- Tradeindia

- Paper, Paper Converting Machinery

- Paper Punching Machine

Paper Punching Machine

(114 products)Capacity Heavy Duty Black Ergonomic Paper Punching Machine for Office and Industrial Use

Dimensions10x5x8 inches3

MaterialStainless Steel

Punch Capacity30 sheets

Hole Size6mm

Handle TypeErgonomic

ColorBlack

Paper Hole Punching Machine

Punch Capacity30 sheets

Hole Size6 mm

MaterialSteel

Operation ModeManual

ColorGrey

Weight2 kg

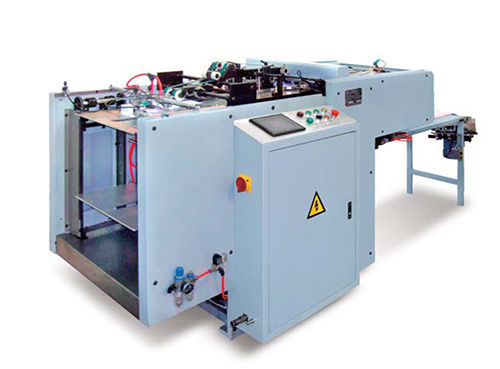

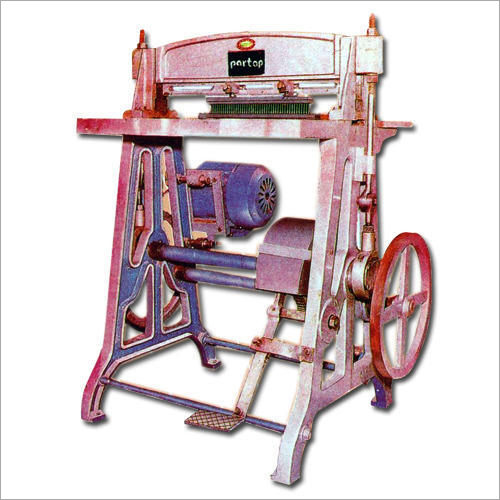

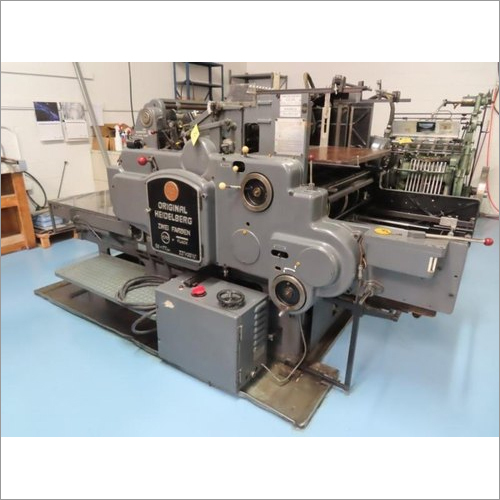

Semi-Automatic Paper Punching Machines

Price: 200000 INR/Unit

MOQ1 Unit/Units

Usage & ApplicationsIndustrial

Paper TypeAll

MaterialOther Material

Power SourceElectrical

Plastic Paper Punching Machine - Steel Build, Office Application, Industrial Usage, Warranty Included

