Paper, Paper Converting Machinery

(3868 products)Product Showcase

High Insulation Four Colour Flexo Printing Machine

By:

Mohindra Mechanical Works

Rotogravure Printing Press Machine Capacity: 10000 Per Hour

By:

Mohindra Mechanical Works

220 V Single Phase Flaps Folding Taping Machines

Price: 375000 INR/Unit

MOQ1 Unit/Units

GradeSemi-Automatic

ColorBlue

Cutting Speed20 m/m

Weight (kg)325 Kilograms (kg)

Join Pack Machines (pvt.) Ltd.

Delhi

Trusted Seller

Trusted Seller10 Years

Super Seller

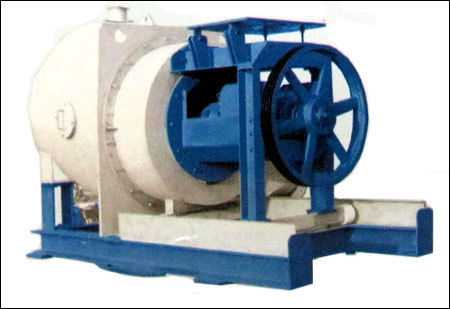

Super SellerBlue Biomass Wood Saw Dust Pallet Making Machine

Price: 130000 INR/Piece

MOQ1 Piece/Pieces

GradeSemi-Automatic

ColorBlue

TypePulping Machine

MaterialSS

ComputerizedYes

Control SystemPLC Control

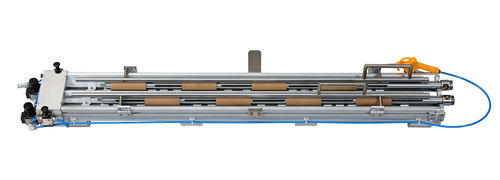

Paper Core Loading Machine Grade: Automatic

Price Trend: 1500.00 - 1800.00 USD ($)/Set

MOQ1 Set/Sets

GradeAutomatic

TypeOther

ConditionNew

MaterialStainless Steel

Voltage220-440 Volt (v)

Warranty1 Year

Xiamen Delish Automation Equipment Co. Ltd.

Xiamen

Automatic High Consistency Paper Pulper Machine

Price: 2000000 INR/Set

MOQ1 Set/Sets

ColorOther

MaterialStainless steel

FeatureHeavy Duty Machine, Durable, Rust Proof, Highly Efficient, Less Power Consumable, Other

ComputerizedYes

Automatic GradeAutomatic

Control SystemPLC Control

Labh Projects Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller5 Years

Super Seller

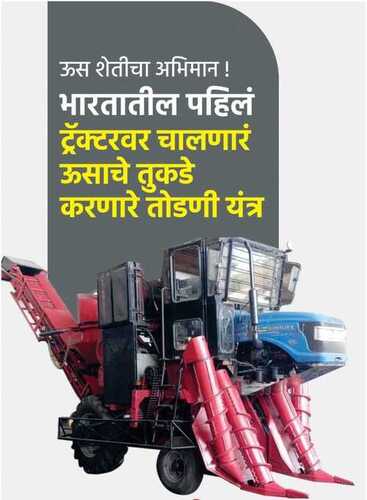

Super SellerSugarcane Harvester

Price: 500000 INR/Number

MOQ1 Number

Supply Ability1 Per Day

Delivery Time5 Days

Hanje Hydrotech

Pune

Trusted Seller

Trusted Seller15 Years

Premium Seller

Premium SellerIndustrial Baling Press Machine - New Condition | Efficient Industrial Usage, Advanced Baling Press Technology

Price: 2200000.0 INR/Unit

MOQ1 Unit/Units

Product TypeBaling Presses Machine

UsageIndustrial

ConditionNew

Paper Cutter Machine - High-Quality Steel Body, Cutting Capacity 40mm Thick Sheets | Precision Sharp Cutters, Optional A4/A3 Size

Product DescriptionWe manufacture, export and supply Paper Cutter Machine to our customers in Delhi, India. Our Paper Cutter Machine has high quality steel body, plastic handle Cutting capacity: 40mm thick' sheets. These are well designed & highly precision & sharp cutter 2 specifications optional: A4 and A3 Well pa

