- Tradeindia

- Bright Bars

- Stainless Steel Bright Bars

Stainless Steel Bright Bars

(561 products)Stainless Steel Bright Bars By Niko Steel and Engineering Llp

Price: 160 INR/Kilograms

MOQ100 Kilograms/Kilograms

Supply Ability100 Per Day

Delivery Time1 Week

Stainless Steel Bright Bar By Pragati Metal Corporation

Price: 200 INR/Kilograms

MOQ100 Kilograms/Kilograms

Delivery Time10-15 Days

ISO 5832-9 Stainless Steel

Price: 500 INR/Kilograms

MOQ1 Kilograms/Kilograms

LengthAny

ApplicationIndustrial

SS 316L Bright Bar - Stainless Steel 316L, Polished Silver Finish | High Corrosion Resistance, Ideal for Industrial Applications

Price: 400 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorSilver

Product NameStainless Steel Products

Steel TypeStainless Steel

Steel Product TypeSteel Bars

Grade316L

SurfacePolished

Bhavya Stainless Private Limited

Mumbai

Super Seller

Super Seller4 Years

Stainless Steel Bars By Nascent Pipes & Tubes

Price: 1 INR/Kilograms

MOQ100 Kilograms/Kilograms

FOB PortMumbai

Payment TermsCash in Advance (CID), Cheque

Supply Ability1 Per Day

Stainless Steel Bright Bars - Color: Silver

Price Trend: 10.00 - 100.00 INR/Piece

MOQ10 Piece/Pieces

GradeIndustrial

SizeStandard

ColorSilver

UsageIndustrial

TypeStainless Steel Bright Bars

MaterialSS

ARORA Bright Bars

MaterialSteel

FinishBright

ShapeRound

LengthVariable

DiameterCustomizable

TolerancePrecise

Stainless Steel Round Bar Grade: First Class

Price: 250 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorBright, Black

Product NameStainless Steel Products

Steel TypeStainless Steel

Steel Product TypeOther

Grade304, 304L, 316, 316L, 904L

Thickness1 to 300 Millimeter (mm)

S.S.Bright Bar

Price: 155 INR/Kilograms

MOQ500 Kilograms/Kilograms

Supply Ability100000 Per Month

Delivery Time1 Days

Sample AvailableYes

Stainless Steel Bright Bars By Parag Steel Corporation

Supply Ability100 Per Week

Delivery Time1 Week

Main Domestic MarketAll India

Stainless Steel Bar - 17-4 PH, Length 3660-6000 mm | Premium Quality, Anti-Rust Properties, Tested for Optimum Performance

Price: 200 INR/Kilograms

MOQ100 Kilograms/Kilograms

TypeStainless Steel Bar

ApplicationIndustrial

MaterialStainless Steel

Grade17-4 PH

Length3660-6000 Millimeter (mm)

Stainless Steel Bright Flat Bar - Application: Automotive Parts

Price: 60 INR/Kilograms

MOQ500 Kilograms/Kilograms

ShapeFlat

Applicationautomotive parts, machinery parts

Surface TreatmentPolishing

Length3 to 6 mtr Meter (m)

Product TypeALUNIMUM FINISH AND MIRROR FINISH SURFACE

Colorna

Top Rated Products

SS 316L Bright Bar - Stainless Steel 316L, Polished Silver Finish | High Corrosion Resistance, Ideal for Industrial Applications

Bhavya Stainless Private Limited

FAQs Related to Stainless Steel Bright Bars

Who are the top stainless steel bright bars manufacturers in India?

- Niko Steel And Engineering Llp

- Steel Mart

- British Super Alloys Pvt. Ltd.

- Nascent Pipes & Tubes

- Righton Impex

- Devasya Engineers

- Pragati Metal Corporation

- Maharashtra Metal (india)

- Harshvijay Exim Opc Private Limited

- Dnr Alloys

Which cities have the largest number of stainless steel bright bars suppliers?

