- Jodhpur

- Meerut

- Qingdao

- Guangzhou

- Zhengzhou

- Wuhan

- Anqiu

What is the price range for cement packing machine offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| VEGAM ENGINEERS PRIVATE LIMITED | INR | Mechanical Double Nozzle Cement Packing Machine | 460000 |

| Technical Solution System | INR | Two Spout Cement Packing Machine | 800000 |

| SHIVAM CONTROL SYSTEMS | INR | cement bag filling machine | 250000 |

| SHREE GURU ENTERPRISES INDIA | INR | Cement Packing Machine | 125000 |

| Sensors & Systems Industrial Solution Pvt. Ltd. | INR | Cement Packing Machine | 650000 |

How many trusted sellers are available for cement packing machine?

- SIGMA INSTRUMENTATION

- PHARMA PACKAGING TECHNOLOGY

- VEGAM ENGINEERS PRIVATE LIMITED

- MM DESPRO ENGINEERING PVT. LTD.

- Titan Air Blowers

- SAMNAV TECHNOLOGIES

- DONG GUAN JOYDA TECHNOLOGY CO., LTD.

- APROTECH ENGINEERS PVT. LTD.

- SHIVAM CONTROL SYSTEMS

- UNIQUE PACKAGING MACHINES

What is the minimum order quantity for cement packing machine?

Do listed companies have registration & certifications?

- APROTECH ENGINEERS PVT. LTD.

- UNIQUE PACKAGING MACHINES

- VINERAJ WEIGHING AUTOMATION

- Henan GELGOOG Machinery Co., Ltd.

What is the get latest price feature?

What types of payment methods are accepted by the cement packing machine suppliers?

Cement Packing Machine - Electric Drive, Automatic Operation | Heavy Duty Design, Durable Performance

Price: 250000 INR/Unit

MOQ1 Unit/Units

TypeOther, Cement Packing Machine

FeatureHeavy Duty Machine, Durable

Automatic GradeAutomatic

Drive TypeElectric

Two Spout Cement Packing Machine - Automatic Grade: Semi-Automatic

Price: 800000 INR/Piece

MOQ10 Piece/Pieces

ColorBlue

TypeOther, Two Spout Cement Packing Machine

MaterialMild Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Voltage220 Volt (v)

Cement Packing Machine, Automation Grade: Semi-Automatic

Price: 125000 INR/Piece

MOQ1 Piece/Pieces

Payment TermsPaypal, Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

Supply Ability1000 Per Week

Delivery Time1 Week

Automatic Cement Packing Machine

Price: 550000 INR/, Unit

MOQ1 , Unit/Units

ColorSilver

MaterialMild Steel and Stainless Steel

Capacity500-1000 Kg/hr

ComputerizedYes

Automatic GradeAutomatic

Control SystemPLC Control

Cement Packaging Machines - Automatic Grade: Automatic

Price: 280000 INR/Unit

MOQ1 Unit/Units

ColorWhite

TypePackaging Line

MaterialStainless Steel

FeatureDurable

ComputerizedNo

Automatic GradeAutomatic

Cement Bag Packing Machine

Product DescriptionWe spend significant time in Exporting, Manufacturing and Supplying assortment of Laser Lamp For Sewing Machine (TD-12B) that are recognized among customers. These ranges are manufactured using best grade raw materials and leading-edge technologies to be sure its long lasting performances and durabi

Automatic White Cement Packing Machine

Price: 450000.00 INR/Unit

MOQ1 Unit/Units

ColorOther

TypeOther

FeatureRust Proof, Durable

Automatic GradeAutomatic

Drive TypeElectric

Cement Packing Machine - Fully Automatic 15-18 Tons/Hour Output, 1 to 6 Filling Spouts, No Stitching Required, Ideal for Jute, HDPE, or Paper Bags

Price: 225000 INR/Unit

MOQ1 Unit/Units

ColorWhite

TypeFilling Machine

MaterialPowder, Cement, Fertilizer, Spices, Grains, Rice, Wheat, Dals, Cereals, Flour, Atta, Sugar, Salt

FeatureBeverage, Food, Textiles, Commodity, Medical, Chemical

ComputerizedNo

Automatic GradeAutomatic

Cement Packing Machine - High-Degree Automation, Intelligent Recognition System | Efficient Bag Filling, Reduced Labor Intensity, Improved Production Efficiency

Product DescriptionWe are engaged in manufacturing and supplying excellent quality Cement Packing Machine in Zhengzhou, Henan, China. Three Spout Cement Filling Packing Machine can automatically realize bags pressing, filling, release, stop filling and swap bags and other functions, stable performance, simple operatio