Gb Tech (india)

Delhi

Trusted Seller

Trusted Seller19 Years

Super Seller

Super SellerIndustrial 2 Ton Load Capacity Semi Electric Paper Roll Stacker

Price: 380000 INR/Unit

MOQ1 Unit/Units

GradeSemi-Automatic

ColorMultiple

TypeOther, Paper Roll Stacker

MaterialMild Steel

Capacity2 T/hr

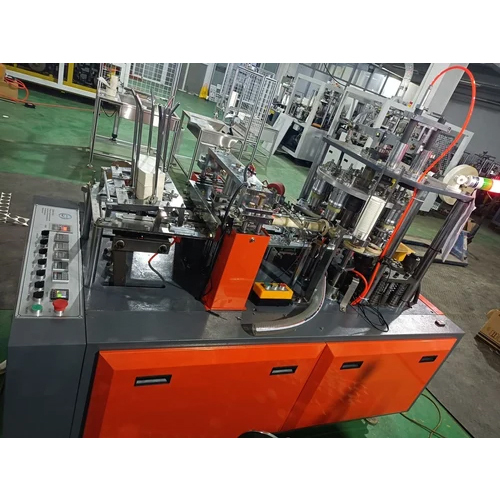

High Speed Paper Cup Making Machine Capacity: 40-50 Pcs/Min

Price: 770000.00 INR/Unit

MOQ1 Unit/Units

GradeAutomatic

MaterialPaper

Capacity40-50 Pcs/min

ComputerizedNo

Control SystemPLC Control

Weight (kg)2200 Kilograms (kg)

Jai Durge Industries

Jaipur

Trusted Seller

Trusted Seller9 Years

Premium Seller

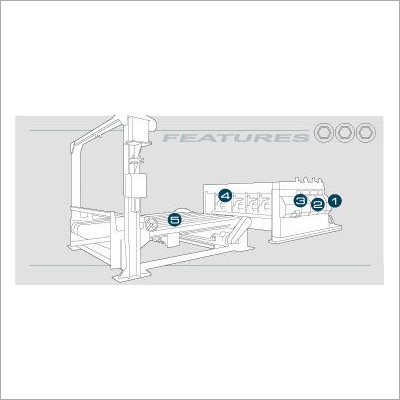

Premium SellerAutomatic Flexo Printer Slotter Cutting Speed: 180 Sheets/ Min M/M

MOQ1 Set/Sets

Cutting Speed180 sheets/ min m/m

Power44.6 kw for 3 color Watt (w)

Weight (kg)25300 Kilograms (kg)

Dimension (L*W*H)14340 x 4850 x 3270 Millimeter (mm)

Tymi Machinery Industry Co. Limited

Taipei

Trusted Seller

Trusted Seller8 Years

Super Seller

Super SellerRipple Making Machine For Paper Cup Cutting Speed: 30-60 M/M

Price: 3000000 INR/Set

MOQ1 Set/Sets

GradeSemi-Automatic

TypeOther

ComputerizedNo

Cutting Speed30-60 m/m

Voltage380-440 Volt (v)

Power50 Horsepower (HP)

Senior Paper Packing Machinery Mfg. Co.

Amritsar

Trusted Seller

Trusted Seller20 Years

Super Seller

Super SellerMetal Automatic Paper Bag Making Machine

Price Trend: 750000.00 - 900000.00 INR/Piece

MOQ1 Piece/Pieces

GradeAutomatic

TypePaper Bag Making Machine, Other

MaterialMetal

Control SystemPLC Control

Voltage240-420 Volt (v)

ColorWhite

Feather Touch Tissues

Coimbatore

Trusted Seller

Trusted Seller7 Years

Super Seller

Super SellerKnowzzlejet Digital Web Press - Color: White

Price: 30000000.0 INR/Unit

MOQ1 Unit/Units

GradeAutomatic

ComputerizedNo

Control SystemHuman Machine Interface

ColorWhite

Warranty1 Year

Pressline India Pvt. Ltd.

