- Tradeindia

- Ribbon Blender

- Ribbon Blender Mixer

Ribbon Blender Mixer

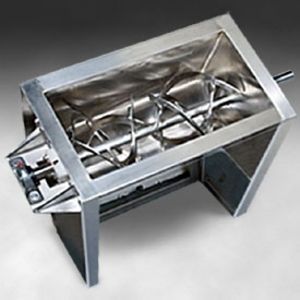

(411 products)Ribbon Blender - Stainless Steel, High Capacity 500 Liters , Efficient Mixing Performance

MOQ1 Number

Product DescriptionRibbon Blender

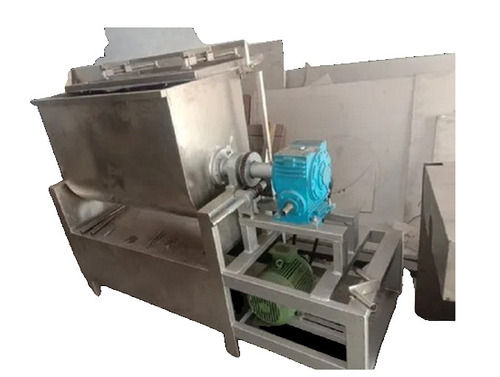

Automatic Innovative Stainless Steel Horizontal Ribbon Blender For Industrial Use

Price: 86000 INR/Unit

MOQ1 Unit/Units

Colormetallic grey

MaterialSS 316

Capacity50-5000 Liter/day

ComputerizedYes

Automatic GradeAutomatic

Shape of TankRectangular

Innovative Engineering Works

Ahmedabad

Super Bonanza

Super Bonanza4 Years

Super Premium

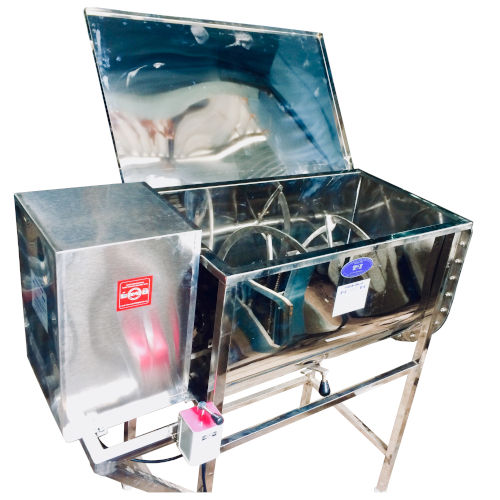

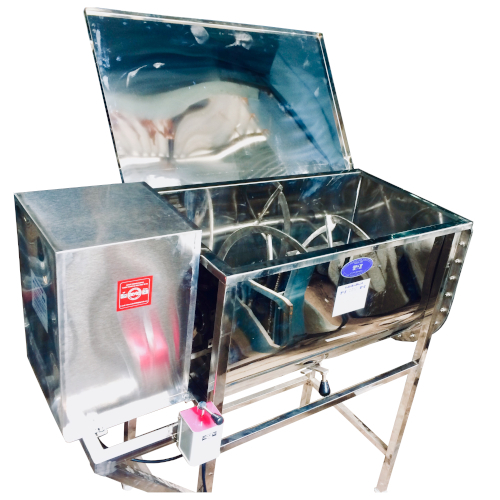

Super PremiumRibbon Blender - Stainless Steel, 500 Liters Capacity | High-Efficiency Mixing, Ideal for Bulk Ingredients

Price: 45000 INR

Product DescriptionRibbon Blender

Zigma Machinery & Equipment Solutions

Coimbatore

Super Bonanza

Super Bonanza14 Years

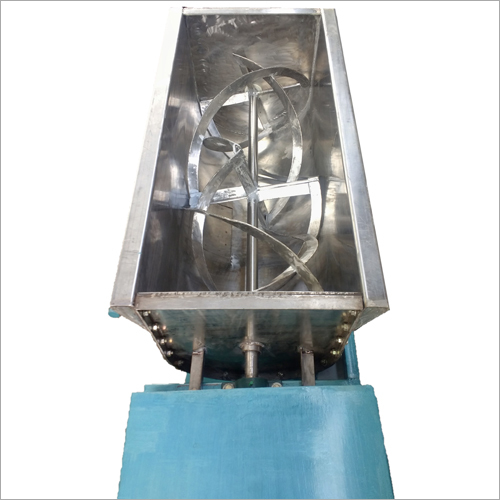

Reaction Blender - Versatile Design for Dry Stage Processes, Temperature-Controlled Accessories for Food, Pharma, and Chemical Applications

Product Description\015\012 The design of the Reaction blender also makes suitable to \015\012 dry stage reaction for the application such as starch, gum \015\012 and cellulose derivatives. We also offer a

Ultra Febtech Private Ltd.