- Mumbai

- Chennai

- Kolkata

- Pune

- Delhi

- Bengaluru

- Hyderabad

- Ahmedabad

- Faridabad

- Ghaziabad

- Ludhiana

- Vadodara

- Indore

- Rajkot

- Raipur

- Bhavnagar

- Gurugram

- Howrah

- Nagpur

- Kolhapur

What is the price range for stainless steel bright bars offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| Shree Krishna Iron and Steel | INR | Steel Bright Bar | 80 |

| STAR DEEP METAL | INR | Stainless Steel Bright Bar | 350 |

| NIKUNJ STEEL CENTRE | INR | Stainless Steel Bright Bar | 350 |

| Som Shanti Steels | INR | 321 Stainless Steel Bright Bar | 350 |

| MAA VAISHNO BRIGHT BAR & STEEL | INR | Stainless Steel Bright Bars | 270 |

How many trusted sellers are available for stainless steel bright bars?

- NIKO STEEL AND ENGINEERING LLP

- PRAGATI METAL CORPORATION

- JAYANT IMPEX PVT LTD

- NASCENT PIPES & TUBES

- STEEL MART

- ARORA IRON AND STEEL TRADERS

- Metline Overseas

- RIGHTON IMPEX

- PARAG STEEL CORPORATION

- MAHARASHTRA METAL (INDIA)

- DEVASYA ENGINEERS

- EXCEL METAL & ENGG INDUSTRIES

- KAMDHENU STEEL

- BRITISH SUPER ALLOYS PVT. LTD.

- Technolloy Inc.

- HBM-ALLOY-INC

- JICON STEEL INDIA

- DNR ALLOYS

- INOX PIPES AND FITTING INDIA

- STAR DEEP METAL

- KAVIRAJ METAL INDUSTRIES

- DEV METAL INDUSTRIES

- Som Shanti Steels

What is the minimum order quantity for stainless steel bright bars?

Do listed companies have registration & certifications?

- PRAGATI METAL CORPORATION

- Metline Overseas

- DEVASYA ENGINEERS

- KAMDHENU STEEL

- BRITISH SUPER ALLOYS PVT. LTD.

- NANDISHWAR STEEL

What is the get latest price feature?

What types of payment methods are accepted by the stainless steel bright bars suppliers?

Stainless Steel Bright Bar Application: Industrial

Price: 150 INR/Kilograms

MOQ1000 Kilograms/Kilograms

ApplicationIndustrial

TypeRound Bars

GradeDifferent Available

FinishPolished

MaterialSS

410 Stainless Steel Bright Bar Application: Door & Window

Price: 365 INR/Kilograms

MOQ50 Kilograms/Kilograms

ColorGrey

Product NameStainless Steel Products

Steel TypeStainless Steel

Steel Product TypeSteel Bars

Grade410

Thickness0.1 mm - 100 mm Millimeter (mm)

Ss 304 Export Bright Cg Round Bar Application: Oem

Price: 135 INR/Kilograms

MOQ2000 Kilograms/Kilograms

Techniquepeeling and CG

Grade304

ProcessingBuffing

Length6 Meter (m)

Diameter16 to 130 Millimeter (mm)

Tolerance0.05 Millimeter (mm)

British Super Alloys Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller13 Years

Stainless Steel Bright Bar - Application: Industrial

Price: 250 INR/Kilograms

MOQ100 Kilograms/Kilograms

Material GradeA

Diameter3-100 Millimeter (mm)

ShapeRound

Length3 Meter (m)

UsageIndustrial

Surface FinishPolished

Stainless Steel 304 Round Bar - 6-36m Length , Superior Durability & Corrosion Resistance