New Delhi

Trusted Seller

Trusted Seller4 Years

Super Seller

Super SellerFully Automatic Paper Cup Making Machine - Material: Ms

Price: 550000.0 INR/Unit

MOQ1 Unit/Units

TypeOther

MaterialMS

Control SystemPLC Control

Voltage220 to 415 Volt (v)

PowerSingle Phase to 3 Phase Watt (w)

Warranty2 Year

Machine World

Kolkata

Trusted Seller

Trusted Seller7 Years

Premium Seller

Premium SellerCustomized Abrasive Roll Slitter Machine

Price: 5000 USD ($)/Set

MOQ1 Set/Sets

ComputerizedYes

Control SystemPLC Control

Cutting Speed5-10 m/m

Cutting Size100-1700mm

Cutting Thickness0.5 Millimeter (mm)

Weight (kg)1800 Kilograms (kg)

Isharp Abrasives Tools Science Institute

Zhengzhou

Trusted Seller

Trusted Seller11 Years

Premium Seller

Premium SellerIndustrial Slitter Rewinder Machine - Color: White

Price: 10000 USD ($)/Piece

MOQ1 Piece/Pieces

GradeSemi-Automatic

TypeSlitting Rewinder

MaterialMild Steel

ComputerizedNo

Voltage220 Volt (v)

ColorWhite

Havesino Slitter

Hangzhou

Trusted Seller

Trusted Seller5 Years

Super Seller

Super SellerPaper Cutting Machine

Price Trend: 640000.00 - 750000.00 INR/Piece

MOQ1 , Piece/Pieces

Supply Ability50 Per Month

Delivery Time1 Week

Khalsa Engineering Works

Delhi

Trusted Seller

Trusted Seller12 Years

Super Seller

Super SellerPaper Board Making Machine Capacity: 200 Ton/Day

Price: 390000000 INR/Unit

MOQ1 Unit/Units

GradeAutomatic

ColorYellow & Green

TypeOther, Paper Board Making Machine

MaterialSS and MS

Capacity200 Ton/day

ComputerizedNo

Rajshree India

Ahmedabad

Super Seller

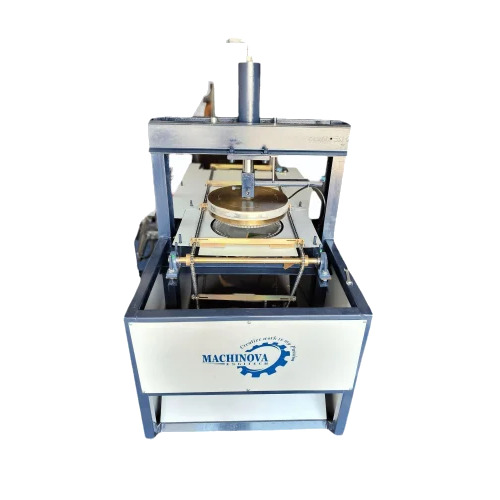

Super SellerSilver Paper Dish Making Die

Price Trend: 1500.00 - 2000.00 INR/Unit

MOQ1 Unit/Units

MaterialSS

ComputerizedNo

Control SystemHuman Machine Interface

Cutting Size7, 8, 9, 10.5, 11 inch

Voltage220 Volt (v)

Weight (kg)10 Kilograms (kg)

Greentech Engineering

Surat

Trusted Seller

Trusted Seller7 Years

Super Seller

Super SellerStk 113 Battery Operated Paper Roll Stacker, Usage/Application: Industrial

Product DescriptionStk 113 Battery Operated Paper Roll Stacker

Lift Mech Industries

Ahmedabad

Trusted Seller

Trusted Seller6 Years

Super Seller

Super SellerHigh Speed Paper Container Machine Grade: Automatic

Price: 1100000 INR/Unit

MOQ1 Unit/Units

GradeAutomatic

TypeHigh Speed Paper Container Machine, Other

MaterialMetal

Control SystemHuman Machine Interface

Voltage440 Volt (v)

Weight (kg)2000-3000 Kilograms (kg)

Grey Paper Embossing Machine Grade: Automatic

Price: 650000 INR/Unit

MOQ1 Unit/Units

ColorGrey

GradeAutomatic

TypePaper Embossing Machine

MaterialMild Steel

ComputerizedNo

Voltage220-440 Volt (v)

Krishna Fab Tech

Surat

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerPaper Plate Circle Cutting Machine - Grade: Automatic

