- Tradeindia

- Brick Making Machine

- Fly Ash Brick Making Machine

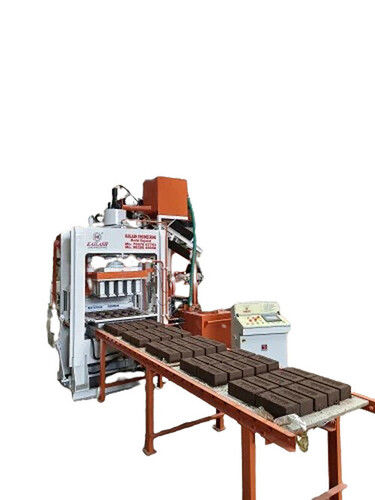

Fly Ash Brick Making Machine

(710 products)Fly Ash Brick Making Machine Industrial

1650000 INR/Piece

MOQ1 Piece/Pieces

Product TypeFly Ash Brick Making Machine

General UseIndustrial

MaterialOther, Metal

AutomaticYes

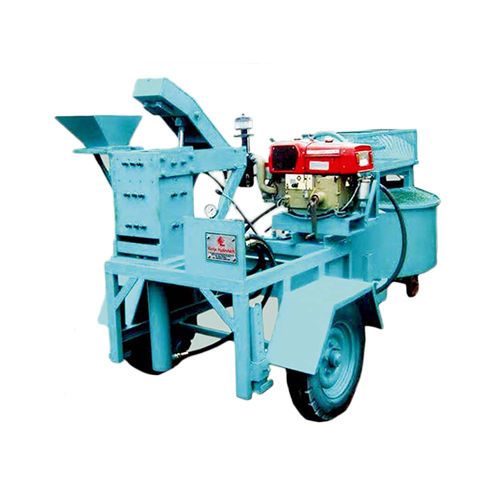

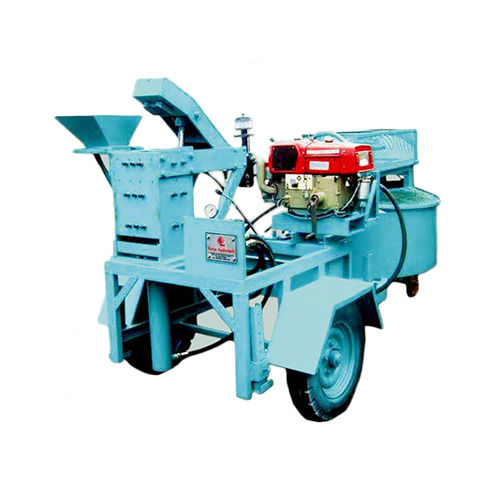

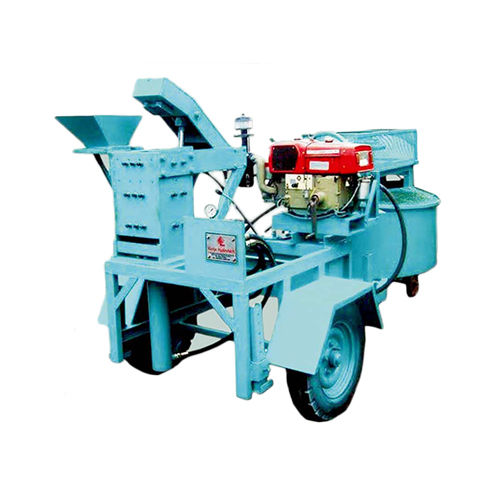

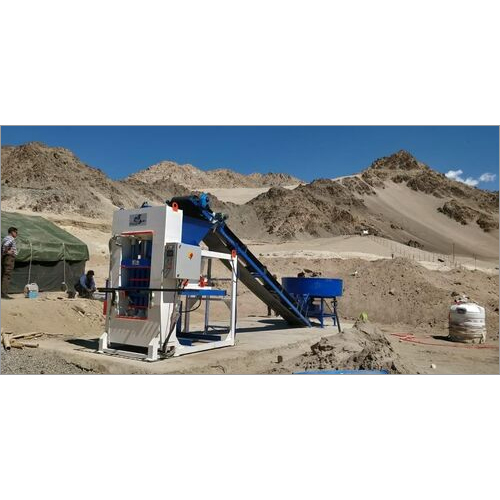

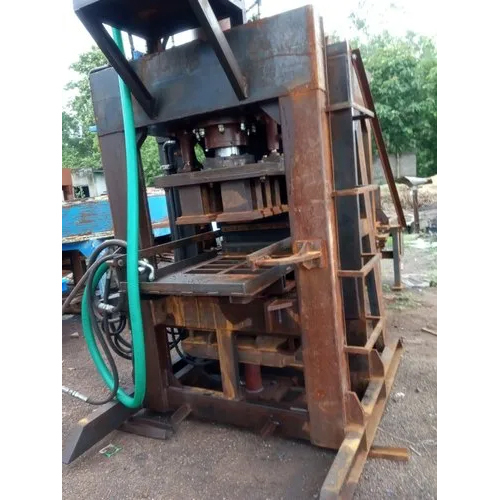

High Durability Fly Ash Brick Making Machine By Hanje Hydrotech

290000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

