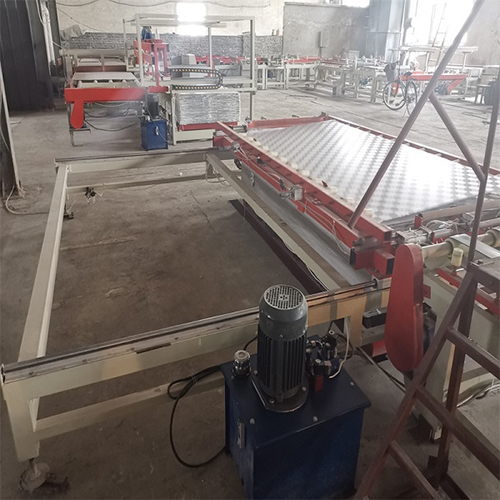

3.2m Wide Flat Sheet Machine For Truck Body Use

Price: 280000 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| FOB Port | XINGANG |

| Payment Terms | Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 4 set/month Per Month |

| Delivery Time | 90 days Days |

| Packaging Details | standard packing |

| Main Export Market(s) | Australia, South America, Middle East, Western Europe, Africa, Central America, Asia, Eastern Europe, North America |

| Main Domestic Market | All India |

| Certifications | ISO 9001 2008CE |

Product Overview

Key Features

3.2m FRP gel coat flat sheet production line( special for truck body)

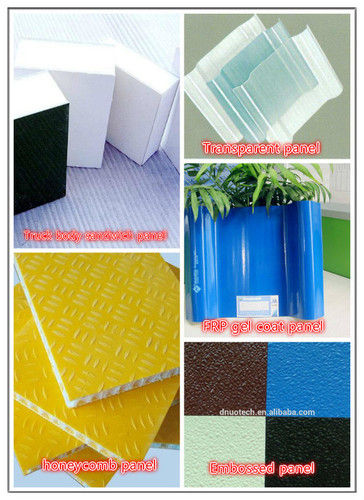

Function of equipment: this production line can produce 3.2m ultra-wide flat gel-coat sheet (special for Truck body)

Basic parameters:

Operation staff: 4-10A A A A speed of production: 2-5m/min

Sheet width: Maximum effective width is 3200mm

Thickness of sheet: 0.4-4.0mm

Main dimension of equipment: 75mA A 5mA A 3.5m

Power requirement: 280 kva

Power consumption: actual consumption is 150KW/h

This production line has EU certification, certified model FRP3200

Number of certificate: No.M7, 1302, 8307, 002

Machine characteristics:

1.Chain clip flattening techniques developed by Dnuo Technology Company, domestically first, this is the only equipment that could satisfy the requirement of high-levelness of truck body sheets.

2.Temperature-control raw material mixing techniques, real-time control on temperature and dosage of raw material, control the quality from the origin of production.

3.Able to conduct on-line spontaneous re-coiling of sheet by certain quantities, convenient for storage and transportation.

4.Width of product could be made on demand.

5.Whole line applies Ethernet total line communication, high speed, good stability. System is strong-expandable, able to connect host computer to conduct management to production, able to conduct remote service. Brands of electric control system could choose: DELTA, AB, Siemens to satisfy needs of various customers.

6.Impregnation platform multi-line independent temperature control, temperature control is precise, able to better adapt change of ambient temperature, quick impregnation, speed of production could be improved effectively;

7.Pulse-free metering system, metering is precise, wide range on flow rate adjustment, able to add powder fillers.

8.Easy operation based on PLC intellectual control system. Operate by computers, the production task and equipment operating data is faster and intuitional. Only short-term training can make operators complete production independently..

9.Multi-point temperature control chamber, unique arithmetic on temperature control, speed of heating is fast and temperature control is precise, improving quality of product and reduces energy consumption of equipment, degree of sheet curing is high.

10.Special cross cutting machine, good synchronization performance make accurate cutting.

11.Particular parts adopt special purpose wire, durable in use.

12.Size and layout of machine can be made according to customer requirements

After sale service:

Complete service system and professional team serve to customers with all efforts. Extended warranties can be offered.

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

150

Establishment

2000

Working Days

Monday To Friday

Payment Mode

Delivery Point (DP)

Certification

ISO 9001 2008,CE certification

Related Products

Explore Related Categories

Seller Details

Qinhuangdao, Hebei

Sales Department

Mr. Steven Han

Address

Add:Technology building,No.69,Longhai Road,Economic Development Zone, Qinhuangdao, Hebei, 066004, China

sheeting machine in Qinhuangdao

Report incorrect details