Ahmedabad

4 Years

Super Premium

Super PremiumRibbon Blender - High-Quality Stainless Steel, Smooth Operation & Long Service Life

Price: 45000 INR/Unit

MOQ1 Unit/Units

Supply Ability1 Per Month

Delivery Time3-2 Week

Sample AvailableYes

P-square Technologies

Pune

16 Years

Super Premium

Super PremiumRibbon Blender Mixer Machine

Price: 40000 INR/Piece

MOQ1 Piece/Pieces

TypeRibbon Blender Mixer Machine

MaterialStainless Steel

Automatic GradeAutomatic

Parul Engineering Private Limited

Pune

3 Years

Super Premium

Super PremiumAutomatic Industrial Stainless Steel Ribbon Blender Mixer

Price: 250000 INR/Unit

MOQ1 Unit/Units

ColorGrey

TypeRibbon Blender Mixer

MaterialStainless Steel

ComputerizedNo

Automatic GradeAutomatic

Drive TypeElectric

Magna Tronix

Chennai

4 Years

Ribbon Blender Machine - Automatic Grade , Computerized with Warranty

Price: 150000 INR/Unit

MOQ1 Unit/Units

ComputerizedYes

Automatic GradeAutomatic

WarrantyYes

Fans Bro Erectors

Vasai

19 Years

Ribbon Blender Mixer Machine 100 Kg - Feature: High Efficiency

Price: 210000 INR/Piece

MOQ10 Piece/Pieces

ColorOther, Silver

Product TypeRibbon Blender Mixer Machine 100 kg

General UseIndustrial

MaterialStainless Steel

TypeFood Processors

ComputerizedNo

Mnt Industries

Indore

10 Years

Ribbon Blender Mixer - U-Shaped Trough Design, 40-100% Capacity Agitator Efficiency

Product DescriptionWe are a prominent firm engaged in manufacturing and supplying of Ribbon Blender Mixer in Mumbai, Maharashtra, India. Ribbon Blender consist of a U-shaped horizontal trough and a specially fabricated ribbon agitator. A ribbon agitator consists of a set of inner and outer helical blades.Ribbon agitat

Double Ribbon Blender with Strong Construction

Product DescriptionWe are the notable manufacturer and supplier of Ribbon Blender Machine\302\240as per the application requirements of the clients. This commercial mixer is designed for homogeneous and efficient mixing of variegated formulations and ingredients. It is capable of mixing the smallest quantity of ingred

Thirumalai Industries

Coimbatore

13 Years

Industrial SS Ribbon Blender

Price: 150000 INR/Unit

MOQ1 Unit/Units

FOB PortMudra Port

Payment TermsCash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

Supply Ability10 Per Month

H K Industries

Ahmedabad

2 Years

Semi Automatic Ribbon Blender Mixer

MOQ1 Number

FOB PortAhmedabad

Payment TermsCash in Advance (CID), Cheque, Cash Advance (CA)

Packaging DetailsWooden Box

Allmach Pharma Machinery Private Limited

Ahmedabad

8 Years

Top Rated Products

Automatic Innovative Stainless Steel Horizontal Ribbon Blender For Industrial Use

Innovative Engineering Works

Ribbon Blender - Stainless Steel, 500 Liters Capacity | High-Efficiency Mixing, Ideal for Bulk Ingredients

Zigma Machinery & Equipment Solutions

Ribbon Blender - High-Quality Stainless Steel, Smooth Operation & Long Service Life

P-square Technologies

Ribbon Blender Mixer - U-Shaped Trough Design, 40-100% Capacity Agitator Efficiency

Bombay Pharma Equipments Pvt. Ltd

FAQs Related to Ribbon Blender Mixer

Semi-Automatic Industrial Ribbon Mixer

Price: 200000 INR/Unit

MOQ1 Unit/Units

TypeRibbon Mixer

MaterialSteel

Automatic GradeSemi-Automatic

Pledge International

Ahmedabad

4 Years

Industrial Ribbon Blender Mixer Plant - Automatic Grade: Semi-Automatic

Price: 150000.00 INR/Unit

MOQ1 Unit/Units

MaterialStainless Steel

Automatic GradeSemi-Automatic

Cooling SystemAir Cooling

An Engineering

Hyderabad

3 Years

JCT Stainless Steel Horizontal Ribbon Mixer - 50-5000 Liter Capacity, 4000-110000 Watt Power, Water Cooling System | Versatile Mixing for Powders and Granules with Reliable Pneumatic Flap Valve Discharge