MaterialPlastic

OperationManual

Punch TypeSingle Hole

Punch Capacity10 Sheets

Dimensions5x2x3 inches

Weight300 grams

Bhagwati Stationery & Xerox & M/s.bhagwati Enterprises

Navi Mumbai

Trusted Seller

Trusted Seller2 Years

Capacity Manual Semi-Automatic Steel Eyelet Punching Machine for 3 to 10mm

Power Supply220V

MaterialSteel

Operation TypeManual

Eyelet Size3-10mm

Weight35kg

Dimensions40x30x20cm3

Manual Hand Operated D Cut Punching Machine for Steel Applications

Feeding TypeManual

Cut TypeD-Cut

Power SourceManual

MaterialSteel

ApplicationPunching

Operation ModeHand-Operated

Unique India Paper Teknix

Coimbatore

Trusted Seller

Trusted Seller6 Years

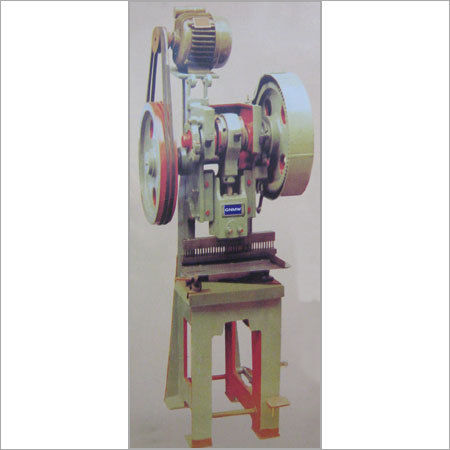

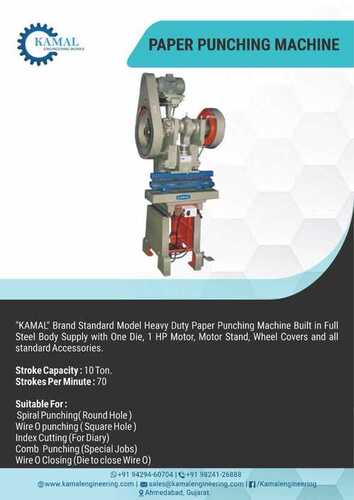

Namibind Die Changeable Power Press Punching Machine 5 Ton Capacity, 140-150 Sheets Per Punch - Automatic Grade: Semi-Automatic

Price: 165000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

MaterialMS

ComputerizedNo

Automatic GradeSemi-Automatic

Voltage110-220 Volt (v)

Warranty1 Year

3000 Kg Paper Die Punching Machine - Color: White

Price: 300000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

Product TypeOther, Die Punching Machine

TechnologyCNC

Power SourceElectricity

Operating TypeSemi Automatic

Surface TreatmentPainted

Use Premium Metal Paper Punching Machine with Double Helical Gears

Dimensions12x8x14 inches3

Weight5 kg

Punching Capacity30 sheets

MaterialMetal

ColorGrey

Handle TypeLever

Medium Size Paper Punching Machine - Alloy Steel & Plastic, 22 Sheets Capacity & 5.5mm Diameter Punch | Human Machine Interface, Manual Control, Multi-Color Options, 1-Year Warranty

Dimensions20x15x10 cm3

Weight2 kg

Punch Capacity20 sheets

MaterialSteel

ColorBlue

Handle TypeLever

Paper Punching Machine - Lightweight Standard Size | User-Friendly, Smooth Functioning, Quality Tested, Easy to Carry

Price: 60 INR/Piece

MOQ500 Piece/Pieces

Product TypeOther

UsagePaper punching

SizeStandrad

ApplicationOffices, etc.

FeatureLight weight

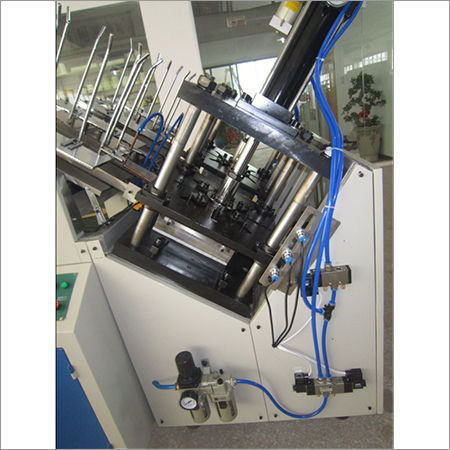

SizeHigh Volume Automatic Reel to Reel Paper Punching Machine

TypeReel-to-Reel

CapacityHigh Volume

MaterialSteel

Power3 Phase

SpeedAdjustable

ControlPLC

Top Rated Products

Capacity Heavy Duty Black Ergonomic Paper Punching Machine for Office and Industrial Use

Senior Paper Packing Machinery Mfg. Co.

Plastic Paper Punching Machine - Steel Build, Office Application, Industrial Usage, Warranty Included

Bhagwati Stationery & Xerox & M/s.bhagwati Enterprises

FAQs Related to Paper Punching Machine

Who are the top paper punching machine manufacturers in India?

- Senior Paper Packing Machinery Mfg. Co.