MOQ1 Unit/Units

GradeAutomatic

MaterialMetal

Control SystemHuman Machine Interface

Voltage220-230 Volt (v)

WarrantyYes

Shivansh Engineering

Pune

Trusted Seller

Trusted Seller1 Years

Premium Seller

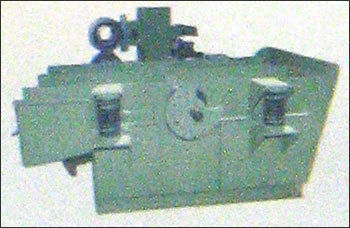

Premium SellerDouble Box Double Cylinder Waste Paper Baling Press Machine - Capacity: 50 Ton/Day

Price: 580000 INR/Unit

MOQ1 Unit/Units,

ColorBlue

GradeAutomatic

TypeOther, Double Box Double Cylinder Waste Paper Baling Machine

MaterialMild Steel

Capacity50 Ton/day

ComputerizedNo

Shree Rameshwar Eng. Works

Ahmedabad

Trusted Seller

Trusted Seller4 Years

Premium Seller

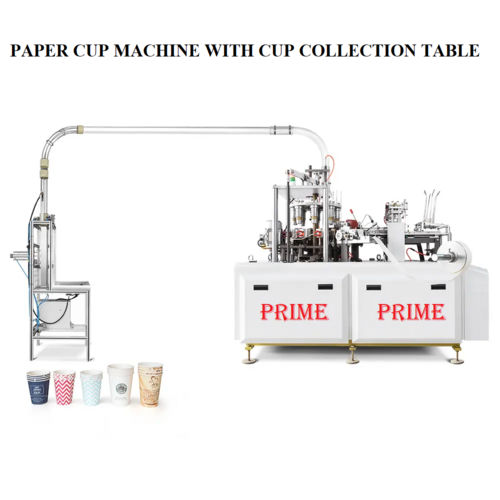

Premium SellerHigh Speed Ultrasonic Paper Cup Making Machine Capacity: 50-70 Pcs/Min

Price: 5200000 INR/Number

MOQ1 Piece/Pieces

GradeAutomatic

Capacity50-70 Pcs/min

Control SystemPLC Control

Voltage220 Volt (v)

Weight (kg)1500 Kilograms (kg)

Warranty1 Year

Prime Machinery

Delhi

Trusted Seller

Trusted Seller4 Years

Premium Seller

Premium SellerBlue Hydraulic Paper Plate Machine

Price: 64000 INR/Unit

MOQ1 Unit/Units

ColorBlue

GradeSemi-Automatic

MaterialStainless Steel

ComputerizedNo

Voltage220-440 Volt (v)

WarrantyYes

Vinpat Machinery (opc) Private Limited

Lucknow

Trusted Seller

Trusted Seller5 Years

Premium Seller

Premium SellerHand Press Paper Plate Making Machine - Grade: Semi-Automatic

Price: 100000 INR/Unit

MOQ1 Unit/Units

GradeSemi-Automatic

MaterialStainless Steel

ComputerizedNo

Control SystemFrequency Speed Control

Voltage220 Volt (v)

WarrantyYes

Shri Balaji Machinery

Delhi

Trusted Seller

Trusted Seller2 Years

Super Seller

Super SellerSingle Die Paper Plate Making Machine Grade: Automatic

Price Trend: 45000.00 - 200000.00 INR/Unit

MOQ1 Unit/Units

GradeAutomatic

TypeOther, Paper Plate Making Machine

MaterialMetal

Voltage240 Volt (v)

Bilal Engineering Works

Ghaziabad

Trusted Seller

Trusted Seller4 Years

Premium Seller

Premium SellerLatest From Paper, Paper Converting Machinery

Dumping Screen (Paper, Paper Converting Machinery)

By:

Saurashtra Specialities Pvt. Ltd.

Paper Mill

By:

Fluidics

Coated Duplex Board Machines

By:

Wemet Papers India Pvt. Ltd.