Price Trend: 10-1000 INR/Piece

MOQ50 Piece/Pieces

Product NameStainless Steel Products

Steel TypeStainless Steel

Steel Product TypeSteel Bars

Grade304

ShapeBar

Steel StandardAISI

Harshvijay Exim Opc Private Limited

Ahmedabad

Premium Seller

Premium Seller7 Years

Stainless Steel Round Bright Bar - Corrosion Resistant, Solid Build, Preferred Quality for Industrial Uses

Price: 200 INR/Kilograms

MOQ10000 Kilograms/Kilograms

ApplicationFor Industrial Uses

ShapeRound

ColorSilver

Product TypeBright Bars

GradeVary

Jain Metal Impex

New Delhi

Premium Seller

Premium Seller3 Years

321 Stainless Steel Round Bar - Application: Construction

Price: 350 INR/Kilograms

MOQ50 Kilograms/Kilograms

ColorSilver

Product NameSteel Products

Steel TypeStainless Steel

Steel Product TypeOther, BRIGHT BAR

ShapeBar

SurfacePolished

Stainless Steel Bright Bar - Multiple Grades Available, Polished Surface Finish | Hot-Rolled Durability for Industrial Applications

Price: 220 INR/Kilograms

MOQ100 Kilograms/Kilograms

StandardANSI

Specific UseIndustrial

FinishPolished

TechniqueHot Rolled

GradeMultiple Grades Available

MaterialStainless Steel

Jicon Steel India

Mumbai

Trusted Seller

Trusted Seller2 Years

Steel Bright Bars - Alloy Steel Round, Hot Rolled Polished Finish | Custom Designed for Engineering and Automotive Applications

Price: 100 INR/Kilograms

MOQ100 Kilograms/Kilograms

Supply Ability100 Per Day

Delivery Time1 Week

Main Domestic MarketAll India

Stainless Steel Rods And Bars

Product DescriptionFor the miscellaneous requirements of our clients, we are involved in supplying, wholesaling and trading a wide array of Stainless Steel Rods And Bars to our clients. These are procured from reliable vendors, who make use of high grade of raw material and efficient machines. These are available in

Manganese Chromium Steel Bright Bars - Various Sizes & Dimensions | Exceptional Strength, Durability & Longevity

Product DescriptionWe are well known providers of Manganese Chromium Steel Bright Bars . These are applicable in automotive and industrial sectors. These bars are availabl

Hindustan Ferro Alloy Industries Pvt Ltd

Pune

Premium Seller

Premium Seller5 Years

Stainless Steel Bright Bar - Hot Rolled, Round Shape, Silver Color | Durable, Corrosion Resistant, Polished Surface Treatment for Versatile Use