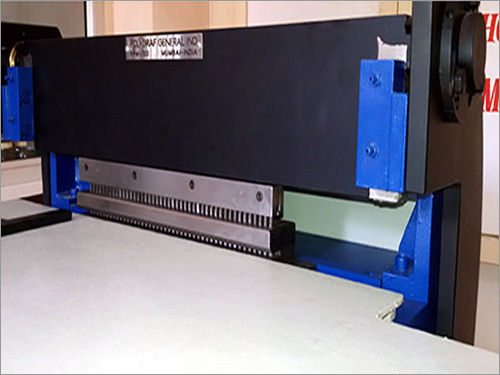

- Polygraf General Industries

- Printech Machineries

- Kavinson India

- Unique India Paper Teknix

- Monotech Systems Limited

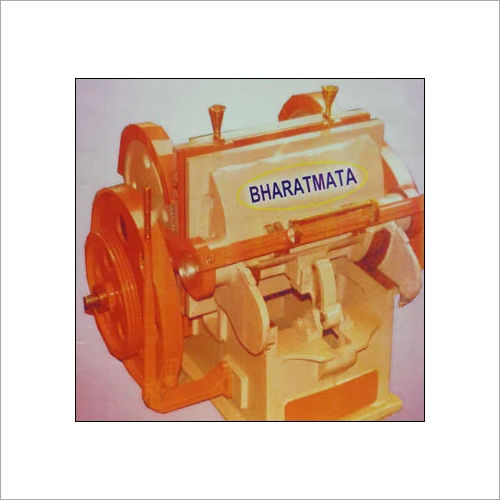

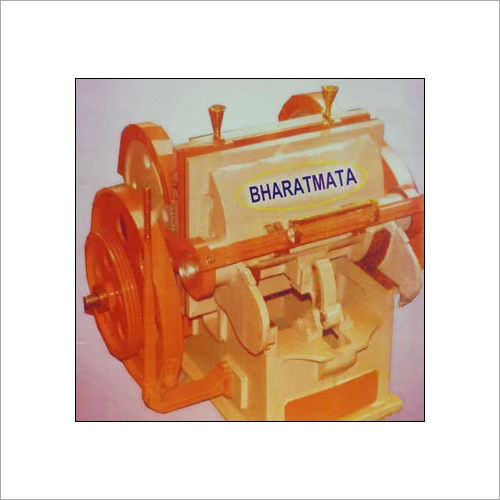

- Bharatmata Engineering Works

- Bhagwati Stationery & Xerox & M/s.bhagwati Enterprises

Which cities have the largest number of paper punching machine suppliers?

- Delhi

- Kolkata

- Mumbai

- Pune

- Chennai

- Bengaluru

- Surat

- Coimbatore

- Ghaziabad

- Faridabad

- Indore

- Gurugram

- Noida

- Vadodara

- Bhopal

- Howrah

- Ludhiana

- Madurai

- Pudukkottai

- Chinchwad

What is the price range for paper punching machine offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| National Industries | INR | Wy 290a Two Punch Paper Punching Machine | 8000 |

| Bandhani Techno Tools | INR | Paper Punching Machine | 330 |

| Hardev industries | INR | Paper Die Punching Machine | 400000 |

| ONE MORE STEP ENTERPRISE | INR | 1.2 Mm Thickness Paper Punching Machine | 180 |

| LOKNATH HARDWARE AND MACHINARY | INR | 20 Sheet Capacity Blue Steel Plastic Paper Punching Machine | 45 |

| METRO Trading Co. | INR | Grey Paper Punching Machine With 12 Sheets Punching Capacity & 5.50mm Diameter | 78 |

| Shree Laxmi Enterprises | INR | Black Color Paper Punching Machine For Offices And School Supply | 100 |

| Sun Enterprises | INR | Medium Size Paper Punching Machine | 120 |

| TAIYEBJI WIRES PVT. LTD. | INR | Single Phase Paper Punching Machine | 100000 |

How many trusted sellers are available for paper punching machine?

- SENIOR PAPER PACKING MACHINERY MFG. CO.

- Monotech Systems Limited

- BHAGWATI STATIONERY & XEROX & M/S.BHAGWATI ENTERPRISES

- UNIQUE INDIA PAPER TEKNIX

What is the minimum order quantity for paper punching machine?

Do listed companies have registration & certifications?

- SENIOR PAPER PACKING MACHINERY MFG. CO.

- Monotech Systems Limited

- Sun Enterprises

What is the get latest price feature?

What types of payment methods are accepted by the paper punching machine suppliers?