Price Trend: 2000.00 - 30000.00 USD ($)/set

MOQone set

Typemixing

MaterialSS304/SS316

Capacity50-5000 Liter (L)

ComputerizedNo

Automatic GradeAutomatic

Cooling SystemWater Cooling

Foshan Jct Machinery Co., Ltd.

Foshan

1 Years

Semi-Automatic Heavy Duty Industrial Ribbon Blender

Price: 50000 INR/Unit

MOQ1 Number

Materialstainless steel 304 food grade

ComputerizedNo

Automatic GradeSemi-Automatic

Cooling SystemAir Cooling

Pharma Packaging Technology

Thane

15 Years

Instant Mixes Making Machine - Capacity: Upto 1000 Kg/Hr

Price: 500000.00 INR/Unit

MOQ1 Unit/Units

Product TypePremixes Machine

General UseCommercial, Industrial

MaterialStainless Steel

Capacityupto 1000 Kg/hr

Weight (kg)1000 Kilograms (kg)

ComputerizedYes

Tile Adhesive Mixture - Automatic Grade: Semi-Automatic

Price: 200000 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

TypeRibbon Blender Mixer

MaterialMild Steel

Capacity1000 Kg/hr

ComputerizedNo

Automatic GradeSemi-Automatic

Ribbon Blender Mixer - Mild Steel, Semi-Automatic | Available in Different Sizes, Blue/Silver Finish

Price: 60000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue/Silver

TypeRibbon Blender Mixer

MaterialMild Steel

Automatic GradeSemi-Automatic

SizeDifferent Available

Ribbon Blender - Mild Steel & Stainless Steel | 1000 kg Capacity, 10 to 15 HP Motor, High Efficiency, Low Maintenance, Automatic Design

Price Trend: 500000.00 - 5000000.00 INR/Unit

MOQ1 Unit/Units,

TypeRibbon Blender

MaterialMild Steel,Stainless Steel

Automatic GradeAutomatic

Pratham Engineering

Mira Bhayandar

14 Years

Semi-Automatic Ribbon Blenders

Price: 22000 INR/Unit

MOQ1 Unit/Units

MaterialSteel

Capacity100 to 8000 Kg/hr

ComputerizedNo

Automatic GradeSemi-Automatic

Voltage110/220/380/415 Volt (v)

Frequency (MHz)50/60 Hertz (HZ)

Jas Enterprise

Ahmedabad

21 Years

Ribbon Blender - Stainless Steel, 5-1000 Kg/hr Capacity, Semi-Automatic Control | Reliable for Food, Pharma, and Chemical Industries, 1-Year Warranty

Price Trend: 95000.00 - 555000.00 INR/Unit

MOQ1 Unit/Units

TypeTablet Pressing Machine

MaterialStainless Steel

Capacity5 - 1000 Kg/hr

ComputerizedNo

Control ModeSemi-Automatic

Voltage440 Volt (v)

Prime Machinery

Ahmedabad

8 Years

Industrial Ribbon Blenders - Automatic Grade: Semi-Automatic

Price Trend: 74000.00 - 420000.00 INR/Piece

MOQ1 Unit/Units

TypePowder to powder mixer, powder to liquid mixer

MaterialStainless Steel

CapacityAs per Requirement Kg/hr

ComputerizedNo

Automatic GradeSemi-Automatic

Power(W)As per Requirement Statampere (sA)

Bharati Udhyam

Indore

11 Years

Ribbon Blender Mixer - Color: Red

Price: 285000 INR/Piece

MOQ1 Piece/Pieces

ColorRed

Product TypeOther, Ribbon Blender Mixer

Power SourceElectricity

Warranty1 Year

Production Capacity1000 Kg/hr

Usage & ApplicationsIndustrial

Kalsi Industries

Bathinda

4 Years

Ribbon Blender - Stainless Steel, 1000 Liters Capacity | High Efficiency Mixing, Durable Design

