- Tradeindia

- Shredding Machine

- Metal Shredder Machine

Metal Shredder Machine

(159 products)Capacity Heavy Metal Shredder for Plastic Waste with 150 kW Power Output

Power Output150 kW

Shredding Capacity20 tons/hr

Feed Opening1200x800 mm

Weight7 tons

Voltage380V

Control SystemPLC

Ss-Gmp Shredder Machine Capacity: 50-500 Kg/Hr

Price: 250000 INR/Piece

MOQ1 Piece/Pieces

ColorGrey

Product TypeSS-GMP Shredder Machine , Other

MaterialStainless Steel

AutomationAutomatic

DisplayOther

Voltage380 Volt (v)

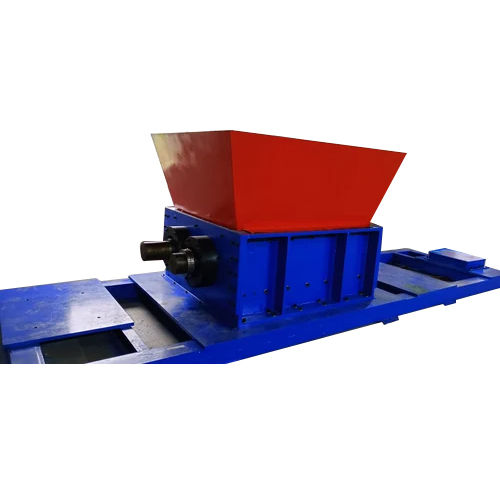

Metal Shredder Machine - Automatic Grade: Automatic

MOQ1 Piece/Pieces

Warranty1 Year

Voltage220-440 Volt (v)

Automatic GradeAutomatic

Control SystemSwitch

Capacity1-500 Kg/hr

Metal Shredder Machine - Automatic Grade: Yes

Price: 2500000 INR/Unit

MOQ1 Unit/Units

Processing TypeMetal Shredder Machine

Voltage220-240 Volt (v)

Warranty1 Year

Control SystemManual

Automatic GradeYes

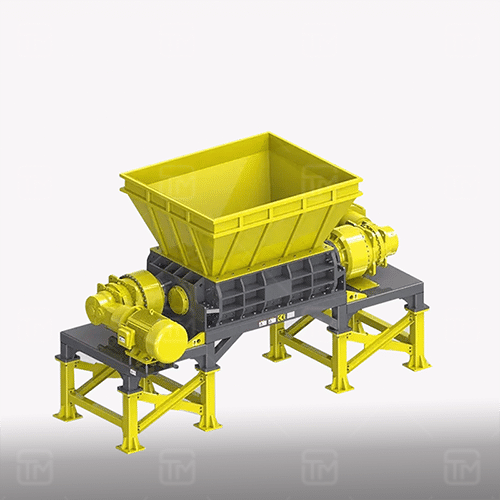

Capacity High Efficiency Double Shaft Industrial Metal Shredder Machine

Motor Power15 kW

Shredding Capacity5000 kg/hr

Blade MaterialHardened Steel

Cutting Speed40 RPM

Feed Width500 mm

Voltage380V

Capacity High Performance Electric Shredder Machine for Paper with Cross Cut

Shredding Capacity10-15 sheets

Shredding TypeCross-cut

Bin Capacity20 liters

Noise Level< 60 dB

Shredding MaterialPaper

Shreding Speed2 m/min

Rangani Engineering Pvt. Ltd.

Shapar

Super Seller

Super Seller5 Years

Capacity Heavy Duty Plastic Shredding Machine with 15 kW Motor and 500

Motor power15 kW

Shredding capacity500 kg/hr

Cutting chamber600x400 mm2

Automation gradeAutomatic

Weight1500 kg

Warranty1 Year

Industrial Rotary Shredder Machine

Price Trend: 100000.00 - 300000.00 INR/Unit

MOQ1 Unit/Units

Payment TermsCash Advance (CA)

Supply Ability2 Per Day

Delivery Time10 Days

Dual Shaft Rotary Shredder

Price: 5000000 INR/Unit

MOQ1 Piece/Pieces

FOB PortEx Works, Delhi

Payment TermsCheque, Others

Supply Ability5 - 6 Per Month

Aluminum Shredder - 1500 Kg/hr Capacity, 2500 Kg Weight, Automatic Operation | Steel Build, Versatile Scrap Recycling, Efficient Smelting Charge Preparation

