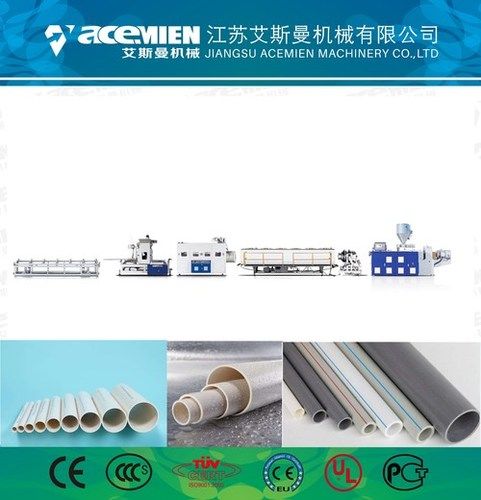

20 To 160mm Drain Pvc Pipe Extrusion Machine

Price: 20000 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

Product Specifications

| Type | 20-160MM |

| Material | PVC |

| Capacity | 250Kg/H Kg/hr |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Control System | PLC Control |

| Drive Type | Direct |

| Screw Diameter | 20-160MM Millimeter (mm) |

| Weight (kg) | 4000 Long Ton |

| Dimension (L*W*H) | 6X0.75X1.2 Meter (m) |

| Color | Customized |

| Warranty | 1 year |

| FOB Port | Shanghai |

| Payment Terms | Telegraphic Transfer (T/T) |

| Supply Ability | 20 Per Month |

| Delivery Time | 45 Days |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | WOODEN CASE PACKING AND PLASTIC FILM |

| Main Export Market(s) | Africa, Middle East, South America |

| Main Domestic Market | All India |

| Certifications | CE,ISO |

Product Overview

Key Features

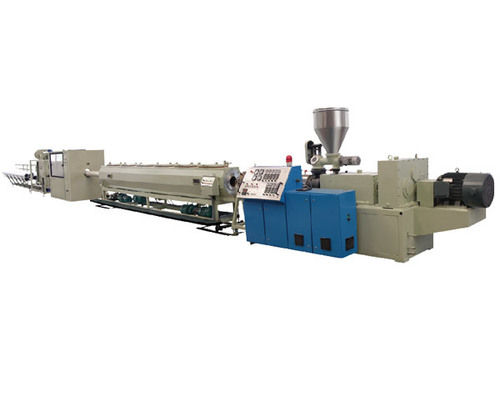

1. Extruder: adopting conical twin-screw extruder, unique designed screw, realizing the shorting plasticizing time good compounding and excellent plasticization.

2. Gearbox: adopting perfect quality gearbox, with a nice outline, stable running, low noise and long service time.

3. Extruding barrel temperature controlling system: adopting cast aluminum heaters with stainless steel covers, wind cooling system, ensuring good features of cooling and heating, precision temperature controlling.

4. Screw and barrel: screw-core installing with internal temperature controlling system, barrel equipped with vacuum degassing system, can get rid of the waste gas from the raw material which can guarantee super quality of the products.

5. Driving system: adopting A.C motor, using FUJI or ABB inverters which provide stable torque output and various speed.

6. Vacuum calibrating tank: with two vacuum chambers which can make sure the perfect roundness of the pipe, spraying water cooling, equipped with temperature controller, realizing automatic discharging the water, the main body of the tank make of stainless steel, long service time.

7. Haul-off machines: 2 laws, 3 claws, 4 claws, 6 claws, and 8 claws are provided to manufacture various pipes, haul-off speed governed by the FUJI or ABB inverter.

8. Cutting unit: saw cutting and planet saw cutting, with a dust collection system.

9. Staking unit: automatic overturning system, can freely fix the length of the pipe.

10. Controlling system: manual controlling cabinet or SIEMENS PLC touch screen control.

Using process:

Customer need to mix the raw material(PVC powder, Caco3, Ti2, and so on additives ) into Extruder, after plastify in extruder, material went into mould, the mould and vacuum tank form the material into pipes, after cooling tank, haul-off, and cutter, the pipes are produced well on the stacker.

Company Details

Xinda Precision Machinery Company has focused on the plastic machinery over 20 years with rich experience and strong technology support , our company is one of the key enterprises appointed by the China Ministry Light Industry. Our main products include carpet coating TPR TPE machine ; PVC pipe production line ; PVC WPC foam board production line machine ; PVC marble sheet extrusion line ; PE board sheet production line ; PVC imitation marble profile making machine ;PVC PC tile production line ; plastic floor making machine ; PE PP PPR pipe production line ; PVC ABS edge banding production line , PVC profile production line machine ; PVC lace gilding tableclothe production machine ; PVC lace cup mat coaster production machine ; PP PET strap production line ; TPR shoe welt making machine ; mixer, feeder etc.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

20

Establishment

1997

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

Seller Details

Zhangjiagang, Jiangsu

Vice General Manager

Mr John Yu

Address

Jinfen Town, Zhangjiagang, Jiangsu, 215600, China

pvc pipe extrusion line in Zhangjiagang

Report incorrect details