Price: 450000 INR/Piece

MOQ10 Piece/Pieces

Product DescriptionRibbon Blender

Stainless Steel Semi-Automatic Ribbon Blender Mixer Machine

Price: 70000 INR/Unit

MOQ10 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Cooling SystemAir Cooling

SizeDifferent Available

WarrantyYes

A.r. Engineering

Indore

3 Years

Namkeen Mixer Or Ribbon Blender - Capacity: 80/100/120/150 Kg/Batch Kg/Hr

Price: 140000.00 INR/Piece

MOQ1 Unit/Units

ColorOther

Product TypeSemi Automatic

TechnologyOther

MaterialStainless Steel

Power SourceElectricity

Operating TypeAutomatic

Gungunwala Food Equipment Pvt. Ltd.

Ahmedabad

15 Years

Ribbon Blender - Color: Gray

Price: 500000 INR/Unit

MOQ1 Unit/Units

ColorGray

Product TypeRibbon Blender

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

AutomaticYes

Esteem Engineers

Mumbai

3 Years

Latest from Ribbon Blender Mixer

Explore More Cities

Ready To Ship Ribbon Blender Mixer

Ribbon Blender Mixer - Design, Applications and Suppliers

One of the most adaptable, affordable and widely used mixers for dry solids in all process industries, from general chemicals to food, pharmaceuticals, agrochemicals and polymers, is the ribbon blender.

Ribbon Blenders are the best choice for blending most solids and thin pastes. Blending is effective and economical thanks to the interaction of the inner and outer ribbons.

To create the mixing action, the double ribbon mixer design rotates the solids while simultaneously moving them in two directions. The outer ribbons move the solids towards the centre of the trough and the inner ribbons move the solids towards the ends of the trough. The outer ribbons direct the discharged solids towards the central discharge valve.

The ribbon mixers will continue to operate at approximately 25% of full capacity. The back and forth mixing activity will continue as long as both the inner and outer ribbon flights are covered.

High speed lump agitators mounted through the side wall of the trough can be used to break up lumps and agglomerates.

Advantages of Using a Ribbon Blender Mixer

- Multifunctional: The benefits of a ribbon blender are endless. Such adaptable equipment is useful in a wide range of industries, including food, cosmetics, agriculture and pharmaceuticals. It is also incredibly easy to use for staff who need to mix heavy substances quickly. It is a time-saving tool that quickly guarantees perfect results. No matter how messy the ingredients are, this machine will produce excellent results.

- Fast response: High shear speeds provide fast ingredient mixing and smooth output. In addition, the robust construction of the ribbon blender ensures that no ingredients leak out during mixing. As a result, you can get the job done before the deadline without making any mistakes.

- Robust and hygienic: Mixing different materials can cause contamination, which can spread dangerous substances that can be harmful to your health, causing infections and other ailments. With this in mind, the ribbon blender ensures a high level of cleanliness by preventing product cross-contamination. The stainless steel construction of this mixer also makes it durable.

- Suitable for both dry and wet use: The ribbon blender machine is suitable for both dry and wet users as it is built to a high standard of craftsmanship. The mixers are also manufactured with both ends closed.

- Fits easily into tight spaces: The mixer has a compact design that fits easily into tight spaces. This means that you don't need to create a dedicated space for your equipment to mix industrial materials.

Ribbon Blender Specification

Ribbon Blenders are two-part powder mixers with a central shaft. Helical ribbons inside and outside their mixing medium can move both inwards and outwards. They pick up materials from the sides and place them inside the ribbons. A continuous mixing pattern must be created by blending the back and forth folding motion of the materials.

The machine's belts are separated from each other by the machine's walls. To ensure that the product continues to accumulate on both sides, manufacturers sometimes produce them with soft scrapers. The belt drive of the motor and gearbox is the underlying drive mechanism for power transmission. It uses a system of pulleys and flexible belts to achieve speed.

Direct drive gearboxes, which use a motor to match the gearbox unit, have become popular with some manufacturers. This frees equipment owners from concerns about ongoing maintenance costs. However, the owner of a ribbon mixer will be aware of the required capacity of the machine.

It's important to be aware of the different product densities when mixing. To ensure effective mixing, you also need to be aware of the mixer capacity and motor power required. With a bulk density of 35 lbs/ft3, many designs will often give excellent results. However, you need to be aware of the need for powerful motors and gear ratios when starting the batch mixing process.