Vibrating Screen

By:

Ambica Paper Machineries

Globe Winders

By:

The Globe Radio Company

Explore More Cities

Ready To Ship Paper, Paper Converting Machinery

The Best Guide For Paper, Paper Converting Machinery

Paper conversion describes the procedures that are carried out to transform unprocessed paper into finished goods. You can get this raw material in either sheets or rolls. Books, packaging, newspapers, labels, and so on are just a few examples of these final items' widespread use. Fascinatingly, you'd find out that bearings are usually used in the machinery used for paper converting and printing activities to ensure accurate, precise, and smooth operation.

The global market for paper converting machines is forecast to grow from its current valuation of $41.4 billion in 2020 to a projected $49.7 billion in 2027, a compound annual growth rate (CAGR) of 2.7%.

Raw materials are the first step in the paper conversion process, which ultimately results in a completed product. The procedure involves the steps listed below.

- The process of gathering raw fibers and transforming it into pulp

- Transformation of wet pulp into a finished paper roll via straining, bleaching, flattening, and drying

- Creating smaller, more manageable pieces from the master paper roll

- Modifying the smaller rolls to the desired dimensions and shape

A paper converter is a machine that transforms one type of paper into another. For instance, a restaurant may have a large roll of kraft paper printed and coated, and sheeted to their exact specifications to use as sandwich wrappers.

Benefits of Paper Conversion

1. Become Eco-Friendly

If you care about the environment, you should use as little paper as possible. Simply by digitizing your archived files, you may cut your paper consumption and set an example for the future. You may help make the world a more sustainable place by taking part in paper document conversion.

2. Improve Recording Keeping

Files, whether they contain tax data, personal details, or business activities, should always be secure and simple to access. By going digital, you can make sure that everything is properly organized and easily retrievable. When compared to digging through piles of paper, files, and cupboards, this method of record-keeping is a huge improvement.

3. Protect documents

Your paper records are never completely safe in storage since accidents like fires, floods, and insect infestations can happen anywhere, at any time. However, you need not worry about the safety of your documents at all if you get them scanned and converted to digital files.

4. Free up Storage

With the availability of paper document conversion technologies, there is no longer any need to fill up a spare bedroom or closet with boxes of paper records. The extra space in your house or business could be used to store things like furniture or electronics. When you get all of your paper records digitized, you'll immediately notice a reduction in the amount of clutter in your workspace or living quarters.

5. Improve Environmental Footprint

There has been substantial progress in the business sector to lessen its negative impact on the environment. It has developed techniques for recycling used paper into new materials and goods, which has helped cut down on the number of fossil fuels required for paper product manufacture. The latter is critical in the effort to shrink landfills.

6. Effective for Product or Packaging

Paper is employed in numerous everyday items. Books, newspapers, bags, and magazines are staples in the retail industry. Though most manufacturing and retail establishments package their wares in some type of paper (e.g., boxes, cartons, packing paper, etc.), this is not always the case.

Common Paper Converting Processes

1. Virgin Timber

Softwood trees like spruce, pine, fir, larch, and hemlock, and hardwood trees like eucalyptus, popular, aspen, and birch are used to make wood pulp.

2. Raw materials to Paper Mill

Wood pulp and recycled Paper, Paper Converting Machinery pulp are delivered to the paper mill just before the paper is made.

3. At the mill

- The pulp is slurped up after being cleansed, refined, and cleaned.

- Colorants, finishes, and additives are blended in.

- The paper web has had most of its water evaporated.

- The paper web is dried by passing it through a series of heated rollers.

4. Roll Slitting

Here, the paper begins as wide master rolls. If you need a narrower roll, say for kraft paper table coverings, a paper conversion may precisely slit it down to size.

5. Sheeting

A sheeter is someone who unwinds paper from a roll and cuts it into individual sheets. Custom paper sheets can be made to your exact specifications; all you need to do is decide on the size you need.

6. Flexographic printing

Disposable cups and envelopes, food wrappers, folding cartons, candy, containers and paper bags, and corrugated containers are commonly printed using this technology. On top of that, flexo printing is often an integral aspect of custom projects for clients searching for innovative paper solutions.

7. Coating

As a result of this paper coating process, a common paper product is transformed into a form better suited to a specific use. Tags and labels, specialty tapes, and water- and grease-resistant papers for the food industry are just some of the products that require coating.

8. Laminating

This method, like coating, can transform regular paper into something extraordinary. Paper laminating is a viable option if you need metalized paper for gift wraps, POP displays, or decorative packaging.