MOQ50 Kilograms/Kilograms

TypeBar

Surface TreatmentBright

ShapeRound

TechnicsHot Rolled

UsageFor construction

ColorSilver

STAINLESS STEEL BRIGHT BAR

MaterialStainless Steel

ShapeRound

SurfaceBright

DiameterVariable

LengthVariable

ToleranceStandard

Stainless Steel Bright Bar By Kaviraj Metal Industries

Price: 200 INR/Kilograms

MOQ10 Kilograms/Kilograms

Supply Ability100000 Per Month

Delivery Time3 Days

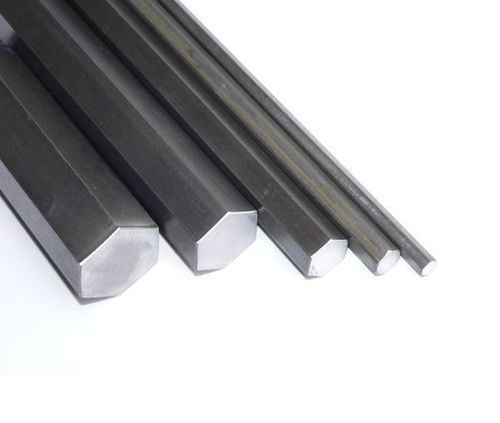

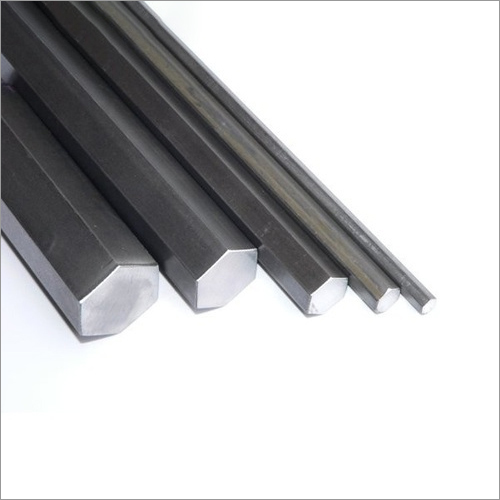

Stainless Steel Hexagonal Bars - 10-20 mm Diameter, 3-18 Meters Length | Ideal for Industrial Manufacturing and School Workshops

MOQ1000 Kilograms/Kilograms

Product NameStainless Steel Products

ShapeBar

ApplicationConstruction

ColorSilver, Grey

347 Stainless Steel Black T Bar - Application: Industrial

Price: 350 INR/Kilograms

MOQ50 Kilograms/Kilograms

ShapeRound

ColorSilver

TypeBar

ApplicationIndustrial

Steel TypeStainless

MaterialStainless Steel

Latest from Stainless Steel Bright Bars

Explore More Cities

Ready To Ship Stainless Steel Bright Bars

What are Stainless Steel Bright Bars?

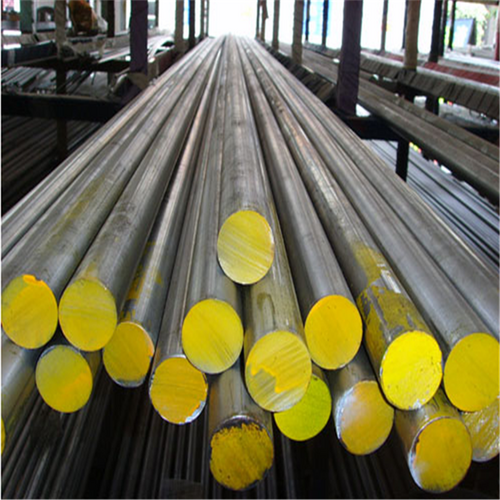

Stainless steel bright bars are precision-engineered metal rods or bars made from high-quality stainless steel alloys. What sets them apart is their smooth, lustrous surface finish, achieved through additional processing steps like peeling, grinding, or polishing. This distinguishes them from regular stainless steel bars, which have a rougher, untreated surface. These bright bars are known for their exceptional corrosion resistance, making them suitable for a wide range of applications in various industries. They offer high tensile strength and durability, ensuring they can withstand demanding environments. Additionally, stainless steel bright bars are relatively easy to machine and work with, which adds to their versatility.

Due to their polished finish and impeccable surface quality, they are often favored for applications where aesthetics and precision are critical. They find extensive use in industries such as automotive, aerospace, construction, manufacturing, and engineering. Common applications include shafts, fasteners, valves, precision components, and more. Stainless steel bright bars are available in a variety of grades, each with its unique properties and suitability for specific environments. The choice of grade depends on factors like corrosion resistance requirements, exposure to harsh chemicals or high temperatures, and other application-specific considerations. Overall, stainless steel bright bars are highly regarded for their combination of strength, corrosion resistance, and aesthetic appeal, making them a sought-after material in modern engineering and manufacturing.