Price: 4875.0 USD ($)/Set

MOQ1 Set/Sets

Product TypeScrap Metal Recycling Machine

MaterialSteel

Capacity1500 Kg/hr

Weight (kg)2500 Kilograms (kg)

AutomaticYes

Voltage220V/380V/415V/440V/Customized Volt (v)

Avanti HS 404 CCX - High Grade Alloy Steel, 2-4 mm Cross-Cut | Automatic Auto-Stop Function, 1-500 kg/hr Industrial Shredding Capacity

Price: 300000 INR/Unit

MOQ1 Unit/Units

TypeShredder Machine

UseIndustrial

Cut Size2-4 mm

Auto-StopYes

Top Rated Products

Capacity Heavy Metal Shredder for Plastic Waste with 150 kW Power Output

Zigma Machinery & Equipment Solutions

Capacity High Performance Electric Shredder Machine for Paper with Cross Cut

Rangani Engineering Pvt. Ltd.

Capacity Heavy Duty Plastic Shredding Machine with 15 kW Motor and 500

Vakratund Invention India Private Limited

FAQs Related to Metal Shredder Machine

Scrap metal shredders are used to break down scrap metal into manageable, moveable pieces. They come in a range of sizes, from small units that can shred pennies and tin cans to huge machines with 10,000 horsepower motors that can shred 4,000 tonnes of metal a day. As part of the end-of-life vehicle recycling process, these larger machines shred items such as cars, bulk drums and virtually any other type of scrap metal. Shredders are available with different cutting methods such as horizontal or vertical shafts, single, double, triple or even quadruple shafts. Depending on the type of material to be shredded, the shafts can have multiple blade types with claws of different thicknesses. In addition to the number of shafts, shredders can operate at high, medium or low speeds. Typically, the types of shredders used in scrap metal recycling operate at low speeds with high torque, enabling them to efficiently chew through large pieces of metal. Large pieces of scrap metal, such as crushed old vehicles, are fed into shredders on an industrial scale. They pass through the feed pipe into the shredding area where powerful hammers rotate and shred the metal.

Plastic Bottle Shredder Machine - Automatic Grade: Semi Automatic

Price: 95000 INR/Unit

MOQ1 Unit/Units

MaterialStainless Steel

Automatic GradeSemi Automatic

Capacity500 Kg/hr

Processing TypeStandard

Voltage200 - 250 Volt (v)

Warranty2-5 Years

Industrial Strip Cut Shredder Machine

Price: 80000 INR/Unit

MOQ1 Unit/Units

Delivery Time1 Week

Sample PolicyContact us for information regarding our sample policy

Packaging DetailsStandard

Capacity High Efficiency Automatic Shredder Machine for Industrial Use

Motor Power2 HP

Shredding Capacity100 kg/hr

Voltage220V

Usage/applicationIndustrial

Blade MaterialStainless Steel

Hopper SizeLarge

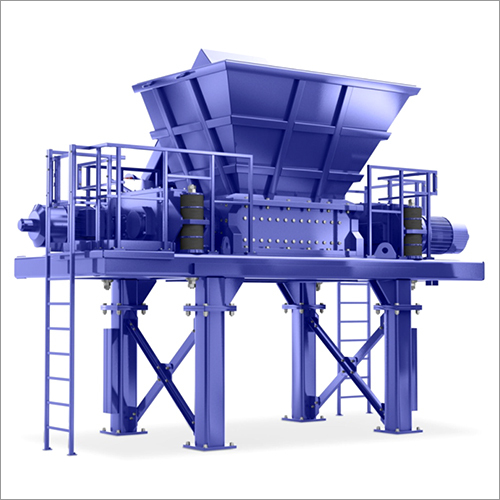

Metal Shredder Machine - Automatic Grade: Automatic

Price: 10500000 INR/Unit

MOQ1 Unit/Units

Capacity>2000 Kg/hr

Automatic GradeAutomatic

Warranty1 Year

Voltage415 Volt (v)

