Hex Bolts

(2804 products)Hexagonal Bolt Application: As A Dopant In Semiconductors

Price: 2 INR/Piece

MOQ2000 Piece/Pieces

ColorSilver

Product TypeBolts

UsageIndustrial

Vinay Engineering Company

Vasai

Trusted Seller

Trusted Seller8 Years

Premium Seller

Premium SellerStainless Steel Hex Bolts Application: Industrial

Price: 22 INR/Piece

MOQ100 Piece/Pieces

SizeAvailable in different sizes

ColorSilver

Head TypeFlat Hexagonal

Product TypeStainless Steel Hex Nuts And Bolt

Surface TreatmentPlating

MaterialStainless Steel

Nandika Fasteners

New Delhi

Trusted Seller

Trusted Seller7 Years

Super Seller

Super Seller304L Stainless Steel Hex Bolt Dimensions: 8 - 16 Mm Millimeter (Mm)

Price: 30 INR/Piece

MOQ100 Piece/Pieces

Dimensions8 - 16 mm Millimeter (mm)

FinishNickel Plating

Ibk Engineers Pvt. Ltd.

Bengaluru

Trusted Seller

Trusted Seller11 Years

Premium Seller

Premium SellerRegular Head Mild Steel Full Thread Galvanized Zinc Electroplating Hex Head Bolts Use: Use In Fittings

Head TypeRegular, Other

ColorSilver

Product TypeBolt

UseUse in fittings

Sizefrom 1/4 inch to 4 inches

FinishGalvanized

Parmar Steel

Mumbai

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerStainless Steel Hex Bolt Diameter: 3 To 50 Millimeter (Mm)

MOQ100 Piece/Pieces

Diameter3 TO 50 Millimeter (mm)

Heat TreatmentOther

Head TypeHexagon

UseINDUSTRIAL

FinishOther

StandardDIN, ASTM, ISO

S.h.industrial Needs

Chennai

Trusted Seller

Trusted Seller6 Years

Premium Seller

Premium SellerAIRA Hex Bolts

Product DescriptionIn order to provide the full satisfaction to our customers, we are engaged in exporting, trading and supplying Hex Bolts as a part of our huge collection of highly qualitative fasteners by being centered in Bengaluru, Karnataka, India. Bolts with a hexagonal head with threads for use with a nut or

Aira Trex Solutions India Private Limited

Bengaluru

Trusted Seller

Trusted Seller4 Years

Super Seller

Super SellerHex Bolt

MOQ100 Piece/Pieces

Sample AvailableYes

Sample PolicyFree samples are available

Main Domestic MarketAll India

Morex Enterprise

Vadodara

Trusted Seller

Trusted Seller7 Years

Premium Seller

Premium SellerHex Head Bolt Diameter: 5Mm - 64Mm Millimeter (Mm)

Price Trend: 60-100 INR/Kilograms

MOQ500 Kilograms/Kilograms

Diameter5MM - 64MM Millimeter (mm)

Heat TreatmentTempered

Head TypeOther

Shree Ambey Metal Industries Limited

Ludhiana

Trusted Seller

Trusted Seller11 Years

Premium Seller

Premium SellerGalvanized Stainless Steel Hex Bolt

Price Trend: 300.00 - 700.00 INR/Piece

MOQ1000 Piece/Pieces

ColorSilver

Length50.8 - 127 Millimeter (mm)

Size2-5 Inch

WeightIndustrial

Product TypeHex Bolt

FinishGalvanized

Krishna Corporation

Palghar

Trusted Seller

Trusted Seller11 Years

Premium Seller

Premium SellerAaa Industries

Mumbai

Trusted Seller

Trusted Seller15 Years

Premium Seller

Premium SellerBig Sizes Hex Bolt

MOQ50 Piece/Pieces

Payment TermsCash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Ketan Industrial Works

