Control Panel Boards

(18948 products)Product Showcase

Instrumentation Pneumatic Control Panel - Mild Steel & Iron | 220-240V Insulation, Elegant White Finish, 1-Year Warranty, Advanced Control Efficiency

Price: 50000 INR/Piece

MOQ1 Piece/Pieces

Cover MaterialIron

Base MaterialMild Steel

Surface ColorWhite

Rated Insulation Voltage220-240 V

Product TypeControl Box

MaterialMild Steel

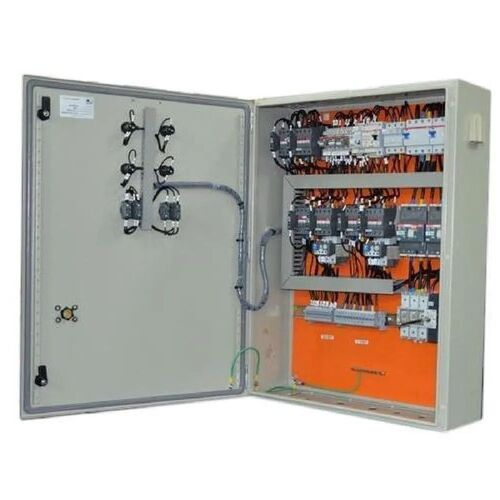

Siemens Power Control Center Panel - Base Material: Mild Steel

Price: 100000 INR/Kilowatt

MOQ1 , Number

Base MaterialMild Steel

Way2 Way

Protection LevelIP66

MaterialStainless Steel

Surface FinishPainted

Frequency (MHz)50 Hertz (HZ)

Naksh Technology Solution Llp

Ahmedabad

Control Panel Board - Cover Material: Stainless Steel

Price: 250000.00 INR/Unit

MOQ1 Unit/Units

Surface ColorWhite

Cover MaterialStainless Steel

MaterialStainless Steel

Surface FinishPowder Coated

Rated Voltage90.5 Watt (W)

Frequency (MHz)50 Hertz (HZ)

Zaral Electricals

Vadodara

Super Premium

Super Premium10 Years

Super Premium

Super PremiumElevator Car Operating Panel - Speed: 0.3Mps M/S

Price Trend: 100000.00 - 500000.00 INR/Piece

MOQ1 Piece/Pieces

Power Supply440VOLTS

Speed0.3MPS m/s

Electric Panel 7 Inch Cnc Plasma Machine Controller

Price: 60000 INR/Piece

Product TypeElectric Panel

WarrantyManufacturer Warranty

CNC Mill Learning System

Price: 25000 INR/Unit

MOQ1 Pack/Packs,

Supply Ability10 Per Month

Delivery Time10-30 Days

Packaging DetailsExport Worthy

Didac International

New Delhi

Trusted Seller

Trusted Seller10 Years

230 V Medical Isolation Panel Base Material: Mild Steel

Price: 3000000 INR/Unit

MOQ1 Unit/Units

Base MaterialMild Steel

Cover MaterialMetal Base

Surface ColorWhite

Product TypeControl Box

MaterialMild Steel

Surface FinishPainted

Fabric Dyeing Machine Control Panel

Price Trend: 200000.00 - 500000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability10 Per Month