Automatic High Performance Rotary Cement Packer

Price Trend: 40000.00 - 40000.00 USD ($)/, Set

MOQ1 , Set/Sets

TypePackaging Line

Capacity80-160T/H Kilogram(Kg)

ComputerizedYes

Automatic GradeAutomatic

Control SystemHuman Machine Interface

Automatic Sealing Machine - Application: Industrial Use

Price: 150000 INR/Piece

MOQ1 Piece/Pieces

ApplicationIndustrial use

TypeAutomatic Sealing Machine

ConditionNew

ColorBlue

Driven TypeElectric

Cement Packing Machine - Feature: Environment Friendly

Price: 250000 INR/Unit

MOQ1 Unit/Units

Product TypeCement Packing Machine

General UseIndustrial use

AutomaticYes

Drive TypePneumatic

FeatureHigh Quality, Environment Friendly

Cement Packing Machine - Stainless Steel, Compact Design, Blue Color | Highly Efficient, Heavy Duty, Automatic Valve Port with Impeller and Screw Type Discharging

Price: 250000 INR/Unit

MOQ1 Unit/Units

ColorBlue

TypeOther, Cement Packing Machine

MaterialStainless Steel

FeatureHighly Efficient, Heavy Duty Machine

ComputerizedNo

Automatic GradeAutomatic

Automatic Rotary Cement Packing Machines By Tangshan Zhineng Electronics Co.,Ltd.

Product TypeCement Packing Machine

ColorOrange

MaterialMetal

Weight5500KG

Dimension2450*2450*3100MM

VoltageAC 380V

Stainless Steel Cement Packing Machine - 1800 x 1200 x 700 Mm, Automatic Grade with Heavy-Duty Design and 30 Pcs/min Capacity

Price: 325000 INR/Unit

MOQ1 Unit/Units

ColorSilver

TypeOther, Cement Sand Packing Machine

MaterialStainless Steel

FeatureHeavy Duty Machine

Capacity30 Pcs/min

ComputerizedYes

Cement Packing Machine - Automatic Electric Driven, Highly Efficient & Durable, Rust Proof Design

Price: 550000 INR/Unit

MOQ1 Unit/Units

TypeFilling Machine

FeatureHighly Efficient, Less Power Consumable, Durable, Rust Proof

Automatic GradeAutomatic

Drive TypeElectric

Latest from Cement Packing Machine

Automatic 1800 X 1200 X 700 Mm Stainless Steel Cement Sand Packing Machine

325000 INR

By:

Frigmaires Engineers

Low Maintenance and Easy Operation Cement Packaging and Loading Plant

By:

Kashish Engineering

Explore More Cities

Ready To Ship Cement Packing Machine

What Makes Cement Packing Machines So Efficient For the Construction Industry?

Cement packaging machines are vital equipment in the construction and mining industry as they widely use cement products. The level of speed, accuracy, and automation cement packaging machines offer is remarkable for improving productivity. Moreover, these machines also reduce manual labor expenses streamlining the packaging process. With automation, the cement packing process becomes dust-free, and safe, and eliminates the chances of human errors. Also, it creates a much more safe working environment for the operators and surrounding workers.

Benefits of Cement Packaging Machine

-

Bag Filling

Cement packaging machines automate the process of filling bags with cement. This ensures uniform weight and reduces manual labor, increasing the efficiency of the packaging process.

-

Sealing

These machines can seal the filled bags, ensuring that the cement is securely enclosed, reducing spillage and contamination during transportation and storage.

-

Weighing

Cement packaging machines are equipped with weighing systems to ensure each bag contains the precise amount of cement, which is crucial for maintaining product consistency and meeting regulatory standards.

-

Labeling

Some machines come with integrated labeling systems to print and attach labels that include important information such as batch number, weight, manufacturing date, and brand details, facilitating product tracking and quality control.

-

Palletizing

Advanced cement packaging systems can include palletizing units that stack filled and sealed bags onto pallets for easy handling, storage, and transportation. This minimizes manual handling and improves workplace safety.

-

Dust Control

These machines often have dust extraction systems to minimize dust generation during the filling and sealing process, maintaining a cleaner working environment and protecting workers' health.

-

High-Speed Production

Cement packaging machines are designed for high-speed operation, which is essential for large-scale cement production facilities to meet high demand efficiently.

-

Custom Bag Sizes

They can handle various bag sizes and types, providing flexibility in packaging different quantities of cement to meet diverse market needs.

-

Automation Integration

Modern packaging machines can be integrated into automated production lines, allowing for seamless operation and monitoring of the entire packaging process, from filling to palletizing.

-

Quality Control

These machines ensure consistent packaging quality, which helps maintain brand reputation and customer satisfaction by delivering products that meet specified standards.