MaterialMild Steel

Motor Power60 Horsepower (HP)

Municipal Solid Waste Shredding Machine (Twin Shaft Shredder) - Operating Type: Automatic

Price: 365000 INR/Piece

MOQ1 Piece/Pieces

Product TypeOther, Municipal Solid Waste Shredding Machine (TWIN SHAFT SHREDDER)

Power SourceElectricity

Operating TypeAutomatic

Warranty1 YEAR

Usage & ApplicationsIndustrial

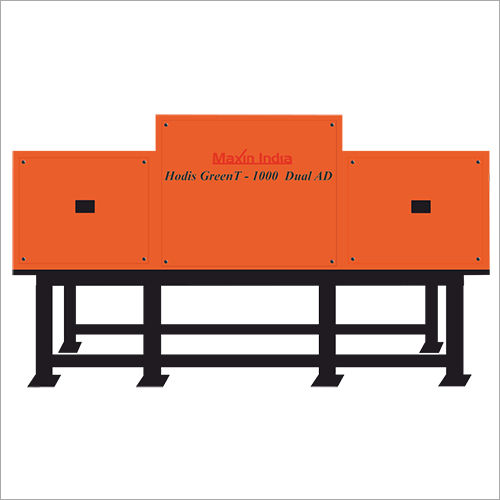

Maxin Iro 750 Dual Shaft Shredding Machine - 40 HP Dual Motor, 1500-2000 Kg/Hr Capacity, White and Black Finish | Automatic, 2 Ton Weight, 750 mm Cutting Width

Price: 1895000 INR/, Unit

MOQ1 , Unit/Units

ColorOther, Multicolour

Product TypeMetal Shredder Machine

General UseMetal Waste

MaterialSteel

Weight (kg)2500 Kilograms (kg)

ComputerizedNo

Mayslynn Recycling Equipment And Technology Co., Ltd

Taizhou City

High Efficiency 12 TPH Automatic Biomass Shredder Machine

Price: 550000 INR/Unit

MOQ1 Unit/Units

Warranty1 Year

Automatic GradeAutomatic

Capacity12 T/hr

Control SystemManual

MaterialMild Steel

Steel Shredding Machine - Automatic Grade: Automatic

Price: 50000 INR/Unit

MOQ1 Unit/Units

Automatic GradeAutomatic

Warranty1 Year

Voltage415 Volt (v)

Capacity500 Kg/hr

Control SystemPLC Control

Hu-mera Engineering

Ghaziabad

Trusted Seller

Trusted Seller1 Years

Ib-Ews-250 Kg Double Shaft E Waste Shredder Machine - Automatic Grade: Automatic

Price: 550000 INR/Unit

MOQ1 Unit/Units

Automatic GradeAutomatic

Capacity500-1000 Kg/hr

Warranty1 Year

Motor Power10 Horsepower (HP)

Control SystemHuman interface

Processing TypeCommon

Automatic Single Shaft Plastic Shredder Machine

Price: 4200 USD ($)/Unit

MOQ1 Unit/Units

TypeSingle Shaft Plastic Shredder Machine

MaterialMetal

ComputerizedNo

Automatic GradeAutomatic

Automatic Mild Steel Shredder Machine - Capacity: 100 Kg/Hr

Price: 130000 INR/Unit

MOQ1 Unit/Units

Motor Power10 HP Horsepower (HP)

Control SystemManual

Capacity100 Kg/hr

Voltage220-440 Volt (v)

Warranty1 Year

Automatic GradeFully Automatic

Body Industrial Electric Hammer Mill Shredder 500 kg/hr Green Automatic

Shredding Capacity500 kg/hr

Voltage380V

Frequency50Hz

Rotor Speed1500 RPM

Feed Size200 mm

Usage/applicationIndustrial

Metal Shredder Machine

MOQ1 Piece/Pieces

FOB PortMumbai

Payment TermsCash Against Delivery (CAD), Cheque, Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Delivery Point (DP), Days after Acceptance (DA), Cash in Advance (CID), Cash Advance (CA)