ComputerizedNo

AutomaticYes

FeatureHigh Durability

WarrantyYes

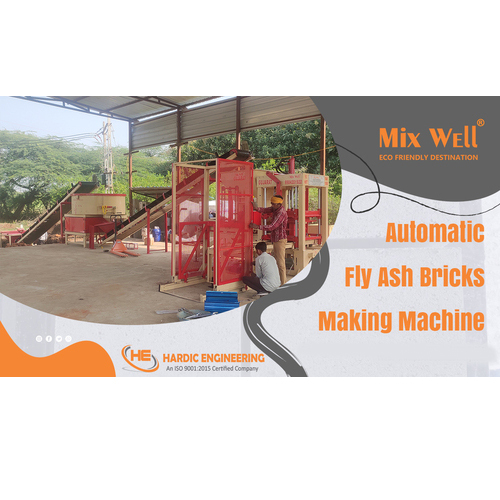

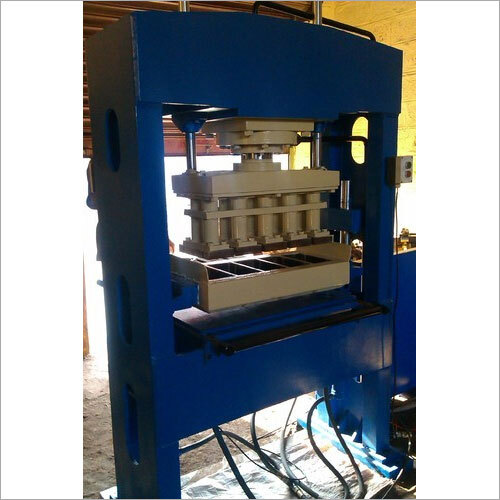

Automatic Fly Ash Brick Making Machine

1280000 INR/Unit

MOQ1 Unit/Units

MaterialFly Ash

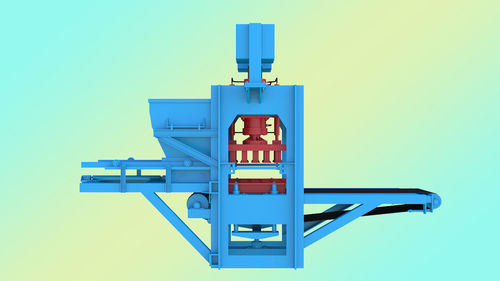

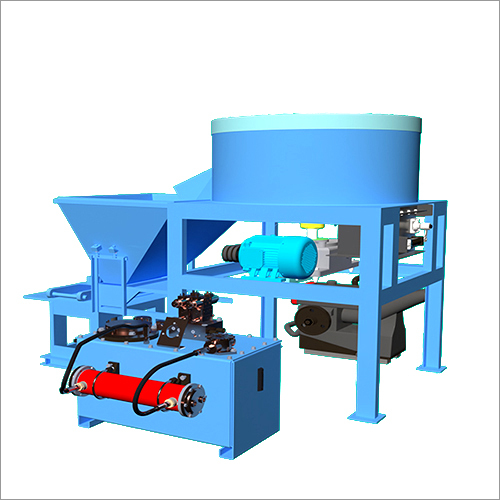

Blue Brick Making Machine

60000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypeBrick Making Machine

General UseIndustrial

MaterialStone

TypeAAC Plant

ComputerizedNo

Fly Ash Brick Plant - Durable Design for Sustainable Brick Production | Energy-Efficient, Environmentally Friendly Manufacturing Process