-

Safety Features

These include emergency stop buttons, safety guards, and interlocks to protect operators and ensure the safe operation of the machine.

Major Components of Cement Packaging Machine

-

Hopper

This is the initial storage area where cement is fed into the machine. It ensures a continuous supply of cement to the packaging system.

-

Feeder

The feeder controls the flow of cement from the hopper to the bag-filling section. It ensures that the correct amount of cement is delivered for each bag.

-

Weighing System

This component measures the exact weight of cement to be filled into each bag, ensuring consistency and accuracy. It often includes load cells or weighing scales.

-

Bagging Unit

This is where the bags are filled with cement. It typically includes a spout or nozzle that directs the cement into the bags. The design of this unit can vary based on whether it is for valve bags, open-mouth bags, or other types of packaging.

-

Bag Holder or Clamp

This component holds the bag securely in place during the filling process, preventing spillage and ensuring that the cement is directed into the bag correctly.

-

Filling Spout

The filling spout directs cement from the feeder into the bag. It is designed to fit securely into the bag opening, minimizing spillage and dust.

-

Sealing Mechanism

Once the bag is filled, this component seals the bag. The method of sealing can vary, including heat sealing, sewing, or crimping, depending on the type of bag used.

-

Dust Extraction System

This system collects and removes dust generated during the filling process, maintaining a clean working environment and protecting worker health.

-

Conveyor System

After the bags are filled and sealed, they are transported via conveyors to the next stage of the packaging process, such as palletizing. Conveyors ensure smooth and efficient movement of the bags.

-

Control Panel

The control panel is the interface for operators to manage and monitor the packaging machine. It allows for setting parameters like bag weight, filling speed, and other operational settings. Modern systems may include touchscreens and programmable logic controllers (PLCs) for automation.

-

Palletizer

This optional component stacks the filled and sealed bags onto pallets for easy handling, storage, and transportation. Palletizers can be manual, semi-automatic, or fully automatic.

-

Labeling System

An integrated labeling system can print and apply labels to each bag, providing important information such as batch numbers, weight, and manufacturing dates.

How to Choose a Cement Packaging Machine For Yourself?

-

Determine Your Packaging Needs

Start by assessing your production volume, including daily, weekly, and monthly output needs. Select a machine that can handle your desired capacity efficiently. Ensure the machine can accommodate the specific bag sizes and types you use, such as valve or open-mouth bags.

-

Consider Automation Level

Manual machines are affordable but labor-intensive, while fully automatic machines offer high efficiency and minimal labor costs. Choose the level of automation that best fits your operational needs.

-

Accuracy and Precision

Ensure the machine provides precise weighing to avoid overfilling or underfilling bags, which can lead to product wastage and customer dissatisfaction. Investing in a machine with high precision will reduce waste and enhance customer satisfaction.

-

Durability and Maintenance

Select a machine made from high-quality, durable materials to withstand the abrasiveness of cement. Regular maintenance is essential to keep the machine running efficiently and prolong its lifespan.

-

Cost and ROI

Evaluate the cost of the machine against its potential return on investment. Consider long-term benefits like efficiency, lower maintenance costs, and higher production capacity.

Client Testimonials & Reviews

HarinderKumar

STAR PACKAGING SYSTEMS

We have been associated with tradeindia.com from last 7 years. A genuine company which actually provides the services they offer through a helpful staff. Highly recommended to anyone looking to start or expand business joint with tradeindia. It is a very good platform to export ourselves. Thanks tradeindia.com.

Kalpesh

PURUSHARTH PACKAGING

We are associated with tradeindia since last 7 years. We are much satisfied with the service and response from tradeindia. We are having many client through online marketing. We wishes best future for tradeindia

SureshSisodiya

DURGA PACKAGING MACHINE

We are the member of tradeindia.com. We are getting very good inquiry/responses through tradeindia.com, We are satisfied with the support of CRM department. We looking forward the same kind of support and relationship from tradeindia and wishing them best for their future.

AshishJoshi

ASHUTOSH ENTERPRISE

We are the member of the tradeindia.com for the last six years. We have good inquiries through tradeindia.com, we are satisfied by the services and inquiry received by tradeindia.com. We are looking forward the same kind of support and relationship from tradeindia.com. We wish all the best for the tradeindia.com for the future.

BhaveshMehta

MONARCH APPLIANCES PRIVATE LIMITED

We are leading manufacturer of Packaging Machinery. We are associated with tradeindia since 11 years. We are very satisfied with the response getting through tradeindia. We would really like to appreciate the working of tradeindia.com and their team members. We would like to continue with them in the ensuring years. We wish you all Good Luck in their future endeavors.

