Round Bars

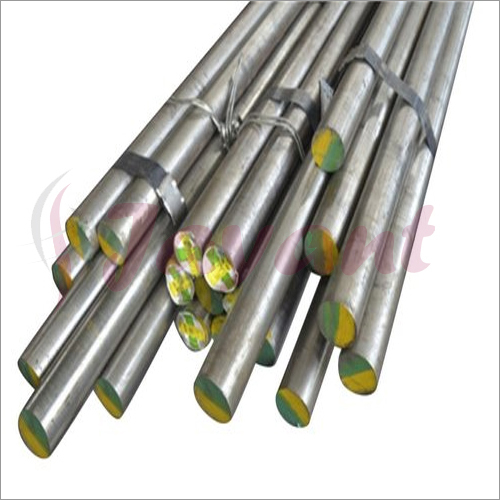

(6310 products)Stainless Steel Round Bars - 1 mm to 300 mm Size Range | Powder Coated, Corrosion Resistant, Impact Resistant, Homogenous Surface

Price: 160 INR/Kilograms

MOQ100 Kilograms/Kilograms

GradeIndustrial

MaterialSS

FinishPowder Coated

TypeStainless Steel Round Bars

ApplicationIndustrial

Niko Steel And Engineering Llp

Mumbai

Super Bonanza

Super Bonanza23 Years

High Speed Steel Bar Application: Industrial

Price Trend: 700.00 - 3500.00 INR/Kilograms

MOQ1 Kilograms/Kilograms

ApplicationIndustrial

FinishBright, Black

Specific UseCutter, Tools

StandardAISI

DiameterVarious from 3mm to 250mm Millimeter (mm)

TypeBar, Round, Rod

Jayant Impex Pvt Ltd

Mumbai

4 Years

Super Premium

Super PremiumAluminum Bronze Round Bars - Industrial Grade, Polished Finish | High Tensile Strength, Anti-Friction, Corrosion Resistant

Price: 250.00 INR/Kilograms

MOQ500 Kilograms/Kilograms

MaterialAluminium

FinishPolioshed

ApplicationManufacturing,Construction

GradeIndustrial

TypeAluminum Bronze Bars

Govind Metal Co.

Ahmedabad

Super Bonanza

Super Bonanza18 Years

Ss 316 Round Bar - Application: Construction

Price: 350 INR/Kilograms

MOQ500 Kilograms/Kilograms

ShapeRound

GradeSS 316

ApplicationConstruction

MaterialStainless Steel

Diameter5mm -20mm Millimeter (mm)

FinishPolished

Shyam Metals & Alloys

Mumbai

5 Years

Super Premium

Super PremiumP20 Steel Round Bar Application: Construction

Price Trend: 250.00 - 300.00 INR/Kilograms

MOQ10 Kilograms/Kilograms

MaterialSteel

GradeP20

ApplicationConstruction

FinishGalvanized

TypeP20 Steel Round Bar

Vishal Steel Industries

Mumbai

Super Bonanza

Super Bonanza15 Years

Mild Steel Round Bar - Application: Industrial

Price: 55000.0 INR/Ton

MOQ10 Ton/Tons

ApplicationIndustrial

MaterialSteel

GradeIndustrial

Hico Multifin Products Pvt Ltd

Kolkata

Super Bonanza

Super Bonanza6 Years

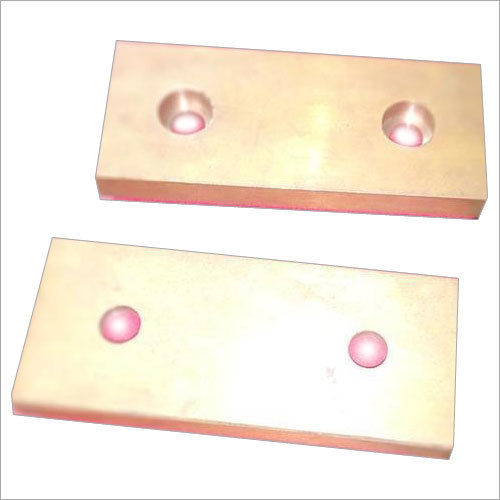

Sintered Bronze Bars - Application: Industrial

Price: 25545 INR/, Piece

MOQ1 , Piece/Pieces

FinishFully Finishes

TypePlates

GradeIS3980

Length50 - 250 Millimeter (mm)