MachineSemi Automatic File Master Multiple Hole Punching

Price: 415200.00 INR/Unit

MOQ1 Unit/Units

Product TypeOther, Punching Machine

Power SourceElectricity

Operating TypeSemi Automatic

Surface TreatmentGalvanized

Warranty1 Year

Usage & ApplicationsFor Punching Use

Advanced Automatic Paper Die Punching and Cutting Machine

Power Supply220V

Cutting Speed1000 sheets/hr

Machine Weight1500 kg

Die Sizecustomizable

Material TypePaper/Cardboard

Control SystemPLC

Machine Customizable High Precision Roll Die Punching

Price: 3500000.00 INR/Piece

MOQ1 Piece/Pieces

ColorCustomize

Power SourceElectricity

Operating TypeAutomatic

Surface TreatmentCoated

Warranty1 year

Production Capacity5 Ton/day

Black Ergonomic Heavy Duty Metal 2 Hole Paper Punch for Up to 30 Sheets

Holes2

MaterialMetal

Max Pages30

ColorBlack

Handle TypeErgonomic

Weight500g

Model Blue Steel and Plastic Ergonomic Paper Punch Machine for 20 Sheets

Capacity20 Sheets

MaterialSteel & Plastic

ColorBlue

TypePaper Punch

Usage/applicationOffice

PrecisionHigh

Heavy Duty Industrial Hydraulic Paper Punching Machine for High

TypeHydraulic

Capacity700 Punch/hr

Speed60 cycles/min

Power220V

MaterialSteel

Weight120kg

Capacity High Efficiency 1.2 Mm Thickness Paper Punching Machine with 150

Price: 180 INR/Piece

MOQ500 Piece/Pieces

Colorblue

GradeManual

TypePunching Machine

Materialplastic

Capacity150 pcs/min. Pcs/min

ComputerizedNo

Punching Machine - Plastic Material, 1.6 X 5.7 Inch Size | Hassle-Free Performance, Negligible Maintenance

TypeCentrifugal

Power5 HP

Voltage220V

PhaseSingle

MaterialPaper

Flow Rate100 L/min

Obinder Automatic Paper and Cardboard Cover Punching Machine for A3

Punching Speed150 sheets/min

Max Paper SizeA3

Power Supply220V

Operation ModeAutomatic

Material TypePaper/Cardboard

Punching Thickness5 mm

Capacity Heavy Duty Electric A4 Card Sheet Punching Machine with High

Power10 HP

Voltage220V

Pressure150 PSI

Tank Capacity100 Liters

Motor TypeElectric

Weight80 kg

Steel Ergonomic Manual Paper Punching Machine for 20 Sheets with 6 mm Holes

Punch Capacity20 Sheets

MaterialSteel: Operation Type: Manual

Hole Size6 mm

Number Of Holes2

ColorBlack

Base MaterialMetal

Minute Automatic Electric Paper Punching Machine for Office and Industrial Us

Punch Capacity30 sheets

Power Supply220V

Weight5 kg

Dimensions20x15x10 cm3

MaterialMild Steel

ColorGrey

Durable Black Steel Paper Punch Machine with Ergonomic Handle for 30 S

Punch Capacity30 Sheets

Hole Size6 mm

MaterialSteel

ColorBlack

Handle TypeErgonomic

BaseAnti-Slip

Use Power Driven Electric Paper Punching Machine for High Capacity

Punching Capacity30 Sheets

Power SourceElectric

MaterialSteel

Dimensions12x8x10 inches3

Weight5 kg

ColorGrey

Steel Heavy Duty Single Phase Manual Paper Punching Machine for Wire O

Punching Capacity20 Sheets

Machine Weight50 Kg

MaterialSteel

Dimensions600x400x300 mm3

Operation ModeManual

ColorBlue

Heavy Duty Manual Paper Punching Machine for Office Use with 20

Punch Capacity20 Sheets

Punch Diameter6 mm

MaterialSteel

ColorBlack

OperationManual

Weight5 kg

Latest from Paper Punching Machine

Paper punching machine

By:

Shiv Engineering Works

Heavy Duty Die Changeable Paper Punching Machine With Punching Capacity (45-50 Sheets)

95000 INR

By:

Kavinson India

Chrome Finish Manual Hand Operated Paper Punching Machine

By:

Roshan Traders

Explore More Cities

Ready To Ship Paper Punching Machine

Industrial Punching Machines: A Reliable Equipment for Punching Holes Through Metal

Industrial Punching machines are essential pieces of equipment that are used to punch holes or create shapes in sheets built using metals, plastic, paper, wood, etc. These machines work by applying a certain amount of required pressure to the materials with a tool called ‘punch’. The accuracy of these punching machines is off the charts and they are most commonly used for punching complex shapes out of the materials as per the system instructions. The use of automatic machines not only boosts productivity but also makes operations cost-effective by reducing the need for manual labor and waste of resources.