Delivery Time2-12 Week

R. B Electronic & Engineering Pvt. Ltd.

Chanod

Isolationtransformer Control Panel - Base Material: Metal Base

MOQ1 Unit/Units

Way2-3 Way

Base MaterialMetal Base

Protection LevelIP65

MaterialMetal Base

Surface FinishGI Galvanized

Warranty1 Year

Ests Power Transformer Private Limited

Ghaziabad

Oxygen Fully Automatic control Panel

Price: 75000 INR/Number

MOQ1 Number

Supply Ability5 Per Day

Delivery Time2 Days

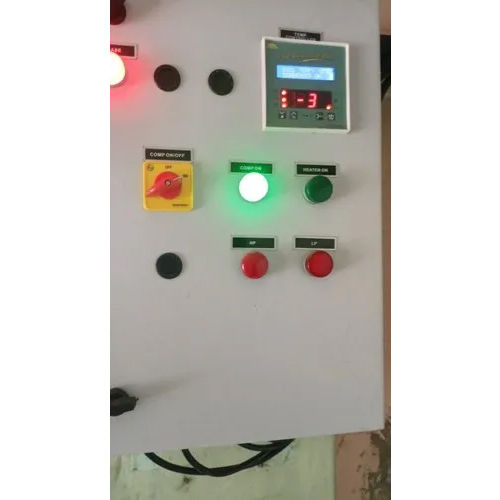

Control Panel For Cold Room - Base Material: Mild Steel

Price: 15500 INR/Unit

MOQ1 Unit/Units

Surface ColorAny Color

Base MaterialMild Steel

MaterialMild Steel

Surface FinishPowder Coated

Rated Voltage220/440 Volt (V)

Frequency (MHz)50 Hertz (HZ)

Chromatography Gas Purification Panel - Mild Steel, 220-440 Volt | White Powder Coated Surface, Warranty Included

Price: 22200 INR/Unit

MOQ1 Unit/Units

Surface ColorWhite

Product TypeControl Box

MaterialMild Steel

Surface FinishPowder Coated

Rated Voltage220-440 Volt (V)

WarrantyYes

Control Panel For EOT Crane - Mild Steel Material, Powder Coated Finish, Any Color Options | High-Quality Performance and Durability

Price: 100000 INR/Unit

MOQ1 Unit/Units

Base MaterialMild Steel

Surface ColorAny Color

Product TypeOther, Crane Control Panel

MaterialMild Steel

Surface FinishPowder Coated

Silverline Metal Engineering Pvt. Ltd.

Mumbai

Metal Crane Master Controller

Price Trend: 2000.00 - 5000.00 INR/Unit

MOQ1 Unit/Units

Product TypeMaster Controller, Other

MaterialMetal

Powerline Crane Systems Private Limited

Ahmedabad

Control Panel For Eot Cranes Base Material: Metal Base

Price: 50000.00 INR/Piece

MOQ1 Piece/Pieces

Cover MaterialMetal Base

Base MaterialMetal Base

Surface ColorBlack

Product TypeControl Box

MaterialOther

Surface FinishPowder Coated

Derrick Engi Works Private Limited

Ahmedabad

Ring Main Unit - Efficiency: 99%

Price: 300000 INR/Unit

MOQ01 Unit/Units

Product TypeDry Type Transformer

MaterialMS

OutputAC

Frequency (MHz)60 Hertz (HZ)

Efficiency99%

PhaseThree Phase

Unitized Substation Transformer - Rated Voltage: 415V Volt (V)

MOQ10 Piece/Pieces

Product TypeOther, Unitized Substation Transformer

Surface ColorWhite

Rated Voltage415V Volt (V)

Warranty1 Year

Gujarat Plug-in Devices Pvt. Ltd.

Vadodara

Electrical Control Panels - Mild Steel, White Powder Coated Finish | Rated Current 220-440 Volt, Frequency 50-60 Hertz, 1-Year Warranty

MOQ1 Unit/Units

Rated Current220-440 Volt (v)

Product TypeOther, Electrical Control Panels

MaterialMild Steel

Surface FinishPowder Coated

Surface ColorWhite

Frequency (MHz)50-60 Hertz (HZ)

Three Phase Power Control Panel Cover Material: Stainless Steel

MOQ10 Unit/Units

Cover MaterialStainless Steel

MaterialMild Steel

Surface FinishGI Galvanized

StandardFirst Class

WarrantyYes

Cess Automation India Llp

Ahmedabad

Servo Controller - Metal Base, 15Kw Power, 50-60Hz Frequency | 220-440V Rated Current, 1-Year Warranty, Industrial Use

MOQ1 Unit/Units

Cover MaterialMetal Base

Rated Current220-440 Volt (v)

Product TypeOther, Servo Controller

MaterialMild Steel

Frequency (MHz)50-60 Hertz (HZ)

Warranty1 Year

Pvc Power Contactors

Price: 500 INR/Piece

MOQ5 Piece/Pieces

Product TypeSwitchgear

MaterialPVC

Surface ColorWhite

Rated Voltage24,110,220,415 VAC Ampere (A)

Maximum Output Current6A TO 630 Biot ( Bi)