ApplicationIndustrial

MaterialBronze

Oilite Industries

Kolkata

8 Years

Die Steel Round Bar - 8-32 mm Diameter, 3-18 Meter Length | High-Quality Alloy Steel, Ideal for Die and Mold Applications

Price: 140.00 INR/Kilograms

MOQ200 Kilograms/Kilograms

ApplicationConstruction

Length3-18 Meter (m)

Diameter8 - 32 Millimeter (mm)

MaterialAlloy Steel

Ventura Alloy And Steels Private Limited

Mumbai

9 Years

Super Premium

Super PremiumNickel And Copper Alloy Bar Application: Industrial

MOQ50 Kilograms/Kilograms

FinishMirror Finishing

Length10 to 20 Foot (ft)

MaterialNickel And Copper

TypeBar

ApplicationIndustrial

Shree Rajlaxmi Forge

Mumbai

7 Years

Silver Stainless Steel 310 Round Bar

Price: 550 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorSilver

Product NameStainless Steel Products

Steel TypeStainless Steel

Steel Product TypeSteel Bars

Grade310

ApplicationOther, Manufacturing

Bhavya Stainless Private Limited

Mumbai

4 Years

Mild Steel Round Bar - Corrosion Proof, Excellent Quality, Fine Finishing, Long Life, Optimum Performance

ApplicationIndustrial

Indian Iron & Steel Suppliers

Kolkata

17 Years

Corrosion Resistant Fiber Bar - Application: Industrial

Price: 200 INR/Kilograms

MOQ1000 Kilograms/Kilograms

Material GradeA

Length3 Meter (m)

ShapeRound

TypeCorrosion Resistant Fiber Bar

ApplicationIndustrial

Diameter6 Millimeter (mm)

Plurimo Pultrusion And Composite Private Limited

Ahmedabad

4 Years

Hot Roller Steel Round Bar

Product DescriptionHot roller steel round bar Gr. GCr15 ,SAE52100, SUJ2, EN31,100Cr6 and so on . \015\012\015\012Purpose/application : row material of Bearing , Machinery parts , car parts ect . \015\012Size range : 20mm - 300mm \015\012With MILL TEST REPORT . \015\012Min. Qty : 10 Tons

Cixi Hoto Metallic Product Co.,ltd

Ningbo

Super Bonanza

Super Bonanza11 Years

Galvanized 42Crmo4 Round Bar

MOQ10 Kilograms/Kilograms

GradeMulti

StandardHigh

FinishGalvanized

MaterialAlloy steel

TypeSteel bar

Specific UseConstruction

Dmson's Metal Pvt.ltd.

Mumbai

2 Years

Gunmetal Round Bars - Diameter: 4 To 200 Millimeter (Mm)

Price Trend: 10.00 - 100.00 INR/Piece

MOQ10 Piece/Pieces

ShapeRound

FinishPolished

TechniqueHot Rolled

MaterialGunmetal

Diameter4 to 200 Millimeter (mm)

UsageConstruction

Steel Mart

Mumbai

19 Years

Polished Inconel Round Bars

Price: 2000 INR/Kilograms

MOQ50 Kilograms/Kilograms

MaterialStainless Steel

Length6 Meter (m)

FinishPolished

Specific UseConstruction

TypeInconel Round Bars

Imi Special Steels And Alloys

Mumbai

3 Years

Mild Steel Round Bar - Stainless Steel, Polished Finish | First Class Grade, Normal Standard, Industrial Application