Types of Paper Converting Machinery

1. Bagging Machines

Packaging equipment for making paper bags. These may be single 'carrying bags,' sandwich bags on rolls, or, for more complex tasks, garbage bags on rollers, with a drawstring closure placed at one end of each bag.

2. Coating Machines

Coating machines use a process that guarantees a uniformly complete application of a liquid or gaseous coating to a substance on either one or both sides of a rotating web. Acquiring the precision of machine speed is important, as are balance and synchronization between the various parts of the machine. Drying time is required for many coatings, including those that are adhesive, silicone, anti-fog, anti-static, and UV resistant.

3. Stamping Machines

Hot foil stamping on paper or non-woven material, as well as die-cutting, are two of the many applications for modern stamping machines' high levels of automation and precision. Bottles, paper cups, paper plates, jars, and other containers can all be labeled with the help of a stamping machine.

4. Embossing Machines

Tissues, kitchen towels, and napkins benefit from embossing because the ornamental holes punched into the paper boost its ability to absorb water and soften the material.

5. Paper Sheeters

Machines called "paper sheeters" are used to reduce the size of paper sheets to a given dimension. They are very precise and deliver perfectly uniform paper stacks for subsequent processing or distribution.

6. Slitters/ Rewinders

There are two distinct kinds of slitters; roll saw slitters and rewind slitters. The rewinding slitter unwinds the material from one roll, cuts it to the specified length, and then rewinds it onto the second roll. The roll is cut into multiple sections by a slicer called a "roll saw machine."

Even though it lacks the capacity to rewind onto new cores, the razor roll saw can cut through a roll four times as fast as a rewinder.

7. Lamination Machines

One or both sides of a document can be laminated with the help of a laminator machine.

There are many widely used lamination systems on the market, including:

- Pressurized cold systems are used to damage the film.

- Laminating graphics and signs is a breeze with a single hot system since the heat eliminates the risk of "silvering" on the printed surface.

- Two-stage heating systems can laminate & enclose.

8. Carton Folding Sheeter and Paper Sheeter

As a result of the paper and folding carton sheeter's versatility and fast speed, you are able to efficiently create large numbers of sheets in precise sizes for precise production runs, thereby maximizing efficiency and decreasing waste. This also paves the way for them to bypass the middlemen and acquire paperboard straight from the manufacturers, saving money.

9. Roll Winding Machine

The roll winding machine has various applications. These machines are offered to buyers in a wide range of configurations and can be tailored to suit individual needs.

FAQs: Paper, Paper Converting Machinery

Q. What techniques are used in paper converting machinery?

Ans. Here are the top effective techniques used in paper converting machinery

- Slitting

- Rewinding

- Roll Sawing

- Coating

- Flexographic Printing

- Sheeting

- Laminating

Q. How much does a paper converting machine cost?

Ans. The cost of a paper converting machine is between Rs 1 lakhs to 10 lakhs in India.

Q. Which is the largest paper converting machine company?

Ans. PCMC is one of the biggest Papers converting Machine companies in the US, Belgium, and Italy. The company guarantees excellent customer service and prompt repairs for all of the machinery you purchase from them.

Q. Where can I purchase Paper Converting Machine in India?

Ans. Tradeindia is the biggest platform to purchase affordable paper converting machines in India. You can get machines from Rs 1 lakhs to 5 lakhs here.

Manufacturers & Suppliers of Paper, Paper Converting Machinery

Company Name | Member Since |

|---|---|

Senior Paper Packing Machinery Mfg. Co. Amritsar, India | 20 Years |

Gb Tech (India) Delhi, India | 19 Years |

Hanje Hydrotech Pune, India | 15 Years |

Xiamen Delish Automation Equipment Co. Ltd. Xiamen, China | 13 Years |

Khalsa Engineering Works Delhi, India | 12 Years |

Isharp Abrasives Tools Science Institute Zhengzhou, China | 11 Years |

Join Pack Machines (Pvt.) Ltd. Delhi, India | 10 Years |

Jai Durge Industries Jaipur, India | 9 Years |

Tymi Machinery Industry Co. Limited Taipei, Taiwan | 8 Years |

Rajshree India Ahmedabad, India | 8 Years |

Popular Products