Types of Punching Machines Available

-

Manual Punching Machines

Manual punching machines are the inferior version of industrial variants that are used to manually punch a hole or shape in materials like paper, cardboard, etc. A user has to use physical force to apply pressure on the material by pressing a lever that forces the blade to easily punch through the material.

-

Hydraulic Punching Machines

Hydraulic-powered punching machines are generally for punching through high-density materials that have excellent thickness. These machines are powerful enough to cut through metal sheets and create complex shapes for further manufacturing processes. Various industries use these types of machines as they are pretty expensive for personal use. This benefits the company with higher productivity and workers by saving them from manual labor work.

-

CNC Punching Machines

These types of punching machines are best for industrial applications for mass production. These machines punch through metal sheets, wood, hard plastic, fiber, etc., with the help of computer-controlled functions. A worker or engineer can feed data into the system and the machine will execute the tasks according to it. With speed, accuracy, and efficiency CNC machines help boost production rates significantly.

Applications of Punching Machines Across Various Industries

-

Automotive

In automotive industries, these punching machines are used in the manufacture of various types of vehicles. The machine helps by carving out various types of complex shapes and is designed with high accuracy, out of metal sheets, which are then used to manufacture a wide range of components and frames of those vehicles. Without the perfect shape-punching processes, manufacturing these products manually will take a lot of time and resources.

-

Electronics

In the electronics industry, these machines are designed to provide metal shapes of various types to produce the essential components and parts of electronic devices. A punching machine is used for creating shapes out of various materials like metals, plastics, etc to manufacture items including CPU chips, cabinets, motherboards, and various other parts. Moreover, apart from the accuracy, these types of equipment also make operations cost-effective by using raw materials very efficiently.

-

Construction

The construction industry uses punching machines to create metal parts and frames for constructing large infrastructures. In construction projects, there is a driver range of materials used for manufacturing essential structures like metal, concrete, pop, etc. The punching helps to punch out different types of shapes out of these materials, which are then used for assembling different parts.

-

Packaging

In the packaging industry, this equipment plays a vital role by facilitating the manufacturing process of packaging materials that are used by various industries to pack and transport their products safely. Packaging materials are made of paper, cardboard, fabric, wood, plastic, etc., and punching machines are used to punch out custom shapes and designs out of these materials with smooth finishing.

-

Medical

In the medical industry, these machines are used to produce essential parts used for making medical devices. The process is the same as in the automotive industry, these equipment help to create custom shapes and designs out of various materials and help in the manufacturing process.

-

Mining

Punching machines are extensively used in the mining industry as they are capable of delivering the required force for punching out the materials from thick and hard rock formations, digging out the essential elements, creating ventilation shafts, constructing drainage channels, etc. These machines have become irreplaceable in the mining industry because of their high precision and accuracy.

-

Metallurgy

In the metal industry, CNC punching machines are used for accurately cutting holes or various types of shapes out of different materials including aluminum sheets, stainless steel sheets, and many more. Most premium quality equipment is sourced in this industry for consistent quality and continuous demand, to increase productivity.

Key Advantages of Using Punching Machines

-

Precision

The precision and accuracy of the punching machines are off the charts. They are designed to cut or shape the materials with perfection, and accurate dimensions. No matter what type of shape or design you want out of a plastic, metal, or cardboard sheet, this machine automatically handles all the operations. Moreover, the punching machines are programmed to complete repetitive tasks without compromising consistent quality.

-

Versatility

Punching machines are highly versatile, they are available in both manual and automatic variants to complete various types of industrial jobs. Both manual and automatic machines can handle various sorts of materials and cut through them like butter. Also, you can use a wide range of materials to cut through with these machines, it will just require some modifications to adapt. You can cut complex shapes through metals, paper, plastic, fiber, etc.

-

Speed

Some of the variants of punching machines like CNC punching machines are very well known for their speed and accuracy. They are most commonly used for mass production projects and offer lightning speed to achieve higher production rates. Hence, these machines are best if you have to deliver bulk orders within the promised time.