Manufacturing of Stainless Steel Bright Bars

Stainless steel bright bars are manufactured through a series of carefully controlled processes to ensure precise dimensions, smooth surface finish, and high quality. The process starts with the selection of high-quality stainless steel alloys. These alloys are chosen for their corrosion resistance, mechanical properties, and suitability for the intended application. The chosen stainless steel is heated and passed through a series of rollers to form it into the desired shape. This initial shaping process helps create the basic form of the bright bar. The hot-rolled bars are then subjected to an annealing process. This involves heating the bars to a specific temperature and then slowly cooling them. Annealing helps improve the material's ductility and machinability. Peeling or Turning involves removing the outer layer of the bar using specialized machinery. This process smoothens the surface and removes any imperfections or irregularities, resulting in a brighter and more uniform finish. Polishing is the final step in the process. It involves using abrasive materials to achieve a smooth, reflective surface finish. This step is crucial in giving the bright bar its characteristic lustrous appearance. Throughout the entire manufacturing process, quality checks are performed to ensure that the bars meet industry standards for dimensions, surface finish, and material properties. The precise control and attention to detail in the manufacturing process contribute to the high quality and reliability of stainless steel bright bars.

Black Bars Vs. Bright Bars

Black bars and bright bars are two different forms of steel bars, each with distinct characteristics and applications:

Surface Finish:

Black bars have a rough, untreated surface. They are formed through hot rolling and do not undergo additional finishing processes. Bright bars undergo additional processes like peeling, grinding, or polishing to achieve a smooth, bright surface finish.

Appearance:

Black bars have a dark, non-reflective surface due to the presence of mill scale, which is an oxide layer formed during the hot rolling process. Bright bars have a smooth, lustrous surface that reflects light. This finish is achieved through mechanical or chemical processes.

Properties:

Black bars may have varying surface imperfections and irregularities, but they retain the mechanical properties of the steel. Bright bars have precise dimensions and a uniform surface, making them suitable for applications requiring tight tolerances and a refined finish.

Applications:

Black bars are commonly used in applications where surface finish and aesthetics are not critical. For example, in construction for structural elements like beams and columns. Bright Bars are preferred for applications where aesthetics, precision, and surface quality are crucial. Common uses include shafts, fasteners, valves, precision components, and applications in industries like automotive, aerospace, and manufacturing.

Types of Stainless Steel Bright Bars

Stainless steel bright bars come in various types, each designed to meet specific requirements for different applications. Here are some of the most common types of SS bright bars:

Austenitic Stainless Steel Bright Bars (304, 316):

These grades are characterized by their high chromium and nickel content, offering excellent corrosion resistance, high ductility, and good formability. They are widely used in industries like food processing, pharmaceuticals, and chemical processing.

Martensitic Stainless Steel Bright Bars (410, 420):

Martensitic grades have higher carbon content, making them hardenable by heat treatment. They are known for their high strength and good wear resistance and are commonly used in applications like cutlery, surgical instruments, and bearings.

Ferritic Stainless Steel Bright Bars (430):

Ferritic grades are characterized by their high chromium content and low carbon content. They offer good corrosion resistance in mildly corrosive environments and find applications in automotive trim, architectural components, and kitchen equipment.

Duplex Stainless Steel Bright Bars (2205, 2507):

Duplex grades combine the characteristics of both austenitic and ferritic stainless steel. They offer high strength and excellent corrosion resistance and are used in demanding environments like chemical processing, oil and gas, and marine applications.

Precipitation Hardening (PH) Stainless Steel Bright Bars (17-4PH):

PH grades can be heat treated to achieve high strength and excellent corrosion resistance. They find applications in aerospace components, nuclear reactors, and other high-stress environments.

Nitronic Stainless Steel Bright Bars (Nitronic 50, Nitronic 60):

Nitronic grades are known for their high strength, excellent corrosion resistance, and good wear resistance. They are used in applications like pumps, valves, and marine equipment.

These various types of stainless steel bright bars cater to a wide range of industries and applications, providing options that balance properties like corrosion resistance, strength, and machinability to suit specific needs. The choice of grade depends on factors like the environment, temperature, and mechanical requirements of the application.

Applications of Stainless Steel Bright Bars

Stainless steel bright bars find extensive applications across a diverse range of industries due to their exceptional properties and versatility.