Mumbai

Trusted Seller

Trusted Seller7 Years

Super Seller

Super SellerSS Hex Head Bolt

Price Trend: 1.00 - 5.00 INR/Piece

MOQ5000 Piece/Pieces

Supply Ability100000 Per Week

Delivery Time1 Week

Sample AvailableYes

Hexagonal Head Bolt DIN 933/931 Grade 8.8

Product DescriptionBeing the top names in Mumbai, Maharashtra, India. We are connected in manufacturing and supplying superb quality Hexagonal Head Bolt DIN 933/931 Grade 8.8. These Bolts are made implementing superb quality raw materials and are precisely engineered to suit the demands of our customers. We also perso

Payoma Industries

Mumbai

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerGrey Half Thread Hex Bolt

Price: 110 INR/Kilograms

MOQ100 Kilograms/Kilograms

Head TypeHexagon

ColorGrey

Product TypeHalf Thread Hex Bolt

SizeDifferent Size

UsageIndustrial

United Nut Bolt (india)

Ludhiana

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerCorrosion Resistant High Strength Full Threaded Stainless Steel 304 Hex Bolts

Price Trend: 1-50 INR/Piece

MOQ100 Number

Head TypeHexagon

SizeM2 TO M52

Product TypeSTAILESS STEEL 304 HEX BOLT

Length5 TO 300 Millimeter (mm)

StandardDIN 934

Rimco Overseas

Mumbai

Trusted Seller

Trusted Seller4 Years

Premium Seller

Premium SellerFull Thread Heavy Head Bolt

Price: 140 INR/Kilograms

MOQ1000 Kilograms/Kilograms

ColorSilver

SizeDifferent Size

UsageIndustrial

Product TypeFull Thread Heavy Head Bolt

Head TypeHexagon

Rnk Fasteners

Ludhiana

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerPolishing Industrial Hex Head Bolts

Price: 150 INR/Kilograms

MOQ1000 , Kilograms/Kilograms

Heat TreatmentTempered

UsageIndustrial

FinishPolishing

Varadhaman Trading Company

Ahmedabad

Trusted Seller

Trusted Seller4 Years

Premium Seller

Premium SellerRealiable Engineering

New Delhi

Trusted Seller

Trusted Seller7 Years

Super Seller

Super SellerBlack High Tensile Steel Hex Head Bolt

Price: 36 INR/Piece

MOQ1 Piece/Pieces

ColorBlack

UsageIndustrial

Product TypeCountry of Origin Made in India Size M 6 Color Siver Shape Hexagonal Surface Finish Polished and Ptfe Packaging Type Box and Gunny Bag Material Type SS

SizeDifferent Available

FinishAnodization

Methardware Engineering Private Limited

Ahmedabad

Trusted Seller

Trusted Seller5 Years

Super Seller

Super SellerMetal Hex Bolt - High Strength Steel, Durable Quality for Sugar and Oil Industries

Product DescriptionWe are offering Metal Hex Bolt to our consumers. These are used in diverse sectors of sugar industries, fertilizer plants, oil refineries and more. Our products are famous for their quality and longer life. These are available at a very low market rates

Swarna Fasteners

Delhi

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerBlack-Oxide Corrosion Resistant Black Forged Hex Head Bolt (Grade; 8.8 / 10.9 / Sa 193 Grade: B7)

Price: 165.96 INR/Carton

MOQ50 Number

ColorAuto Black

SizeM24 X 100mm

Length100 Millimeter (mm)

Head TypeHexagon

Product TypeHex Head Bolt

FinishBlack-Oxide

Polishing Corrosion Resistant Mild Steel Hex Bolt

Product TypeCorrosion Resistant Mild Steel Hex Bolt

Heat TreatmentTempered

Colorsilver

FinishPolishing, zinc Plating

Hex Head Bolt

Product DescriptionBeing a well-established company, we are involved in manufacture and supply a wide range of Hex Head Bolt in Ahmedabad, Gujarat, India. We manufacture these head bolts by using ultra-modern machinery utilizing high grade material and cutting-edge technology. Adding to that,, post manufacturing proce

Nikoo Forge Industries

Ahmedabad

Trusted Seller

Trusted Seller4 Years

Premium Seller

Premium SellerHex Head Bolt

Payment TermsCash on Delivery (COD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