Price: 3200000 INR/Unit

MOQ1 Unit/Units,

General UseIndustrial

MaterialFly Ash

ComputerizedNo

AutomaticOther, Automatic

PLC ControlYes

MethodHydraulic Pressure

Brick Making Machines - Color: Blue

Price: 1700000 INR/Piece

MOQ1 Set/Sets

ColorBlue

Product TypeBrick Making Machine

MaterialFly Ash

ComputerizedYes

AutomaticYes

PLC ControlYes

Laxmi Engineering Works

Ahmedabad

Trusted Seller

Trusted Seller11 Years

Super Premium

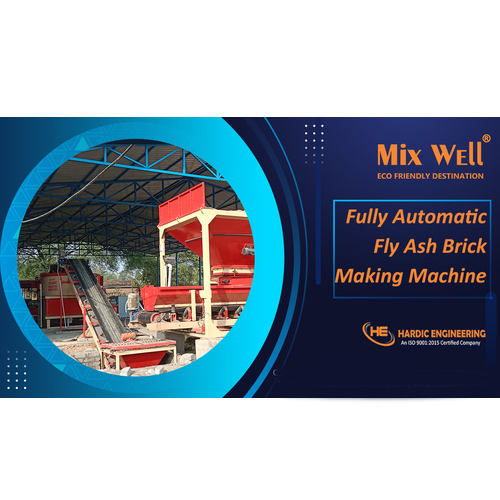

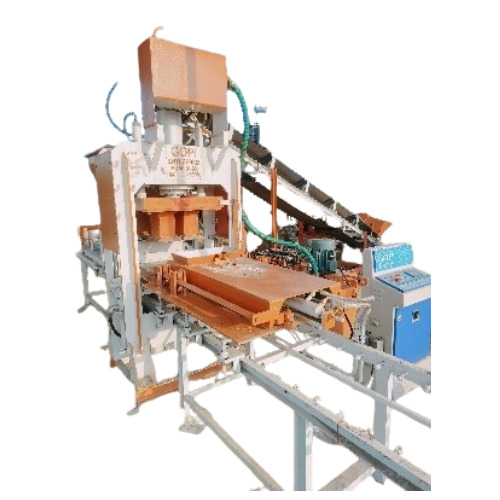

Super PremiumFully Automatic Fly Ash Brick Making Machine - Metal Build, High Durability | Industrial Use, Fully Automatic Operation

Price: 1100000 INR/Unit

MOQ1 Unit/Units,

Product TypeFly Ash Brick Making Machine

General UseIndustrial

MaterialOther, Metal

AutomaticYes

FeatureHigh Durability

Akshar Precast Industries

Ahmedabad

Trusted Seller

Trusted Seller4 Years

Super Seller

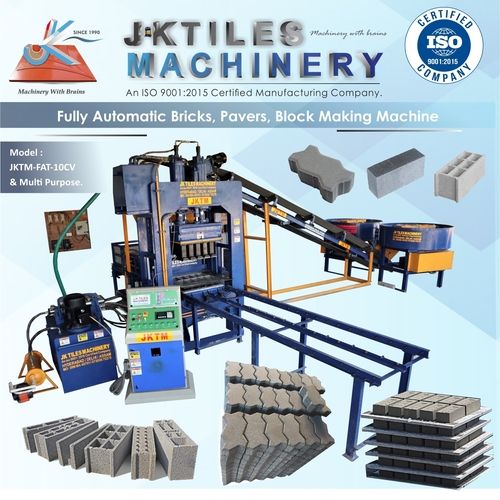

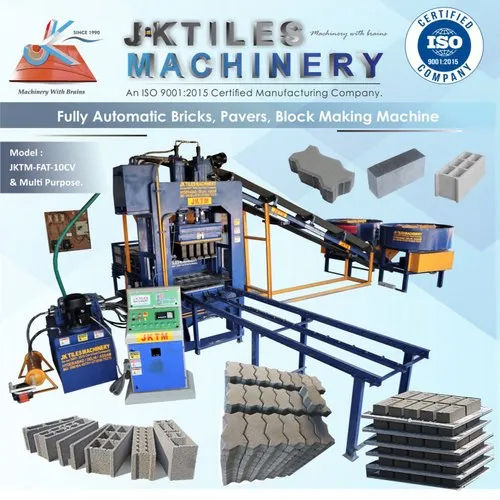

Super SellerFly Ash Brick Making Machine

Price: 2200000 INR/Piece

MOQ1 Piece/Pieces

Product DescriptionJ. K. Tiles Machinery's Fully Automatic, Semi auo & manual Hydraulic Mahines for manufacturing paver blocks(Coulourfull and without colour), cement & fly ash bricks, concrete blocks, hollow & solid blocks, kerb stones etc.\015\012Our Hydraulic Machines are driven by two types of technologies based

