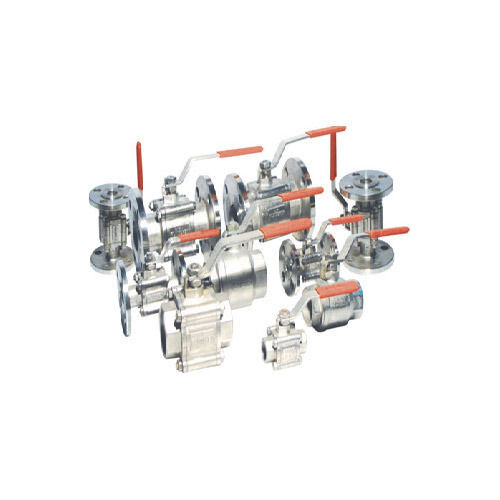

With vast industry experience and knowledge, we are instrumental in manufacturing, exporting and supplying of high quality 3 way ball valves. These valve are manufactured using quality metal alloy and contemporary technology. We also test our finished range on diverse parameters to ensure that the offered valves are in conformance with latest market standards. Our offered valves are provided with lower & higher pressure applications for chemical, oil and other industries. We are providing these 3 way ball valves in one Inlet and two outlets or Two Inlets and one outlet options according to the needs of our clientsFeatures: Excellent durability High Performance Maintenance free Trouble-free functionality Specifications: Mouting Interface: ISO 5211 MOC of the Body: WCB, CF8, CF8M, CF3, CF3M (Special on request) Trim: CF8, CF8M, CF3, CF3M (Special on request) Seat / Cavity Filler: PTFE, RPTFE (Special on request) Size: 1/2" to 8" Two Piece Flanged End VALVE A B C D E P.C.D. G HOLE H NOS SIZE #150 # 300 RB FB #150 #300 FB FB RB FB #150 # 300 #150 # 300 #150 # 300 15 108 140 9 12.7 89 95 74 76 117 117 60.5 66.7 16.0 16 4 4 20 118 152 14 19 98 117 76 91 117 150 69.9 82.6 16 19 4 4 25 127 165 20 25 108 124 91 97 150 150 79.3 88.9 16 19 4 4 32 140 178 25 32 117 133 97 130 150 250 88.9 98.5 16 19 4 4 40 165 190 32 38 127 156 130 133 250 250 98.6 114.3 16 22 4 4 50 178 216 38 50 152 165 133 160 250 585 121 127 19 19 4 8 65 190 241 50 65 178 191 160 173 585 585 140 149 19 22 4 8 80 203 283 63 80 191 210 167 196 585 737 152 168 19 22 4 8 100 229 305 80 100 229 254 205 245 737 925 191 200 19 22 8 8 150 267 403 100 152 279 318 245 280 925 1110 241 270 22 22 8 12 200 292 419 150 203 343 381 280 320 1110 1300 299 330 22 26 8 12 Three Piece Screwed / Socket Weld / Butt Weld Ends VALVESIZE A B C D E F G SCH.40 SCH.80 O. D. Wt. kgs RB FB RB FB RB FB I. D. I. D. 15 65 9.0 12.7 74 76 117 117 29 21.8 10 15.8 13.8 21.33 0.5 20 71 14.0 19.0 76 91 117 150 35 27.4 13 20.6 18.9 26.67 0.6 25 94 20.0 25.0 91 97 150 150 43 34.1 13 26.6 24.3 33.27 1.1 32 100 25.0 32.0 97 130 150 250 54 42.7 13 35.0 32.4 42.10 1.7 40 106 32.0 38.0 130 133 250 250 58 49.0 13 40.5 38.1 48.51 2.0 50 115 38.0 50.0 133 160 250 585 71 61.0 16 52.4 49.2 60.45 2.9 80 160 63.0 80.0 167 196 585 737 90.5 102 16 77.9 73.7 88.90 4.2 Material of Construction Description Material Body Carbon Steel / Stainless Steel Ends Carbon Steel / Stainless Steel Balls Stainless Steel Stem Stainless Steel Gland Stainless Steel Disc Spring Stainless Steel Lock Nut Stainless Steel Connector Bolt C.S /S.S Connector Nut C.S /S.S Seat PTFE / RPTFE Body Seal PTFE / RPTFE / Graphite Thrust Seal PTFE / RPTFE Gland Seal PTFE / RPTFE / Grafoil Standards Design and Testing Standard Description Product Standard Design Standard Valve BS 5351 Pressure Temp. Rating Shell ANSI B 16.34 Pressure Temp. Rating Seat BS 5351 /Manufacturers Shell Thickness Body BS 5351 / ANSI B 16.34 Face to Face Valve ANSI B 16.10 Flange Dimensions Ends ANSI B 16.5 Screwed Dimensions Ends ANSI B 1.20.1 / BS 21 / 5351 Socked Weld Dimensions Ends ANSI B 16.11 / BS 21 / 5351 Butt Weld Dimensions Ends ANSI B 16.25 / BS 21 / 5351 Testing Valves BS 6755 Part 1 / API 598 Fire Safe Testing Valves API 607 / BS 6755 Part II Non Destructive Testing Shell ANSI B 16.34 Break Away Torques in Kg-M SIZE CLASS 150 CLASS 300 CLASS 800 15 RP 0.2 0.3 0.4 20 RP 15 FB 0.25 0.4 0.6 25 RP 20 FB 0.3 0.5 0.7 32 RP 25 FB 1.0 1.4 1.6 40 RP 32 FB 1.5 2.3 2.9 50 RP 40 FB 1.9 2.5 3.1 65 RP 50 FB 2.7 3.5 4.5 80 RP 65 FB 4.8 8.0 . 100 RP 80 FB 8.0 13.0 . 150 RP 100 FB 12.0 19.0 . 200 RP 150 FB 27.0 41.0 . 200 FB 57.0 86.0 . Valves Co - efficient : Cv (USGPM) Valve Size 15 20 25 32 40 50 65 80 100 150 200 Full Bore 12.50 28.00 44.64 80.00 112.00 195.00 315.00 440.00 775.00 1745.00 3110.00 Reduced Bore 6.80 14.80 30.00 47.00 68.00 108.00 - - - - -