Supply Ability10-30 Per Month

Empty Bunch Shredder Machine - Cutter Type: Automatic

Price: 1502000 INR/Unit

MOQ1 Unit/Units

TypeShredder Machine

UseFor Industry

Cutter TypeAutomatic

Auto-StopYes

Motor TypeElectric

Semi Automatic Single Shaft Rotary Shredder

Price: 1000000 INR/Unit

MOQ1 Unit/Units,

Operating TypeSemi Automatic

Surface TreatmentPainted

Warranty1 Year

Usage & ApplicationsIndustrial

Latest from Metal Shredder Machine

Metal Shredder Machine

By:

Aim Industries

Double Shaft Shredder Machine Powerful Factory Production Metal Shredder Machine

8875.0 USD ($)

By:

Henan Tomings Machinery Co Ltd

Metal Shredder Machines

By:

Skyline Automation

Explore More Cities

Ready To Ship Metal Shredder Machine

What is a Metal Shredder Machine and How Does it Work?

In addition to the number of shafts, shredders can operate at high, medium or low speeds. Typically, the types of shredders used in scrap metal recycling operate at low speeds with high torque, enabling them to efficiently chew through large pieces of metal.

Large pieces of scrap metal, such as crushed old vehicles, are fed into shredders on an industrial scale. They pass through the feed pipe into the shredding area, where powerful hammers rotate and shred the metal. Magnets are used to separate the shredded material into ferrous and non-ferrous components before it is transported along conveyor belts and finally spat out of the opposite side of the machine in two separate piles for further sorting.

Scrap metal shredders are used to break down scrap metal into manageable, moveable pieces. They come in a range of sizes, from small units that can shred pennies and tin cans to huge machines with 10,000 horsepower motors that can shred 4,000 tonnes of metal a day. As part of the end-of-life vehicle recycling process, these larger machines shred items such as cars, bulk drums and virtually any other type of scrap metal.

Shredders are available with a variety of cutting methods, such as horizontal or vertical shafts, single, double, triple or even quad shafts. Depending on the type of material to be shredded, several types of blades with claws of different thicknesses can be produced for the shafts.

The Benefits of Using a Metal Shredder Machine

-The production of hot metal during metal shredding is very high compared to the amount fed in.

-The hot metal produced has a clear, precise and consistent chemistry.

-Together with the lower sulphur concentration, electrode breakage is reduced.

-The hot metal has greater capacity or endurance.

-The hot metal consumes less electricity per tonne.

-Recycling helps to reduce environmental risks and air pollution.

-When combined with other materials, crumbled scrap is easier to handle and produces a dense mixture.

-Ferrous and non-ferrous materials are automatically separated from the shredded scrap.

-Operators can choose to automate or manually operate the shredder controls.

Single Shaft Industrial Shredders

A single shaft, hydraulic pusher plate and filter screen are used to ensure precise size reduction. It is used to shred things like cardboard, plastic, wood, rubber and other similar materials.

Double Shaft Shredders

A twin shaft shredder is another name for this type of shredder. Double shaft shredders are part of the double shaft shredding machine. The rotating blades on the two shafts shred a significant proportion of the input material into smaller pieces. Twin shaft shredders also rotate at a constant speed to reduce the amount of dust generated during the shredding process.

Three Shaft Shredders

A three-shaft shredder has three blades, each rotating at a different speed. They are most commonly used for shredding metals, aluminium, food waste, hazardous waste and medical waste.

Four-Shaft Shredders

It has four shredding rollers with blades of different sizes. To improve production efficiency, pre-shredding and secondary shredding can be performed. The output can also be divided into several sizes.

Grinders

These grinders use abrasives to reduce the input material to small pieces. The output is reduced to half an inch or less. There are horizontal grinders and tub grinders; the latter has a conveyor belt and the former is top leading.

Granulators

Granules are produced from the input material so that it can be used to make new materials. The input material is then reduced to usable granules by the blades of the rotor, which is driven by an electric motor.

Commercial Shredders

They have a drum that rotates and has blades on it. The input material is shredded as the drum rotates. Newspapers, plastics and wood chips are all shredded.

Commercial Cutter

The slitter, as the name suggests, is used to reduce wide rolls of input material into narrower rolls. The width of the rolls is reduced. Slitter rewinders and roll slitters are the two types and are used depending on the application and material.