Grey Industrial Paver Block Making Machine

Price: 950000 INR/Unit

MOQ1 Unit/Units, Unit/Units, Unit/Units

ColorGrey

Product TypeBlock Making Machine

MaterialMS, Other

AutomaticYes

PLC ControlYes

Voltage220 to 240 Volt (v)

Automatic Fly Ash Brick Making Machine - 10 Cavity Design, 2400 Bricks/Hour Production Rate | Rust-Free, Corrosion Resistant, High Durability, Electric Power, PLC Control

Price: 1800000 INR/Unit

MOQ1 Unit/Units

Product TypeAutomatic Fly Ash Brick Making Machine

MaterialOther

TypeHollow Block Making Machine

ComputerizedNo

AutomaticYes

PLC ControlYes

Fly Ash Brick Making Machine - 2000-2400 Bricks/Hour, 10 H.P. Power, Blue Color | Fully Automatic, Excellent Load Capacity

Price: 2000000.00 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypeFly Ash Brick Making Machine

General UseCONSTRUCTION

ComputerizedNo

AutomaticYes

Warranty1 Year

Semi Automatic FlyAsh Brick Making Machine - 5 HP Motor, 900-1100 Bricks/Hour, Blue | Easy Operating Method, Heavy Duty Model, Hydraulic Pressure System

Price: 1200000 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeBrick Making

General UseIndustrial

MaterialFly Ash

Capacity900-1100 Pcs/hr

TypeHollow Block Making Machine

Automatic Fly Ash Bricks Plant (Endeavour- If1200) Machine Power: 14.625 Kilowatt (Kw)

Price: 1250000 INR/Set

MOQ1 Set/Sets

MaterialFly Ash

AutomaticYes

PLC ControlYes

MethodHydraulic Pressure

Machine Power14.625 Kilowatt (kW)

Voltage440 Watt (w)

Endeavour Intelligent Equipments Pvt. Ltd.

Mehsana

Trusted Seller

Trusted Seller9 Years

Super Seller

Super SellerHydraulic Pressure Automatic Nexus Fly Ash Brick Making Machine - Feature: Heat Insulation

Price: 1900000 INR/Unit

MOQ1 Unit/Units

TypeClay Brick Making Machine, Hollow Block Making Machine

FeatureLow Weight, Heat Insulation, Fire Resistant

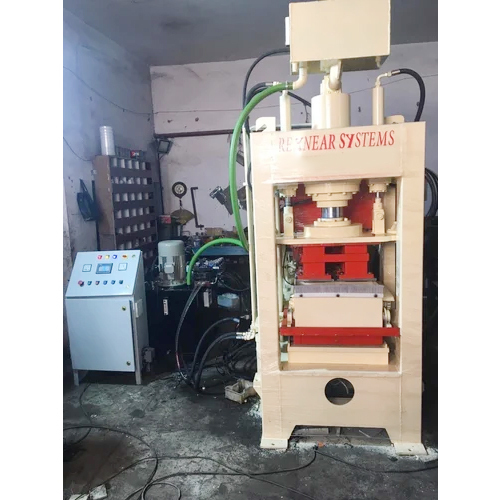

Automatic Fly Ash Bricks Machine 6, Brick Type: Solid

Product DescriptionAutomatic Fly Ash Bricks Machine

Rexon Hydraulics Private Limited

Ahmedabad

Trusted Seller

Trusted Seller4 Years

Super Seller

Super SellerAutomatic Fly Ash Brick Machine - 240V, 1000-1500 Bricks per Hour | Metal Build, PLC Control, Fully Automatic Operation, Clean White Finish

Price: 1150000 INR/Unit

MOQ1 Unit/Units

ColorWhite

Product TypeFly Ash Brick Machine

General UseMaking Brick

MaterialMetal, Other

AutomaticYes

PLC ControlYes

The Spartan Machinery

Ahmedabad

Trusted Seller

Trusted Seller5 Years

Super Seller

Super SellerTop Rated Products

Automatic Fly Ash Bricks Plant (Endeavour- If1200) Machine Power: 14.625 Kilowatt (Kw)

Endeavour Intelligent Equipments Pvt. Ltd.