Price: 65 INR/Kilograms

MOQ2 Ton/Tons

StandardNormal

ApplicationIndustrial

FinishPolished

MaterialStainless Steel

GradeFirst Class

Shubh M L Shah Sons Steel Private Limited

Navi Mumbai

3 Years

EN8 Round Bar - Medium Carbon Steel, Diameter 5-50mm, Length 3m, Coated Finish | High Strength, Excellent Creep Resistance, Ductile Flexibility

Price Trend: 50.00 - 100.00 INR/Kilograms

MOQ100 Kilograms/Kilograms

ApplicationConstruction

Length3 Meter (m)

FinishCoated

Diameter5-50 Millimeter (mm)

MaterialCarbon Steel

Aakar Pipe & Tubes

Mumbai

13 Years

Nilo 76 Round Bar Application: Manufacturing

Price: 2400 INR/Kilograms

MOQ100 Kilograms/Kilograms

FinishPolished

Grade76

Length3m,6m,12m Meter (m)

MaterialStainless Steel

TypeNilo 76 Round Bar

ApplicationManufacturing

Jai Jirawal Metal & Alloys

Mumbai

10 Years

Titanium Round Bars - Made from Finest Titanium, High Strength & Rust Resistance, Excellent Finish

Product DescriptionWe are among the prominent names in the industry, engaged in manufacturing and supplying of Titanium Round Bars in Mumbai, Maharashtra, India. These titanium round bars are made with the latest tools & machinery along with finest titanium. We examine these titanium round bars on quality factors for

Acero Engineering Company

Mumbai

4 Years

Stainless Steel Round Bars - Solid Surface, Galvanized Finish, Higher Strength | Ruggedly Constructed, Corrosion and Rust Resistant, Heavy-Duty Quality

Price: 180 INR/Kilograms

MOQ500 Kilograms/Kilograms

ApplicationIndustrial

SizeComes in various sizes

ShapeRound

Specific Usefor Industrial

FinishPolished

TechniqueHot Rolled

Righton Impex

Mumbai

11 Years

High Grade Round Bars

MOQ5 Ton/Tons

FinishPolished

GradeDifferent Available

ApplicationIndustrial, Construction

TypeHigh Grade Round Bars

Sarthak Metals

Faridabad

3 Years

316L Stainless Steel Round Bars - 3 Meters Length, Polished Finish for Industrial Applications

Price: 255 INR/Kilograms

MOQ100 Kilograms/Kilograms

Length3 Meter (m)

ApplicationIndustrial

FinishPolished

MaterialStainless Steel

Type316L Stainless Steel Round Bars

Parmar Steel

Mumbai

2 Years

Aisi 310 Stainless Steel Round Bar Diameter: 2 Inch Inch (In)

Price: 450 INR/Kilograms

MOQ150 Kilograms/Kilograms

Diameter2 inch Inch (in)

MaterialStainless Steel

Length6 Meter (m)

GradeAISI 310

FinishPolished

Parag Steel Corporation

Mumbai

5 Years

Monel Round Bar - Monel Material, ASTM Standard, Galvanized Finish | Industrial Grade, High Durability for Petrochemical Applications