Ribbon Mixer Precautions

Ribbon mixer safety measures

The ribbon powder mixer, like any coin, has two sides, with advantages and disadvantages. On the other hand, there are solutions available to remedy the problems. For example, use the lower bulk density if you have a ribbon blockage. The advantages of the mixer over the belt outweigh its disadvantages, making it a practical, easy to use and time saving mixing device for virtually any industry.

Despite the simple instruction manual, some people still find it difficult to use, although we have included a step-by-step guide to operating the Ribbon Mixer. However, it will enable you to understand how things should work.

However, you will need to do the following:

Personal protective equipment (PPE) such as gloves, goggles, masks, etc. should always be worn.

- Check the chute again, it must be closed.

- Connect the switch, then switch on.

- Open the lid of the mixing vessel by hand.

- All raw materials should be added to the mixing hopper first.

- Try to fill the mixing tank to 70% of its capacity. It will be overfilled if you exceed the recommended ratio.

- Close the lid.

- Set the time to suit your needs.

- Activate the process

- Within 15 to 25 minutes your machine will start and finish mixing. This is how long it usually takes

- for the components to mix thoroughly.

- Press the start button to open the discharge chute.

- Press the Stop button.

Ribbon Blender Machine Uses

An industrial ribbon blender or ribbon mixer is used in manufacturing plants. It is useful for mixing substances with many particles. It's also important to combine these components evenly. This mixer has mixing blades at different angles and a shaft. The blades are designed to wrap around the shaft like metal bands, making it easy to move different components in different directions at the same time. This machine can be used by both food and pharmaceutical manufacturers.

For example, the iPharMachine's horizontal ribbon mixer is particularly user-friendly due to its small size. It can be built to fit into the limited overhead space. It works efficiently and takes less time to achieve a uniform result. It has a fast-rotating stirrer that can mix powders of different sizes and densities. The ribbon blender is a versatile product that can be used in any laboratory as it is sharp enough to mix around 90% of materials, including cosmetics and pharmaceuticals.

Ribbon Blender Mixer Price List

Product Name | Expected Price |

|---|---|

| Industrial Ribbon Blender | 180000 |

| Ribbon Blender Mixer | 120000 |

| Ribbon Blender Mixer | 150000 |

| Industrial Ribbon Blender Mixer | 150000 |

| Ribbon Mixer Blender | 50000 |

| Industrial Ribbon Blender | 50000 |

| Ribbon Blender Mixer Machine | 280000 |

| Powder Mixer Ribbon Blender | 500000 |

| Industrial Ribbon Blender Machine | 600000 |

| Ribbon Blender Mixer Machine | 180000 |

This Data was Last Updated on 2025-04-18

Ribbon Blender Mixer Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Jas Enterprise Ahmedabad, India | 21 Years |

Fans Bro Erectors Vasai, India | 19 Years |

P-square Technologies Pune, India | 16 Years |

Pharma Packaging Technology Thane, India | 15 Years |

Gungunwala Food Equipment Pvt. Ltd. Ahmedabad, India | 15 Years |

Zigma Machinery & Equipment Solutions Coimbatore, India | 14 Years |

Pratham Engineering Mira Bhayandar, India | 14 Years |

Thirumalai Industries Coimbatore, India | 13 Years |

Bharati Udhyam Indore, India | 11 Years |

Mnt Industries Indore, India | 10 Years |

Upcoming Tradeshows

FoodTech Kerala 2025

Thu, 22 May, 2025 - Sat, 24 May, 2025

Copper China 2025

Wed, 09 Jul, 2025 - Fri, 11 Jul, 2025

INDIAN ICE CREAM CONGRESS & EXPO 2025

Mon, 06 Oct, 2025 - Wed, 08 Oct, 2025

India Hospitality + F&B Pro Expo - Goa 2025

Fri, 09 May, 2025 - Sun, 11 May, 2025

Smart Home Expo 2025

Thu, 08 May, 2025 - Sat, 10 May, 2025

CPHI & PMEC China 2025

Tue, 24 Jun, 2025 - Thu, 26 Jun, 2025

International Crop Science Conference and Exhibition 2025

Tue, 10 Jun, 2025 - Wed, 11 Jun, 2025

WORLD OF HOSPITALITY EXPO 2025

Thu, 12 Jun, 2025 - Sat, 14 Jun, 2025

MachAuto 2025

Fri, 25 Jul, 2025 - Mon, 28 Jul, 2025

Asia Labex 2025

Wed, 11 Jun, 2025 - Fri, 13 Jun, 2025

Popular Categories