FAQs Related to Fly Ash Brick Making Machine

- Set a Business Plan

- Select an ideal Location

- Availability of raw material

- Required Manufacturing equipment

- Investment

- Competition analysis

- License and permits

Fly Ash Brick Making Machine - 10 HP Motor, 09 Bricks Per Stroke at 230x110x75mm, Fully Automatic PLC Control with Oil Cooling System and Bottom Vibrator

Motor power10 hp

Brick output09 bricks/stroke

Brick size230X110X75mm

Strokes per minute5

Vibrator2 hp

Control panelPLC

Concrete Fly Ash Brick Making Machine - Color: Yellow And Blue

Price: 1950000 INR/Piece

MOQ1 Piece/Pieces

ColorYellow And Blue

Product TypeConcrete Fly Ash Brick Making Machine

General UseBRICK MAKING

MaterialOther, Mild Steel

Warranty1 Year

High Pressure Fully Automatic Fly-Ash Brick Making Machine Machine Power: 35 Hp

Price: 1850000 INR/Unit

MOQ1 Unit/Units

General UseFor Making Fly Ash Bricks

ComputerizedYes

AutomaticYes

PLC ControlYes

MethodHydraulic Pressure

Vibration TypeMold Vibration

Fly Ash Bricks Making Machine - Feature: High Durability

MOQ1 Unit/Units

General UseIndustrial

TypeAAC Plant

AutomaticYes

MethodAutoclaved Aerated Concrete

Voltage230 Volt (v)

FeatureHigh Durability

Fly Ash Brick Making Machine - 10HP Electric Power, 2HP Belt Conveyor, 2000 Bricks Production | PLC Control, Automatic Hydraulic Pressure Operation, Easy to Use

Price: 1025000 INR/Unit

MOQ1 Unit/Units

ColorOther, Blue

Product TypeFly Ash Brick Making Machine

General Useindustrial use

ComputerizedNo

AutomaticYes

Control SystemPLC Control

Blue White Fly Ash Brick Machine

Price: 1500000 INR/Set

MOQ1 Set/Sets

ColorBlue, Other

Product TypeBrick Machine

General UseFly Ash Brick making

MaterialOther, Metal

Control SystemPLC Control

FeatureSpace and energy efficient

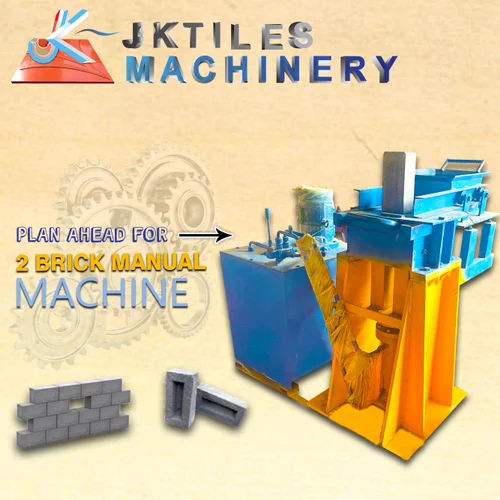

Manual Fly-Ash Brick Making Machine - Material: Fly Ash

Price: 7010 USD ($)/Piece

MOQ1 Piece/Pieces

Product TypeFly-Ash Brick Making Machine

General UseFly-Ash Brick Making Machine

MaterialFly Ash

ComputerizedYes

AutomaticNo

WarrantyService Warranty

Interlocking Fly Ash Brick Making Machine - Color: Blue And Yellow

Price: 1465000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue And Yellow

Product TypeInterlocking Fly Ash Brick Making Machine

General UseConstruction

ComputerizedNo

AutomaticYes

Warranty1 Year

6 Bricks Fully Automatic Fly Ash Bricks Making Machine - Color: Yellow

Price: 1150000 INR/Unit

MOQ1 Unit/Units

ColorYellow , Blue, White paint Coated

General UseIndustrial

MaterialOther, MS

Capacity7000 bricks Per Shift 8 Hrs Pcs/hr

AutomaticYes

PLC ControlYes

Fly Ash Brick Making Machine - 20,000 Bricks / 8 Hours Shift, Superior Quality Material, Smooth Functioning, Modern Technology Integration