Supply Ability20000 Per Month

Delivery Time1-4 Week

Zenith Industrial Products

Mumbai

Trusted Seller

Trusted Seller21 Years

Premium Seller

Premium SellerTorx Bolts - Color: As Per Requirement

MOQ100 Piece/Pieces

UsageIndustrial

SizeDifferent available

Heat TreatmentTempered

ColorAs Per Requirement

Head TypeHexagon

FinishPolishing

Daljit Engineering Works

Ludhiana

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerHex Bolt - MS and HT Materials, Golden Zinc Plated & Bright ZP Finish, Durable & Versatile Design

Product DescriptionWe are also supplying Hex bolts, screws for smaller DIA also at very competitive price in MS and HT also. Golden Zinc Plated, Bright ZP, HDG, If good qty then Rilson Blue also. These Hex Bolt are provided by us at very reasonable price

Hex Bolt - Metric Size M3-M36 | High-Quality Approved Range with Tested Durability

Payment TermsCheque, Letter of Credit (L/C), Telegraphic Transfer (T/T)

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

J. P. Engineers

Ahmedabad

Trusted Seller

Trusted Seller13 Years

Premium Seller

Premium SellerPolishing Ms Hex Bolts

Price: 78 INR/Number

MOQ100 Number

Heat TreatmentTempered

UsageIndustrial

SizeCustomized

FinishPolishing

StandardFirst Class

Latest From Hex Bolts

Hex Bolts

By:

Bharti Exports

Stainless Steel Hex Bolts

By:

Western Metal India

MS Long Head Hex Bolts

By:

Vrudhi Entp

Ready To Ship Hex Bolts

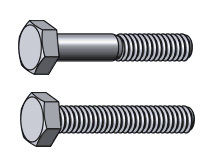

What are Hex Bolts?

Hex bolts are a type of threaded bolt that may be identified by the hexagonal form of their head, which has six sides. Both fully threaded and partially threaded hex bolts, with the clear shank across the entire body, have many uses and are widely employed in building and related industries.

You can pick the bolt that is most appropriate for the task at hand because there is such a wide range of options in terms of kind, material, size, and finish.

Due to the unique head form, hex bolts are also frequently referred to as hexagon bolts. Another name for hex bolts is hex head bolts. Hex head bolts are extremely flexible and adaptable fasteners, which enables them to be used for a wide variety of purposes across a wide variety of industries and applications.

Hex head screws for wood and metal, amongst many other materials and situations, are only one example of a common application for hex bolts.

They have excellent tensile qualities, and the majority of conventional types are versatile enough to be employed in a variety of settings depending upon the material and finish. As a direct consequence of this, hex bolts are one of the most common types of staple fasteners.

Where are Hex Bolts Used?

Here are some common uses of Hex bolts.

1. Construction Projects

Hex bolts are utilised in the construction industry for a variety of purposes, the most common of which is to establish joints between structural parts or to insert elements into a surface or substance.

Hex bolts are sometimes intended to be a permanent component of a building or other structure. This means that once they have been installed, they cannot be moved and do not require any additional maintenance or replacement.

2. Buildings, Bridge and Roads

Hex bolts are frequently utilised for projects involving wood, metal, and other types of construction materials. Examples of such projects include bridges, docks, buildings, and highway infrastructure.

They have excellent tensile qualities and can be utilised in a number of different contexts Hex bolts are put to use for applications that require heavy-duty fastening and fixing the majority of the time.

3. Machinery Assemblies

They are used to join two pieces of material together. However, unlike hex bolts, machine bolts do not have a chamfered point, nor are they built with a washer-bearing surface on the underside of the head of the bolt.

They normally come with options for both a hex head and a square head, but you can get them in either shape.

4. Woodworking

Recommended for structural connecting, including framing walls, due to their greater flexibility under pressure, in contrast to screws, which can snap under pressure.

In addition to this, you will need their assistance while installing hardwood flooring, fastening siding and roofing, and securing plywood sheathing used for the outside walls.