Price: 2000 INR/Kilograms

MOQ1000 Kilograms/Kilograms

TypeMonel Round Bar

FinishGalvanized

StandardASTM

ApplicationIndustrial

MaterialMonel

GradeiNDUSTRIAL

Kalpataru Metal & Alloys

Mumbai

5 Years

Stainless Steel Round Bar 202 Application: Industrial

Price: 270 INR/Kilograms

MOQ100 Kilograms/Kilograms

FinishPolished

GradeFirst Class

MaterialStainless Steel

ApplicationIndustrial

StandardNormal

Mahi Exporters

Mumbai

3 Years

Molybdenum Rods By Pragati Metal Corporation

Price: 7500 INR/Kilograms

MOQ100 Kilograms/Kilograms

Delivery Time10-15 Days

Pragati Metal Corporation

Mumbai

7 Years

Super Premium

Super PremiumSteel Round Bar - Application: Industrial

MOQ1000 Kilograms/Kilograms

ApplicationIndustrial

MaterialSteel

TypeBar

FinishPolished

GradeDifferent available

Ras Multimetals

Mandi Gobindgarh

2 Years

Latest From Round Bars

Ready To Ship Round Bars

What is Round Bars? Application Areas of Round Bars

A long, cylindrical metal bar, Round Bar has many applications in industry and commerce. The most typical use is for shafts. A round bar can be made from a wide variety of metals, including duplex steel, super duplex steel, nickel alloy, alloy steel, stainless steel, carbon steel, inconel, monel, titanium, alloy 20, hastelloy, and more. Steel round bars are used for a wide variety of production tasks. One of the most significant contributions of metallurgy to the development of society and the economy was the invention of stainless steel. There is truth in the adage that "steel" can be found in everyone's life nowadays. This crucial metal, or alloy, has permeated everyday life and the industrial sectors to such an extent that it has become an integral part of the world economy.

Applications of Round bars in different Industries:

- 1. Round bars of varying sizes and materials are now commonly used in the construction of automobile frames and chassis.

- 2. In the construction of trellises, fences, and railings, round bars are frequently employed.

- 3. In the building and engineering industries, steel round bars are a common material.

- 4. Bolts, nuts, screws, washers, and rivets are just few of the many fastener items that call for round bars.

- 5. Oil and Gas Industry Stainless Round Bars

- 6. In the plumbing trade, round bars are used to

- 7. Water pipe round bars are made of steel.

- 8. Useful Stainless Round Bars for the Nuclear Power Industry

The Difference Between Round Bar and Precision Ground Bar

Round Bar

Variations of Round Bars:

1. By Process

Round bar can be produced in three different ways: by hot rolling, by cold drawing, or by forging. Hot rolled bars typically range in size from 5.5mm to 250mm. Common uses for round bars in the 5.5mm to 25mm range include bolts, steel bars, and a wide variety of mechanical parts. Most mechanical components, tube billets, etc., are made from round bar larger than 25 millimeters in diameter.

2. By Chemical Composition

Based on its carbon content (chemical makeup), carbon steel can be divided into three categories: low carbon steel, medium carbon steel, and high carbon steel.

- Low Carbon Steel: The term "mild steel" is also commonly used to describe this material. The carbon content is low (0.10-0.30%) and it may be worked fast (cutting, welding, forging). Used in the production of bolts, chains, rivets, and shafts, among other things.

- Medium-carbon Steel: It falls into the category of carbon steel and typically has a carbon content of 0.25-0.60%. There is also a trace amount of manganese present, between 0.70 and 1.20 percent. Carbon steel can be classified as either "ordinary" or "high-quality," depending on how much attention was paid to its creation. Cutting and hot working talents are top-notch, but welding isn't one of them. The hardness and strength of this steel are more than those of low-carbon steel, but the toughness and plasticity are lower. Both hot-rolled and cold-drawn materials would be used before and after the heat treatment.

- High Carbon Steel: Carbon levels in this steel range from 0.60 to 1.70 percent, and it can be heat treated to increase its hardness. High-carbon steel is used to make a variety of cutting instruments, including drills, reamers, taps, crowbars, and hammers.

Precision Ground Bar

1. Manufacturing Process

In order to create high-quality ground bars, induction hardening is used.

Induction Hardening: It's not a conventional heating method, as the heat is generated through electromagnetic induction rather than direct touch. Steel is placed in a powerful magnetic field, which induces an electrical current in the material and causes it to heat up. The core of the steel remains unchanged and retains all of its original properties. A martensitic structure forms on the steel's surface after it is quenched in oil, water, or a very particular polymer.

2. Potential Uses for Precision-Ground Bar

Widespread use of the precision ground bar can be seen in fields where accuracy is crucial.

- -Drive shafts

- -High-speed motor shafts

- -Laboratory tools

- -Ball bushings

- -Weather measuring devices

- -Pump shafts

In such situations, rapid rotation of the bar is often required. Thus, remarkable straightness is necessary to forestall unintended vibration and bearing wear.