MaterialSteel

Power18 HP

Production capacity20,000 bricks/8 hours

Dimensions2000 x 1500 x 2000 mm

Operating pressure150 Bar

Hydraulic oil capacity400 Liters

Green Heavy Duty Fly Ash Brick Making Machine

MaterialSteel

PowerElectric

Capacity1000 bricks/hour

DimensionsL x W x H

Weight1000 kg

Voltage220V

Automatic Fly Ash Brick Making Machine Capacity: 2400 Per Hour

Price: 2100000 INR/Unit

MOQ1 Unit/Units

ColorGray

Product TypeFly Ash Bricks, cement Bricks Making Machine

MaterialFly Ash

Weight (kg)3 kg Kilograms (kg)

ComputerizedYes

AutomaticYes

Shree Krishna Engineering Works And Fabrication

Ahmedabad

Trusted Seller

Trusted Seller4 Years

Premium Seller

Premium SellerWatch Fly Ash Brick Making Machine Videos

Flyash Bricks Making Machine, Vibro Compa, Etc

Fly Ash Brick Machine, Paver Block Machine

Food Processing Mill Plant, Hathu Mill Plant

Fly Ash Bricks Making Machine Machine Power: 220-440 Volt (V)

Price: 450000 INR/Unit

MOQ1 Unit/Units

Product TypeFly Ash Bricks Making Machine

General UseMaking Brick

AutomaticYes

Machine Power220-440 Volt (V)

WarrantyYes

Shankar Engineering Corporation

Burdwan

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerAutomatic Fly Ash Bricks Machine - Color: Blue

Price: 850000 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeFly Ash Bricks Machine

General UseIndustrial use

ComputerizedNo

AutomaticYes

PLC ControlNo

High Durability Pm18000 Automatic Fly Ash Bricks Making Plant

Price: 2750000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

ComputerizedNo

AutomaticYes

FeatureHigh Durability

WarrantyYes

Fly Ash Bricks Machine - 8 Bricks Per Stroke, 1900-2000 Bricks Hour, Low Maintenance, High Durability, Ruggedly Built, PLC Controlled

Price: 1650000 INR/Unit

MOQ1 Unit/Units

ColorYellow, Red, White

Product TypeFly Ash Bricks Machine

General UseBrick Making

MaterialOther

ComputerizedYes

AutomaticYes

Latest from Fly Ash Brick Making Machine

Cement Silo Manufacturers for Fly Ash Brick Making Machine

350000 INR

By:

Coimbatore Engineering Enterprises

Explore More Cities

Ready To Ship Fly Ash Brick Making Machine

What is fly ash brick machine?

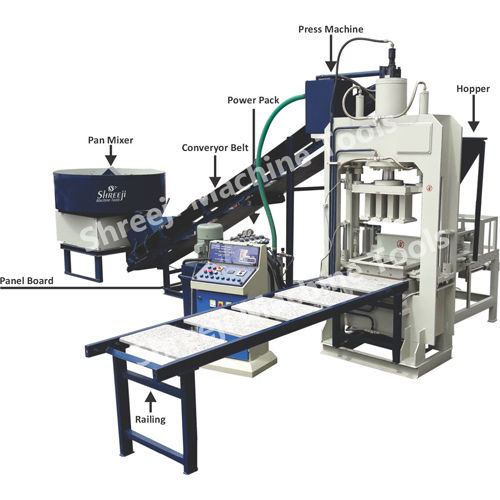

Bricks made from class C or F fly ash and water are known as fly ash bricks (FAB), and they are used in construction. Machines that produce bricks from fly ash have a low impact on the environment and last a long time. The 2 pan mixers included with the fly ash brick manufacturing equipment have a combined capacity of 500Kg, making them ideal for the task at hand. Making more bricks in less time is simple and fast with the help of this equipment.

The mixing of the basic materials is also the most crucial step in producing a fly ash brick. The mixing procedure determines the final product's quality and potency.

The manufactured input is then introduced into the hopper in step two. The hopper connects to the pressure machine, where the raw material is compressed before being used to fill the mold. It will be compressed into brick form at a later time.

Working process of fly ash brick making machine

1. Mixing Process

It is recommended to combine the sludge, lime, and gypsum with some water before proceeding with the mixing process. After that, mix in some sand and flies in the proportions given before. And stirred it until it was no longer combined. The primary raw material production phase is complete. The following ideal materials will be a blend of many components.

Gypsum

Crusher Dust 0 MM

Water

Cement

Sand

Fly Ash

Sludge Lime

Grit 4 MM to 8 MM

2. Pressing Process

The second stage involves putting the raw material manufacturers produced into the hopper. The raw materials enter the pressure machine via the hopper and are then pressed into the mold. In the future, it will be compressed into a brick form. A wooden or plastic pallet is used to press bricks while preserving their shape. In order to move these pallets beneath the pressure machine, only one or two workers may be needed.