-

Automation

These machines are available in all variants including manual, semi-automatic, and fully automatic. If you are selecting the automatic model of the punching machine then definitely it will be the best choice because of its automation level. From feeding the material to cutting complex shapes to sending it for further processing, the complete operation can be automated with the help of it.

How to Choose the Right Punching Machine for Yourself?

There are multiple factors to consider before selecting the right machine for your facility:

-

Material Type

The very first thing you should be doing is, to find out about the type of material you are going to cut with it, as different types of materials have varying thickness and tensile strength. The machine must be able to cut through these types of materials conveniently otherwise your investment will not be worth it.

-

Types of Sizes and Shapes

These machines are designed to punch holes or shapes or various sizes in the material sheets including metal, wood, plastic, etc. So, you should find out how many types of complex shapes of various sizes it can create, that too with excellent accuracy.

-

Production Capacity

Check whether the machine is capable of producing the same value over the current or forecasted market demand you have. For the best results you must rely on the machine that is capable of producing a little more than you require, for higher returns in the long run.

-

Automation Level

If you’re sourcing an automatic punching machine then you must check its automation level, as it will directly decide on multiple factors including total manpower you require, usage of resources, volume of wastage, energy consumption, etc.

-

Overall Cost Over Budget

The best investment would be to have a machine that has more features within your budget. Make sure to include all the costs including maintenance costs, transportation charges, replacement costs, energy costs, etc in your budget.

Client Testimonials & Reviews

ChandanDas

MACHINE WORLD

In this locked down periods, you are doing fabulous job for Machine world company. So many many thanks to you.

YogenderKumar

VIKAS PRESS TOOLS

Tradeindia is good platform for business promotion, we are happy with the services of tradeindia.com.

Rajender

Khalsa Engineering Works

I am member of tradeindia since last 5 years and I am fully satisfied with tradeindia services. I have good number of inquiries from tradeindia Buyers, Promotion and visibility.

SandeepMehta

BALAJEE MACHINE TOOLS

I just want to thank you for all services provided by you on behalf of tradeindia as I am highly satisfied.

MayankSuthar

JMC PAPERTECH PVT. LTD.

We JMC Engineers have been associated with Infocom Network Ltd. since last six years and we are very happy with the services (www.tradeindia.com) rendered to us, which really gave us a new avenue to contact domestic as well as international buyers. We are a leading manufacturer and exporters of pulp paper and board making machinery. We have received valued inquires from our effective customers through their excellent network. We wish Infocom Network Ltd. to continue their services in years to come. We wish all the best to Infocom Network Ltd. team and thanks to their CRM support for their well support to us. Wishing you best for future.

Paper Punching Machine Price List

This Data was Last Updated on 2025-04-25

Paper Punching Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Senior Paper Packing Machinery Mfg. Co. Amritsar, India | 20 Years |

Polygraf General Industries Mumbai, India | 17 Years |

Printech Machineries Coimbatore, India | 7 Years |

Kavinson India New Delhi, India | 7 Years |

Unique India Paper Teknix Coimbatore, India | 6 Years |

Monotech Systems Limited Chennai, India | 4 Years |

Bharatmata Engineering Works Howrah, India | 3 Years |

Bhagwati Stationery & Xerox & M/s.bhagwati Enterprises Navi Mumbai, India | 2 Years |

Upcoming Tradeshows

FoodTech Kerala 2025

Thu, 22 May, 2025 - Sat, 24 May, 2025

Copper China 2025

Wed, 09 Jul, 2025 - Fri, 11 Jul, 2025

INDIAN ICE CREAM CONGRESS & EXPO 2025

Mon, 06 Oct, 2025 - Wed, 08 Oct, 2025

India Hospitality + F&B Pro Expo - Goa 2025

Fri, 09 May, 2025 - Sun, 11 May, 2025

Smart Home Expo 2025

Thu, 08 May, 2025 - Sat, 10 May, 2025

CPHI & PMEC China 2025

Tue, 24 Jun, 2025 - Thu, 26 Jun, 2025

International Crop Science Conference and Exhibition 2025

Tue, 10 Jun, 2025 - Wed, 11 Jun, 2025

WORLD OF HOSPITALITY EXPO 2025

Thu, 12 Jun, 2025 - Sat, 14 Jun, 2025

MachAuto 2025

Fri, 25 Jul, 2025 - Mon, 28 Jul, 2025

Asia Labex 2025

Wed, 11 Jun, 2025 - Fri, 13 Jun, 2025

Popular Categories