1. Stainless steel bright bars are widely used in the automotive sector for various components such as shafts, axles, fasteners, and precision parts. Their corrosion resistance, high tensile strength, and durability make them essential for ensuring the longevity and performance of automotive systems.

2. In the aerospace industry, where safety and precision are paramount, stainless steel bright bars are used in critical components like landing gear, engine parts, and structural elements. Their ability to withstand extreme conditions, coupled with their high strength-to-weight ratio, makes them invaluable for aerospace applications.

3. Stainless steel bright bars are a cornerstone in manufacturing and engineering processes. They are utilized in the production of a wide array of machinery and equipment, including valves, gears, couplings, and hydraulic components.

Stainless steel bright bars are essential in the medical field for manufacturing surgical instruments, orthopedic implants, and dental equipment. The biocompatibility, corrosion resistance, and stabilizability of stainless steel are critical factors in ensuring the safety and effectiveness of medical devices.

4. Due to their excellent corrosion resistance in harsh saltwater environments, stainless steel bright bars are widely used in marine applications. They are found in components like propeller shafts, marine hardware, and offshore platform structures, contributing to the durability and reliability of marine equipment. These industries demand hygienic and corrosion-resistant materials.

5. Stainless steel bright bars are used in the construction of equipment like conveyors, mixers, and processing tanks. Their easy cleanability, resistance to corrosion from food acids, and inertness to chemical reactions make them indispensable in these applications.

Stainless steel bright bars are precision-engineered metal rods or bars made from high-quality stainless steel alloys. They stand out due to their smooth, lustrous surface finish, achieved through additional processing steps like peeling, grinding, or polishing. This sets them apart from regular stainless steel bars, which have a rougher, untreated surface. Known for their exceptional corrosion resistance, they find applications in various industries such as automotive, aerospace, construction, and healthcare. Their versatility, combined with properties like high tensile strength and durability, makes them indispensable in modern engineering and manufacturing.

Stainless Steel Bright Bars Price List

This Data was Last Updated on 2025-04-27

Stainless Steel Bright Bars Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Niko Steel And Engineering Llp Mumbai, India | 22 Years |

Steel Mart Mumbai, India | 19 Years |

British Super Alloys Pvt. Ltd. Ahmedabad, India | 13 Years |

Nascent Pipes & Tubes Mumbai, India | 11 Years |

Righton Impex Mumbai, India | 11 Years |

Devasya Engineers Ahmedabad, India | 10 Years |

Pragati Metal Corporation Mumbai, India | 7 Years |

Maharashtra Metal (india) Mumbai, India | 7 Years |

Harshvijay Exim Opc Private Limited Ahmedabad, India | 7 Years |

Dnr Alloys Mumbai, India | 7 Years |

Upcoming Tradeshows

FoodTech Kerala 2025

Thu, 22 May, 2025 - Sat, 24 May, 2025

Copper China 2025

Wed, 09 Jul, 2025 - Fri, 11 Jul, 2025

INDIAN ICE CREAM CONGRESS & EXPO 2025

Mon, 06 Oct, 2025 - Wed, 08 Oct, 2025

India Hospitality + F&B Pro Expo - Goa 2025

Fri, 09 May, 2025 - Sun, 11 May, 2025

Smart Home Expo 2025

Thu, 08 May, 2025 - Sat, 10 May, 2025

CPHI & PMEC China 2025

Tue, 24 Jun, 2025 - Thu, 26 Jun, 2025

International Crop Science Conference and Exhibition 2025

Tue, 10 Jun, 2025 - Wed, 11 Jun, 2025

WORLD OF HOSPITALITY EXPO 2025

Thu, 12 Jun, 2025 - Sat, 14 Jun, 2025

MachAuto 2025

Fri, 25 Jul, 2025 - Mon, 28 Jul, 2025

Asia Labex 2025

Wed, 11 Jun, 2025 - Fri, 13 Jun, 2025

Popular Categories