3. Curing and Drying process:

The next step, after the first two have been completed, is to cure and dry the brick. Each brick goes through a pallet truck and into a secure room after it is manufactured. Then, after washing, it is hung up to dry in the open air for a period of 10–15 days.

In other words, this is the entire procedure for producing bricks. If you proceed thoughtfully and methodically, you won't find this to be a chaotic or difficult procedure. In most cases, the price of labor in this procedure is higher if you do not have a Fully Automatic Brick Making Machine.

To address these issues, Steel Land Machinery Works has developed a brick production machine that meets industry standards, greatly reducing the time and effort required to produce bricks.

The Automatic fly ash brick making machine requires simply the raw materials bin. When this is complete, the material can be transported to the pan mixer by conveyor belt. It will return to the hopper and be thoroughly mixed with the help of this belt.

Once that is done, the pallet will be fed into the machine without any further action being required. And the raw material, after being subjected to pressure, will emerge in the form of a brick on the top of the pallet. The bricks made by the pressure machine are then automatically stacked by the pallet stacker.

Types of fly ash brick making machine

Here are the top 5 types of fly ash brick making machines used in construction industry:

1. Hydraulic Manual Fly Ask Brick Machine

This is a semi-automatic Machine that can be handled manually. Because it relies solely on human muscle power, this model is the least expensive option. You need this one if you're just getting started and don't expect to have many large orders right away. Here are the specifications of the machine:

| Bricks Per stroke | 4 No. |

| Production Capacity | 500 Bricks per hour |

| Production | 4000 Bricks per shift |

| Vibration Motor | 1 HP |

| Hydraulic Motor | 2 HP |

| Motor Type | Single Phase/Three Phase |

| Oil Tank | 50 Liter |

| Hydraulic Pressure | 15-20 Tonnage |

| Man Power | 4-6 |

| Raw Material | Stone Dust, Fly Ash, OPC 53 Grade Cement |

| Brick Type | Solid |

2. Semi Automatic Fly Ask Brick Machine

You shouldn't worry about not being able to afford the fully Automatic Fly Ash Brick Making Machine. The machine's semi-automatic mode may work well for your needs.

| Automatic Grade | Semi-Automatic |

| Production Capacity | 750 Bricks per day |

| Voltage | 410 V |

| Material | Mild Steel |

| Motor Power | 15 HP |

| Power Surface | Electric |

| Surface Finish | Colored Coated |

| Oil Tank | 210 Liter |

3. Hydraulic Fly Ash Brick Making machine

The machine is semi-automatic and it can make 510 bricks per hours.

Specifications:

| Usage | For Brick Making |

| Voltage | 415 V |

| Power Source | Electric |

| Oil Tank | 100 liter |

| Capacity | 510-20 bricks per hours |

| Material | Mild Steel |

| Cycling Capacity | 12-15 Sec |

| Motor Power | 5 HP |

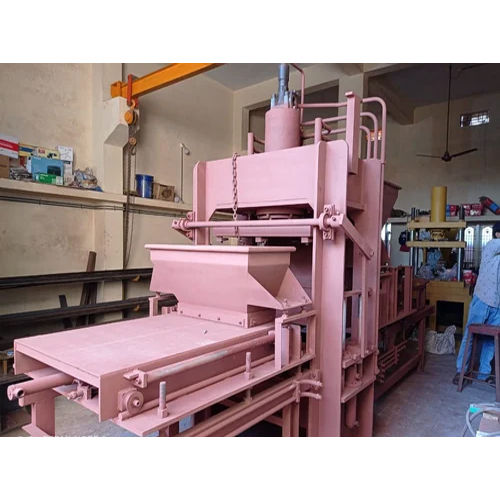

4. Fully Automatic Fly Ash Brick Making Plant

In the manufacturing industry, this is the standard model. The machine runs on electricity and needs only one or two people to operate it throughout production.