5. Engineering

In most cases, hex bolts are utilised for the purpose of either positioning or holding materials or items together. The bolt is easier to put into nuts and holes thanks to the chamfer that is located on the other end of the head. This chamfer gives a slightly bevelled edge.

6. Vehicle and Automotive

The nuts and hex bolts are utilised in a variety of applications, including holding engine components, suspension arms, and dashboards in place. They are straightforward but indispensable, and millions of them are manufactured every day using a variety of iron and aluminium alloys.

How are Hex Bolts Manufactured?

The method of manufacturing

1. Cold Forging

The first step in cold forging involves taking massive steel wire rods, uncoiling them, and cutting them to the desired length.

The grade of steel used in manufacturing is standardised across the sector After that, the wire is cold-forged into the desired shape by utilising specialised apparatus. In this process, the steel is shaped while it is still at room temperature by passing it through a sequence of dies while the pressure is turned up to a very high level.

The tooling itself can be fairly complicated, with as many as 200 separate parts and tolerances that are measured in hundredths of a millimetre. As soon as it is developed, cold forging will ensure that bolts can be manufactured rapidly, in huge volumes, and with a high degree of consistency.

For more intricate bolt designs, which cannot be curved through cold forging alone, some additional turning or drilling may be required. This is because cold forging does not allow for the formation of rounded corners.

Turning requires spinning the bolt at a high speed while steel is sliced away to obtain the desired form and design.

Turning is also known as lathing. Drilling is a technique that can be utilised to create holes all the way through the bolt. At this point in the procedure, washers may be affixed to certain bolts in order to fulfil any prerequisites that may be necessary.

2. Heat Treatment

The act of subjecting a bolt to high temperatures in order to make the steel more resistant to wear and tear is known as heat treatment.

This technique is normal for all bolts. Typically, threading is accomplished before heat treatment, either by rolling or cutting the steel when it is in a more malleable state.

The process of rolling is quite similar to that of cold forging it entails passing the bolt through a die in order to form and shape the steel into threads. The process of cutting involves cutting and removing steel in order to make threads.

Because subjecting steel to heat treatment will cause it to undergo a transformation that will make it tougher, it is preferable and more economical to apply threading before subjecting the steel to heat treatment. Threading, on the other hand, should be done after heat treatment in order to achieve superior fatigue performance.

The heat treatment can leave the bolt with heat markings and even cause some small damage to it. "Because of this, certain customers require threading to be completed following heat treatment. This is especially true for applications involving engine and cylinder head bolts.

Because it requires the formation of hardened steel, the process is more expensive, but the threads will be able to keep their shape for a longer period of time.

3. Thread Rolling

After that, one of three distinct methods is utilised to cut the clear. During the subsequent pass, two level bites are used to cut the hex bolts. One of the dust bites is fixed, another one moves in a responsive manner, and the transparent screw is moved in between the two.

In order to construct the final string, the hex bolts clear to be replaced between several round passes while using a center tube shaped kick the bucket.

This is done so that the kick of the bucket may function properly. The inertial force imparted by a planet's rotation Last but not least, the string can be moved using the bucket cycle. It maintains a fixed position on the screw clear, allowing a few dust-cutting machines to move freely around the clear.

4. Size

The heat treatment has the potential to have the effect of causing the steel to revert to the round shape of the original steel wire when it is applied to long bolts with a length that is more than ten times the diameter of the bolt. As a result, the application of a technique that straightens is frequently required.

5. Surface

The application of the bolt and the specifications of the customer are what guide the selection of the surface treatment. When it comes to fasteners, corrosion resistance is frequently the primary issue as a result, a zinc-plated coating that is applied by means of electrolytic treatment is a typical solution.

During this step of the process, the bolt is first immersed in a liquid that contains zinc, and then an electric current is passed through the liquid and the bolt in order to coat the bolt with zinc.

However, there is a higher chance of hydrogen embrittlement when the treatment is performed electrolytically.