Warranty18 ONTHS

Servo Drive Panel Board - Base Material: Mild Steel

Price: 75000 INR/Piece

MOQ2 Unit/Units

Surface ColorBlue

Base MaterialMild Steel

Protection LevelIP65

Cover MaterialStainless Steel

MaterialMetal

Surface FinishPowder Coated

Zentech Automation

Delhi

Super Seller

Super Seller13 Years

Industrial Ring Main Unit - IP65 Rated Protection, 440V Voltage, 220A Current | Powder Coated Finish, Maximum Output 630A, Warranty Included

Price: 175000 INR/Unit

MOQ1 Unit/Units

Protection LevelIP65

ThicknessDifferent Available Millimeter (mm)

Rated Current220 Volt (v)

Surface FinishPowder Coated

Rated Voltage440 Volt (V)

Frequency (MHz)50 Hertz (HZ)

Aluminium Clamp and Connectors

Product DescriptionClients typically desired to buy quality items, so we are populated with Exporting, Manufacturing, Distributing, Supplying and Trading a best nature of Aluminium Clamp and Connectors in Ahmedabad. These are utilizing ideal quality material and exceedingly tried for their quality in different variabl

Electrical Control Panel Board Base Material: Metal Base

Price Trend: 50000.00 - 60000.00 INR/Piece

MOQ100 Piece/Pieces

Base MaterialMetal Base

Cover MaterialMetal Base

Product TypeOther, Electrical Control Panel Board

MaterialMetal

Surface ColorGrey, Other

WarrantyYes

Three Phase DOL Starter Control Panel - Mild Steel & PVC, IP65 Protection Level, White Painted Finish, 50-60 Hz Frequency, Warranty Included

Price: 15000 INR/Unit

MOQ10 Unit/Units

Protection LevelIP65

Surface ColorWhite

Cover MaterialPVC

Base MaterialMild Steel

Product TypeOther, Three Phase DOL Starter Control Panel

MaterialPVC

LT Panel - Mild Steel Electric Panel, Standard Dimensions, Any Color, Powder Coated Finish

Price: 600000 INR/Box

MOQ2 Box/Boxes

Base MaterialMild Steel

Surface ColorAny Color

Product TypeElectric Panel

MaterialMild Steel

Surface FinishPowder Coated

Dimension (L*W*H)Standard Millimeter (mm)

Shiv Shakti Engineering

Mumbai

Super Seller

Super Seller15 Years

Industrial Electrical Control Panel - Metal, Rated Voltage 220-440V | Warranty Included, White Surface Finish

Price: 350000 INR/Unit

MOQ1 Unit/Units

Surface ColorWhite

Product TypeElectric Panel

MaterialMetal

Rated Voltage220-440 Volt (V)

WarrantyYes

Latest From Control Panel Boards

Explore More Cities

Ready To Ship Control Panel Boards

Understanding Control Panel Board Basics

An electrical control panel is an enclosure, usually made of metal or plastic, that houses crucial electrical parts that regulate and observe a variety of mechanical operations. They are powered systems that require maintenance, with condition-based monitoring and planned preventative maintenance being the most efficient approaches. In order to diagnose problems, make modifications, and verify electrical safety, electrical personnel must acquire access to control panels. To run and manage the plant and process, operators will interact with the panel's controls. The control panel's components will make a variety of activities easier. For instance, they may monitor the pressure or flow in a pipe and signal when to open or shut a valve. They are typical and essential to the majority of enterprises. Neglecting them can lead to issues with them.

Designing Control Panel Boards for Optimal Performance

Component layout and placement

Components and component groups should be arranged logically and functionally in any control panel. For instance, since the primary incoming power disconnect switch is typically located near the top right of control panels, components with a high voltage rating should be positioned at the top of the panel. Power components will have a reduced voltage level as you descend the control panel.

Power distribution components should have a breaker for the designated power level to the left, followed by distribution breakers, fuses, and terminals in order to make troubleshooting simpler. This will maintain order, consistency, and reflect the schematic hierarchy. Between groups, there should be enough room to facilitate easy expansion.

Let’s have a look at the strategies for designing control panels

1. Adopt a different leaner style

Finding strategies to make space available is usually helpful in manufacturing. Even if there aren't any urgent requirements for new equipment right now, they most likely will be in the near future. Narrower and lighter control panels can help free up more space for future expansion and the inclusion of more components.