Specifications:

| Tonnage Capacity | 40 Ton |

| Total Plant Power Requirement | 15 HP, Three Phase |

| Man Power | 7-8 Person per shift |

| Oil Tank | 190 Liter |

| Mold Size | 9x4x3 |

| Raw Material | Fly Ash 50-60%+ Stone Dust 40-30% + Lime or Cement 8-9% + 1-2% Zipsum Powder |

| Method | Hydraulic Pressure |

| Capacity | 700-800 Bricks per hour |

| Production | Bricks as you want |

| Required Area | 40 ft. x 20 ft. |

5. Rotary Fly Ash Bricks Plant

Specification:

| Tonnage Capacity | 40 Ton |

| Power requirement | 10.00 Hp, 3 Phase |

| Oil Tank | 210 liter. |

| Man Power | 6-7 persons per Shift |

| Required Area | 350 sq. feet |

| Mold Size | 9 x 4 x 3 |

Uses & benefits of fly ash brick making machine

This equipment is the best there is for producing quality fly ash bricks. There are several benefits that the Automatic Fly Ash Brick Making Machine may provide to producers. Because of these merits, the device has gained widespread acceptance in its field. Here are some of the most typical and significant gains from making use of it.

1. Extremely Effectiveness

The primary advantage of the equipment is its rapid brick production. Because of this, the factory can fulfill more large orders in a timely manner. A well-oiled production machine will never let you down when it comes to on-time order fulfillment.

2. Low-Down on Upkeep

Everyone relies on constant and rapid output. Upsetting the entire production schedule, maintenance tasks can take a long time to perform. The ideal answer is found in these Fly Ash Brick Making Machines. All of these machines just need a once- or twice-yearly tune-up. As a result, there are no interruptions in the production process, and the manufacturing cycle can continue indefinitely.

3. Lengthened Stability

Each component of the machine was carefully inspected before it was assembled to ensure the highest possible quality. The end result is a top-tier machine that can keep cranking out high-quality goods for years to come.

4. Making High-Quality Bricks

These machines are designed by Fly Ash Brick Making Machine Manufacturers using cutting-edge production methods. It's useful for making sure that your manufacturing of building supplies keeps up with market demand. This results in the highest quality fly ash bricks possible in terms of strength, structural integrity, and longevity.

Conclusion

Investigate the company's services and procedures before committing to the purchase of a machine. We have reached a consensus on the significance of the Automatic Fly Ash Brick Making Machine after thoroughly discussing all of its features. It's a wonderful present for everyone working in the construction materials industry. The machine's fully automated nature means it may support the user in a wide variety of ways while also increasing their output. The variety of models, including fully automatic and semi-automatic equipment, gives producers lots of leeway. If the fully automatic model is out of reach financially, the semi-automatic option is a good second choice. These machines will, without a shadow of a doubt, prove to be a worthwhile financial investment.

Fly Ash Brick Making Machine Price List

This Data was Last Updated on 2025-04-03

Fly Ash Brick Making Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Royal Tile Machines New Delhi, India | 15 Years |

Myravya Engineering India Pvt. Ltd. New Delhi, India | 13 Years |

Laxmi Engineering Works Ahmedabad, India | 11 Years |

Endeavour Intelligent Equipments Pvt. Ltd. Mehsana, India | 9 Years |

Rexnear Systems Greater Noida, India | 9 Years |

Kailash Engineering Morbi, India | 8 Years |

Bharat Tiles Machine Product Noida, India | 8 Years |

Hardic Engineering Ahmedabad, India | 7 Years |

Possible Machines Nashik, India | 7 Years |

Everon Industries Coimbatore, India | 6 Years |

Upcoming Tradeshows

International Summit & Expo on Bioenergy Value Chain 2025

Thu, 08 May, 2025 - Fri, 09 May, 2025

China (Wenzhou) International Leather, Shoe Material & Shoe Machinery Fair 2025

Fri, 22 Aug, 2025 - Sun, 24 Aug, 2025

INDIAN ICE CREAM CONGRESS & EXPO 2025

Mon, 06 Oct, 2025 - Wed, 08 Oct, 2025

World Mithai & Namkeen Convention & Expo 2025

Fri, 19 Dec, 2025 - Sun, 21 Dec, 2025

Smart Home Expo 2025

Thu, 08 May, 2025 - Sat, 10 May, 2025

CPHI & PMEC China 2025

Tue, 24 Jun, 2025 - Thu, 26 Jun, 2025

International Crop Science Conference and Exhibition 2025

Tue, 10 Jun, 2025 - Wed, 11 Jun, 2025

WORLD OF HOSPITALITY EXPO 2025

Thu, 12 Jun, 2025 - Sat, 14 Jun, 2025

MachAuto 2025

Fri, 25 Jul, 2025 - Mon, 28 Jul, 2025

PU TECH 2025

Wed, 09 Apr, 2025 - Fri, 11 Apr, 2025

Popular Categories