Zinc flakes are yet another choice; despite their increased cost, they provide an even higher level of protection against corrosion.

Phosphate is a more cost-effective choice than other alternatives in situations where corrosion resistance is not a primary concern, such as inside an engine or in an application that is frequently subjected to oil.

After the application of the surface treatment, standard bolts are normally in a state where they are ready to be packaged. However, more complex designs may require additional assembly in the form of brackets or other components.

Patching will be necessary for the other bolts as well, either in the form of a locking patch or a liquid patch. A locking patch is constructed by layering a substantial amount of nylon over the threads in order to enhance grip. The thread-forming torque can be improved with the application of a liquid patch.

Features Of Hex Bolts

The feature of the hex bolt is to supply a clamp load, also known as a preload, in order to adequately compress and stress the gasket, as well as to withstand the separating forces that are caused by the hydrostatic end force and any other external stresses.

The pressure of the internal fluid exerted across the internal area of the flange contributes to the generation of the hydrostatic end force. In most cases, the internal area is equal to the diameter of the interior of the sealing element.

Every Hex bolt has the characteristics of a hefty spring. When you tighten the nut against the flange, the bolt lengthens, while the flange and the gasket are squeezed together.

There is no way of bolt-tightening that does not result in the bolt being stretched. In order to stretch the bolt, the torque-tightening method makes use of the thread helix created by twisting the nut in opposition to the reactive forces of the flange.

In order to achieve an axial stretch using the hydraulic hex bolt-tensioning method, an annular piston that is threaded on the end of the hex bolt is utilised. In the section titled "Methods of hex bolt Tightening," topics such as hydraulic bolt tensioning and torque tightening are explored. In the region of their elastic properties, hex bolts stretch in accordance with Hooke's law.

FAQs: Hex Bolt

Q. Top Manufacturers and Suppliers of Hex Bolts in India

Ans. India's top manufacturers and suppliers of Hex Bolts are Inconel Fasteners, Monel Fasteners, Hastelloy Fasteners, and Silicon Bronze Fasteners.

Q. How to Find Right Hex Bolts?

Ans. Check it carefully to make sure you have the right hex bolt length, thread size, and thread pitch.

Q. What is the purpose of a hex bolt?

Ans. Hex bolt is a kind of fastener which is used in different application areas. This is used for both wood and metal surface. It is used in combination with a hex nut.

Q. What does hex stand for in hex bolt?

Ans. Hex is shortened form of hexagonal which means six-sided. The head of hex bolts has six flat sides for offering a better wrenching experience that is why it is called hex bolt.

Q. What is the best place to buy hex bolts?

Ans. Hex bolts can be bought from trusted B2B online marketplaces. Such marketplaces list several manufacturers and suppliers who deal in all kinds of hex bolts in many different materials.

Q. How can I find a hex bolt supplier near me?

Ans. Finding a hex bolt manufacturer or supplier near you is very simple. You can simply type ‘hex bolt supplier near me’ on a search engine and get a list of suppliers near your locality.

Q. Are hex bolts resistant to corrosion?

Ans. Most of the hex bolts are made with corrosion-resistant materials, such as stainless steel, alloy steel, copper, aluminium and others.

Related Topic:

Top 10 Hex Bolts Manufacturers, Suppliers & Exporters in India

Manufacturers & Suppliers of Hex Bolts

Company Name | Member Since |

|---|---|

Zenith Industrial Products Mumbai, India | 21 Years |

Aaa Industries Mumbai, India | 15 Years |

Technogrip Products Ludhiana, India | 14 Years |

J. P. Engineers Ahmedabad, India | 13 Years |

Ibk Engineers Pvt. Ltd. Bengaluru, India | 11 Years |

Shree Ambey Metal Industries Limited Ludhiana, India | 11 Years |

Krishna Corporation Palghar, India | 11 Years |

Rahul Fasteners & Fittings Pune, India | 11 Years |

Vinay Engineering Company Vasai, India | 8 Years |

Nandika Fasteners New Delhi, India | 7 Years |

Popular Products