2. Enhance the dissipation of heat

A control panel's longevity can be severely impacted by improper heat dissipation. The maintenance and/or replacement downtime brought on by defective panels can drastically reduce productivity. The air circulation within control panels must be optimised in order to lessen hot spots.

3. Make wiring easy safe and secure

Wires are held firmly in place by Omron's Innovative Push-In Plus technology, which offers a strong grip. Even more amazing about this technology is how it combines a strong pull-out force with a remarkably weak insertion force. In fact, putting a wire into a Push-In Plus terminal block requires less effort than plugging in a standard pair of earbuds.

The function of a control panel boards

PANEL FOR ELECTRICAL CONTROL ELECTRICAL PARTS

Within a utilised electrical panel enclosure, there are eight main sorts of electrical components that define and organise the many functions the panel performs. These elements consist of:

Circuit breaker in the main- This is comparable to disconnecting the main electrical panel that serves a building's entrance or office. In the majority of industrial applications, miniature circuit breakers handle voltages between 120V and 480V, establishing control over circuit components.

Influx arresters- This part shields the electrical components inside the panel from overvoltage damage caused by lightning strikes or utility power surges.

Transformers- Transformers can step down voltage to 24V when incoming power is 120V or reduce voltage to 120V for various components depending on the incoming voltage.

Safety Tips for Working with Control Panel Boards

Electricity is required for everything from facility lighting to operating gear and equipment. The industrial control panel is at the centre of how the office uses energy. The labelling of the electrical panel is frequently disregarded for unknown reasons. It is crucial that employees are aware of where to go in order to quickly and securely solve any electrical equipment issues.

Observation of Details

According to the Bureau of Labor and Statistics, 154 people died in 2016 as a result of electrical exposure. Shock and arc flash injuries are frequent when dealing with electricity. Employers cannot entirely eliminate dangers unless they stop using electricity. Employee protection can be achieved, nevertheless, by following safety best practises such employing the appropriate personal protective equipment (PPE), lockout/tagout techniques, and current electrical equipment identification.

Maintain Current Communications

Control panels are highlighted by floor signs and tape.

Each piece of service equipment, including motor control centers, panels, feeders, substations, and switchboards, needs to be labelled. When equipment that may be unmarked or labelled with outdated information needs to be maintained or repaired, proper labelling impacts the safety of everyone in the facility both now and years from now. In the event that emergency personnel need to access facility equipment during a disaster response, industrial control panel labelling is also helpful.

Shock and arc flash injuries are frequent when dealing with electricity. Employers cannot entirely eliminate dangers unless they stop using electricity. Employee protection can be achieved, nevertheless, by following safety best practises such employing the appropriate personal protective equipment (PPE), lockout/tagout techniques, and current electrical equipment identification.

Applications of Control Panel Boards in Various Industries

MCCs

MCCs, often referred to as motor control centers, have one or more vertical cabinet portions that have mounting points for motor controllers and a busbar for power distribution. A contactor or motor starter, an overload relay to safeguard the motor, circuit protection tools such circuit breakers and fuses, and a power disconnect switch are all included in each motor controller in an MCC panel.

MCC panels may also include other controls elements such pushbuttons, indicator lights, programmable logic controllers (PLCs), variable frequency drives (VFDs), and metering devices. Large production plants that require the control of several motors from a central area, such as a mechanical or electrical room, frequently install MCCs.

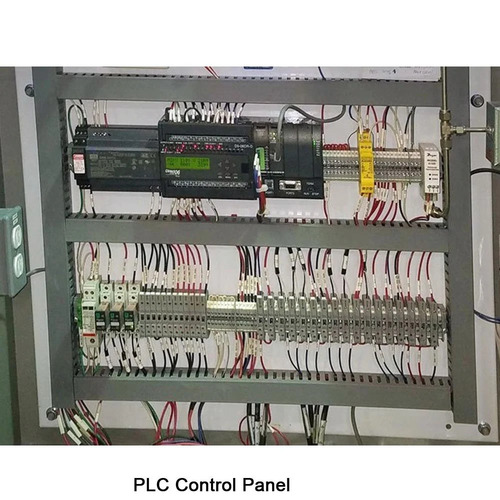

Panels for PLC Control

PLCs are commercial computers that link and keep an eye on relays, pushbuttons, sensors, and other input devices. The PLC can carry out pre programmed outputs such sounding an alarm, opening or closing a valve, or stopping or starting a motor based on the status of an input device.