Key Features to Look for When Buying a Metal Shredder Machine

Usability

The most important aspect to consider is how easy the equipment is to use. Whether you are considering a vertical plastic baler or a metal shredder, it is imperative that you have a firm idea of how the equipment will be used before making any purchases. To get to the next step, work out how much and how often you will be shredding metal.

Safety issues

There are many potential risks when operating machinery such as a scrap metal shredder. The next item on your list should therefore be your safety. Check that the machine is fitted with the necessary safety devices and, if so, determine whether these devices provide the necessary level of safety while the machine is shredding.

Capacity

If you're interested in how much metal the shredder can handle, look at its capacity. Generally speaking, if you work with a lot of metal on a daily basis, especially in large quantities, it is recommended that you use a high-capacity metal shredder. This is particularly true when working with smaller quantities of metal. You'll get the job done faster.

Maintenance and Upkeep of Metal Shredder Machines

1. Routine replacement and maintenance of wear parts:

The blade is a critical component of the metal shredder and is used regularly. Pay close attention to blade maintenance and regular cleaning. Don't wait until the machine is ruined by the unfavourable elements of the environment that the shredder processes. Pay attention to lubrication and cleaning during routine use.

2. Take effective safety precautions in case the metal shredder breaks down.

It's also important to take maintenance steps to protect the metal shredder equipment from dust, corrosion and moisture when it's not in use or idle. Moisture should be avoided as it can cause internal rusting of machine parts. The machine's operating environment is compromised, making it easy for it to become paralysed and difficult to repair when it is used again. Many products on the market operate on the same principle, substituting seven points for three. Regular maintenance is essential.

Metal Shredder Machine Price List

Product Name | Expected Price |

|---|---|

| Shredding Machine | 150000 |

| Automatic Mild Steel Shredder Machine | 130000 |

| Semi Automatic Stainless Steel Shredder Machine | 125000 |

| Heavy Duty Shredder Machine | 300000 |

| Steel Shredding Machine | 50000 |

| Industrial Shredder Machine | 600000 |

| Shredder Machine | 150000 |

| Shredder Machine | 25000 |

| Automatic Mild Steel Shredder Machine | 130000 |

| Shredding Machine | 85000 |

This Data was Last Updated on 2025-04-23

Metal Shredder Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Amey Shredtech Private Limited Thane, India | 18 Years |

Zigma Machinery & Equipment Solutions Coimbatore, India | 14 Years |

Indus Engineering Projects India Pvt Ltd New Delhi, India | 14 Years |

Idea Holding Limited Ludhiana, India | 12 Years |

Shredders & Shredding Co. Mumbai, India | 11 Years |

Maxin India Machinery Manufacturers Private Limited Coimbatore, India | 9 Years |

Mayslynn Recycling Equipment And Technology Co., Ltd Taizhou City, China | 9 Years |

Advance Recycling Solutions Llp New Delhi, India | 8 Years |

Kaminox Industries Thane, India | 8 Years |

Kavinson India New Delhi, India | 7 Years |

Upcoming Tradeshows

FoodTech Kerala 2025

Thu, 22 May, 2025 - Sat, 24 May, 2025

Copper China 2025

Wed, 09 Jul, 2025 - Fri, 11 Jul, 2025

INDIAN ICE CREAM CONGRESS & EXPO 2025

Mon, 06 Oct, 2025 - Wed, 08 Oct, 2025

India Hospitality + F&B Pro Expo - Goa 2025

Fri, 09 May, 2025 - Sun, 11 May, 2025

Smart Home Expo 2025

Thu, 08 May, 2025 - Sat, 10 May, 2025

CPHI & PMEC China 2025

Tue, 24 Jun, 2025 - Thu, 26 Jun, 2025

International Crop Science Conference and Exhibition 2025

Tue, 10 Jun, 2025 - Wed, 11 Jun, 2025

WORLD OF HOSPITALITY EXPO 2025

Thu, 12 Jun, 2025 - Sat, 14 Jun, 2025

MachAuto 2025

Fri, 25 Jul, 2025 - Mon, 28 Jul, 2025

Asia Labex 2025

Wed, 11 Jun, 2025 - Fri, 13 Jun, 2025

Popular Categories