3. Precision Ground Bar Features And Benefits

Precision ground bar is distinguished from other products by three primary features:

- -Heightened sphericity

- -Improved symmetry

- -Variation in diameter within a given tolerance

The Different Types of Construction Round Bar

1 Prestressing Round Bars

All other types of steel bars are not the same as prestressed steel bars, which are based on a unique technique. Here, steel bars are represented by strands, and the Prestressing effect results from their use in a construction frame. One strand of prestressed steel bar might consist of anywhere from two to seven individual wires.

2. Cold Worked Round Bars

The Effects of Cold Temperatures After the hot-rolled bars are further processed, steel bars are produced as another sort of reinforced steel. During a cold-worked process, hot-rolled bars are subjected to a cold working process. Cold working the hot rolled steel bars produces a reinforcing bar. Bars will be subjected to twisting and drawing during the cold working process, which is carried out at room temperature, hence decreasing the ductility of the steel.

3. TMT steel bars

When it comes to steel bars, TMT steel is by far the most popular option in today's modern construction industry. TMT steel has numerous benefits over standard steel bars in addition to its unparalleled tensile strength. TMT steel is resistant to corrosion and earthquakes, as well as being light and simple to put together. TMT steel is the highest quality available because of its superior composition and production method.

In addition, TMT steel bar is available in a number of different qualities, each of which has its own unique characteristics and strength.

4. Hot Rolled Deformed Bars

Hot-rolled deformed bars are widely used in R.C.C. construction, and they are a popular choice for their durability and versatility. These bars are ideal for any building project due to their great tensile strength (about 60000psi). Steel greatly improves the structural integrity of the building. The holt rolling procedure used to produce these steel bars results in surface deformations (known as ribs) that aid in forming a durable bond with the concrete.

Mild Steel Plain Round Bars

This is one of the most basic kinds of steel bars, but it has been utilized for decades in the construction industry.

Unlike other types of bars, which often feature a ribbed structure (thus the name "ribbed" bars), mild steel plain bars have a smooth outer surface and a lower tensile yield strength (which stands at around 40000psi).

Difference Between Round Bars And Reinforcement Bars (Rebars)

Steel Round Bars

1. Simple reinforcing bars are another name for round rebars (PRB).

2. They are round in cross-section and completely straight metal rods. They're perfectly straight and undamaged, with polished surfaces.

3. There is a large variety of round rebars available, both in terms of length and diameter. It's utilized to reinforce other bars, divide mesh in the concrete, and create ligatures when building or repairing structures.

4. Because of their flat ends, round rebars are ideal for joining steel beams, girders, and columns together.

Reinforcement Bars

1. There are many various forms that deformed rebar, or reinforcing bar, can take. It might be shaped like helical bars or corrugated steel.

2. There is a special twist to the bars that allow them to interlock with one another when they are laid side by side in the concrete.

3. All of the ridges or indentations are the same height and are positioned at the same distances from one another over the whole bar.

4. In high-stress applications, such as large-scale commercial and industrial projects, deformed rebars are almost always utilized since they are more expensive but resist slippage better than round rebars.

Which is Strong?

The tensile strength of deformed reinforcing bars is greater, making them more robust. As a result, it is the material of choice for projects like constructing highway overpasses, parking garages, bridges, and tall structures. But bent rebars aren't always preferable. Each construction job has unique requirements, thus the decision between round and deformed rebar must be made on the fly. In most cases, round rebars are less expensive and more affordable, not to mention more accessible and practical.

ISO-approved round bars are the greatest option because they have been shown to last the longest and endure the most abuse. People put their trust in things when they know they will last, thus it's important to only buy certified products from reliable manufacturers and suppliers. Enhanced efficiency is one of the promises made by these new norms.

In addition, it guarantees that you are purchasing only high-quality items from reputable vendors. Better quality and services are an investment in long-term partnerships and should be taken into account by both buyers and sellers.

Supreme Quality Round Bars Available In The Market With Price

Round Bars are available in abundance in the online market. Buyers planning to buy round bars in bulk quantity should check the details by clicking on the product link. They can check the technical specifications, sizes, and price, and supply capabilities of individual sellers.