VFD Management Panels

VFDs are a form of motor controller that are used to modify the input voltage and frequency to control motor speed. When starting or halting a motor, VFDs can additionally regulate the ramp-up and ramp-down phases. The efficiency of the system is increased, energy consumption is decreased, the motor's speed and torque are matched to the needs of the process, and mechanical stress on a machine is minimised thanks to VFDs.

A single or several VFDs, power distribution components, circuit and motor protection devices, line reactors or harmonic filters, motor starters, and a PLC can all be found in a VFD control panel.

Panels for motor starters

Motor starters are tools that start and stop a motor using electromagnetic forces. An overload relay is typically part of a motor starter system to safeguard the associated motor from electrical overload. A motor starter panel may include one or more motor starters that are enclosed, together with pushbuttons or selector switches to control the motor's status, circuit protection devices, power distribution components, and a power disconnect switch.

Troubleshooting Common Problems with Control Panel Boards

If you take your time, control panel troubleshooting can be completed effectively. This doesn't make sense because you're normally debugging a control panel in a production setting where you need to have the issue resolved right away. Prepare your attack. Spend no time or energy in vain. Find the quickest route to the answer. Here are the fundamentals.

Ask for help

Before taking any action, ask for assistance if you can. Sometimes you're fortunate. Speak to anyone who has knowledge of the control panel or the machinery it governs. Contact the maker of the machinery. You're trying to find someone who understands how the control panel should operate.

Utilize your options

Toolkit for debugging the control panel

MANUALS - Look for the manuals that were initially provided with the control panel. Installation and operating instructions are typically included with control panels. Drawings of electrical schematics are useful. Call the manufacturer to request a copy of the paperwork if you can't find it.

Focus on your efforts

Before you do anything, locate the dedicated power source that is supplying the control panel. In a motor control centre or electrical power distribution panel, it is typically a specialised circuit breaker. Locate it, shut it off, and then look for any field devices that are linked to the panel. The power circuits are a good place to start if you're unsure where.

FAQs: Control Panel Board

Q. What is a control panel board?

Ans. A control panel board is a device that houses different electric devices for regulating and managing machines and production lines, protecting against anomalies, and operating heaters and electric motors like pumps and motors.

Q. What are the different types of control panel boards?

Ans. There are three types of control panels

- Power Control Center (PCC Panel)

- Motor Control Center (MCC Panel)

- Automation Panel (SCADA PLC Panel)

Q. What are the main components of a control panel board?

Ans. Every automated manufacturing process needs electrical control panels. Basic control panels contain a variety of electrical components that send signals to guide the functioning of machinery and equipment. Even though control systems are a crucial component of electrical engineering, many individuals are unaware of the essential parts that a reliable and safe control panel must include.

Q. How do you select the right control panel board for a particular application?

Ans. Printed circuit boards with connections to all nearby peripheral devices are typically housed inside control panels. Door hardware, such as a card reader, door position switch, or door strike, as well as additional inputs and relays as needed, may be included in these peripheral devices. The control panel interfaces with the host computer and hosts the management of the peripheral devices.

Manufacturers & Suppliers of Control Panel Boards

Company Name | Member Since |

|---|---|

Jindal Rectifiers Faridabad, India | 20 Years |

Silverline Metal Engineering Pvt. Ltd. Mumbai, India | 18 Years |

Jsn Enterprise Vadodara, India | 15 Years |

R. B Electronic & Engineering Pvt. Ltd. Chanod, India | 15 Years |

National Power Industries Ahmedabad, India | 15 Years |

Shreeji Enterprises Mumbai, India | 15 Years |

Shiv Shakti Engineering Mumbai, India | 15 Years |

Zentech Automation Delhi, India | 13 Years |

Gujarat Plug-In Devices Pvt. Ltd. Vadodara, India | 12 Years |

Tolas Elevators Jaipur, India | 11 Years |

Popular Products