VinayJAIN

APROTECH ENGINEERS PVT. LTD.

We are associated with tradeindia for past twenty years. During this period, we are regularly getting enquiries and hence renewing our contract continuously. Tradeindia are competitive in the field.

SanjaySabharwal

UFLEX LIMITED (ENGINEERING DIVISION)

We are the manufacturer and exporters of Packaging and converting machinery based at Noida, India. We are regular Advertiser of tradeindia.com and getting relevant inquiry. We are satisfied from the service provided by tradeindia.com. We Wish all the very best to tradeindia family for an excellent future.

Ch. UmaRao

PRESTO PACK SYSTEMS PVT. LTD.

We have been associated with tradeindia since more than 10 years and we feel happy to say that their services have been excellent during our courtship and has become our effective marketing tool to explore Domestic and International Market. We wish to continue with their improving services in years to come. We would like tradeindia to keep this good work and promote the Indian Market more. All the Best for tradeindia team.

K.Srinivas

CANFLEX ENGINEERING PVT. LTD.

We, M/S Canflex Engineering (manufacturers of Packaging Machinery) are proud to be associated with M/S Infocom Network Ltd, Since 10 years. We are having good business relationship till date and in hope to continue the same in near future too. We, wish that your company continues to contribute more to promote our products in Domestic as well as International markets.

Fakharuddin

SARA UDYOG

We are Manufacturer and Exporter of Auger filler machines, Automatic filling and packing machine, Automatic pneumatic packing machine, Band sealer, coding pan, Collar type machine, Drum roster, Liquid mixer machine, Manual padal sealing, Pouch packing machine with Auger filler, Packaging Machine, Snax food scooder machine, Collar type filler, Line packaging machine, Masala packaging machine, Chips Plant, Gutaka plant, Kurkure machine plant, Namkeen plant, Food processing machine, Tea packaging machine. We are working on enquiry on daily basis, we are satisfied with tradeindia services this is one of the good B2B portal. We are getting relevant enquiry. We wish all the very best to tradeindia family for their excellent future.

Cement Packing Machine Price List

Product Name | Expected Price |

|---|---|

| Mechanical Double Nozzle Cement Packing Machine | 460000 |

| Mechanical Single Spout Cement Packing Machine | 230000 |

| Single Spout Cement Packing Machine | 280000 |

| Double Nozzle Electronic Cement Packing Machine | 660000 |

| Cement Packing Machine | 350000 |

| Double Nozzle Cement Packing Machine | 660000 |

| Two Spout Cement Packing Machine | 800000 |

| cement bag filling machine | 250000 |

| Cement Packing Machine | 125000 |

| Cement Packing Machine | 650000 |

This Data was Last Updated on 2025-04-22

Cement Packing Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Aprotech Engineers Pvt. Ltd. Faridabad, India | 23 Years |

Sigma Instrumentation Ahmedabad, India | 15 Years |

Pharma Packaging Technology Thane, India | 15 Years |

Priyanshi Fabricators & Engineers Ahmedabad, India | 11 Years |

Unique Packaging Machines Jaipur, India | 10 Years |

Samnav Technologies Ghaziabad, India | 9 Years |

Despro Technologies Pvt. Ltd. New Delhi, India | 8 Years |

Shivam Control Systems Vadodara, India | 5 Years |

Vegam Engineers Private Limited Ghaziabad, India | 4 Years |

Vineraj Weighing Automation Vadodara, India | 4 Years |

Upcoming Tradeshows

FoodTech Kerala 2025

Thu, 22 May, 2025 - Sat, 24 May, 2025

Copper China 2025

Wed, 09 Jul, 2025 - Fri, 11 Jul, 2025

INDIAN ICE CREAM CONGRESS & EXPO 2025

Mon, 06 Oct, 2025 - Wed, 08 Oct, 2025

India Hospitality + F&B Pro Expo - Goa 2025

Fri, 09 May, 2025 - Sun, 11 May, 2025

Smart Home Expo 2025

Thu, 08 May, 2025 - Sat, 10 May, 2025

CPHI & PMEC China 2025

Tue, 24 Jun, 2025 - Thu, 26 Jun, 2025

International Crop Science Conference and Exhibition 2025

Tue, 10 Jun, 2025 - Wed, 11 Jun, 2025

WORLD OF HOSPITALITY EXPO 2025

Thu, 12 Jun, 2025 - Sat, 14 Jun, 2025

MachAuto 2025

Fri, 25 Jul, 2025 - Mon, 28 Jul, 2025

Asia Labex 2025

Wed, 11 Jun, 2025 - Fri, 13 Jun, 2025

Popular Categories