It is important for the buyers to check certain features before buying round bars. They can also check some specific information, such as MS round bar price list offered by different sellers for their satisfaction. Check the features and details, such as:

a) - diameter of cross-sections

b) - material grade and quality

c) - tensile strength and ductility

d) - technical requirements for specific applications

e) - price

f) - delivery time

g) - available stock

h) - minimum order quantity

Buy Round Bars Online

Round Bars are widely used in different industries. These are known for excellent surface finish, malleability, corrosion resistance, versatility and adaptability. Buying round bars was never easy as it is today. Buyers can check the technical specifications, round bar weight, types, material of construction and other necessary details easily. Buyers can also check the prices offered by different suppliers of round bars online.

There are several variants of round bars from which buyers can choose as per their specific needs:

-Alloy Steel Round Bars

-Ss Round Bar

-En Series Round Bars

-En8 Round Bars

-En45 Spring Steel Round Bars

-Round Mild Steel Bars

-Aluminium Bronze Round Bars

-Ms Round Bar

-Inconel Round Bar

Interested buyers may check the contact details of suppliers available online and send their product orders according to their specific needs.

FAQs: Round bars manufacturers

Q. What is meant by round bars?

Ans. Round bars are cylindrical shape solid rods or shafts used in a variety of applications. These are used in valves, pump shafts, machine tools, dairy equipment, pins, metal parts, machined components, etc.

Q. What are the common types of round bars?

Ans. Common types of round bars include carbon steel, alloy steel, stainless steel, aluminum, and titanium. Each type bars has its own unique features and properties and is used for specific applications.

Q. What is 2205 Duplex Stainless Steel Round Bar?

Ans. Duplex 2205 round bar is an austenitic ferritic stainless steel that has 22 percent chromium, 3 percent molybdenum, and 5 to 6 percent nickel in its alloy. The most popular duplex stainless steel grade is also the strongest, with a yield strength that is twice as high as that of regular austenitic stainless steel.

Q. What does IS standard mean for round bars?

Ans. In the Indian context, IS standard informs about the quality grade of round bars. For example, IS2062 is a standard for ensuring the quality of hot rolled medium and high tensile structural steel.

Q. What is the application of aluminium round bars?

Ans. Aluminium round bars are suitable for bending and forming shapes for structural applications. In other words, aluminium round bars can be bent and formed in specific types of structures.

Q. What is the price of round bars in India?

Ans. Rounds bars’ price in India varies according to the size, dimensions and material grade. An 8mm round bar of 6 meter length will cost around Rs.150 per unit. A 10mm bar of the same length will cost Rs.200.

Q. Where can we buy round bars?

Ans. Round bars can be bought from a trusted B2B market where a comprehensive list of sellers could be registered to offer a variety of choices to the customers.

Q. How are round bars measured?

Ans. Round bars are typically measured by their diameter. The diameter is the distance across the bar at its widest point.

Q. What are the benefits of using round bars?

Ans. Round bars are strong, durable, and versatile. They can be easily cut and shaped to suit a wide range of applications. They also have a low cost, good machinability and easy availability.

READ BLOG:

Manufacturers & Suppliers of Round Bars

Company Name | Member Since |

|---|---|

Niko Steel And Engineering Llp Mumbai, India | 23 Years |

Steel Mart Mumbai, India | 19 Years |

Govind Metal Co. Ahmedabad, India | 18 Years |

Indian Iron & Steel Suppliers Kolkata, India | 17 Years |

Vishal Steel Industries Mumbai, India | 15 Years |

Aakar Pipe & Tubes Mumbai, India | 13 Years |

Cixi Hoto Metallic Product Co.,Ltd Ningbo, China | 11 Years |

Righton Impex Mumbai, India | 11 Years |

Jai Jirawal Metal & Alloys Mumbai, India | 10 Years |

Ventura Alloy And Steels Private Limited Mumbai, India | 9 Years |

Popular Products