30kw, 50kw 100kw Rice Husk Gasifier

Price:

Get Latest Price

In Stock

Product Overview

Key Features

2. The preparation of biomass materialBefore utilization, the biomass material should be treated to control the size and humidity. For those irregular and higher humidity materials, the crushing and drying treatment is need.

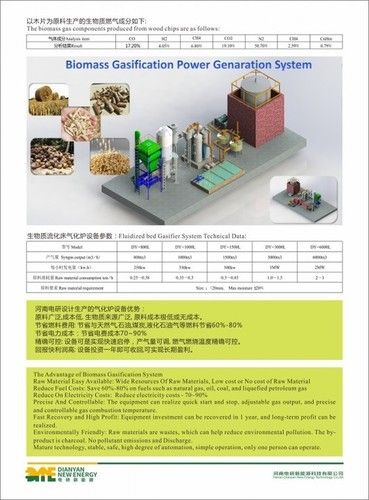

3. Biomass gasification and gas cleaning(taking an example for 1mw)

The biomass gasification adapts 1sets of fixed bed gasifier I 3.0M which can produce 3000 cubic syngas, which has the advantage of fast start and stop (start the gasifier within 10 minutes and stop it within 10 minutes), broad steady load quickly following the load and easy operation (only need 2~4 workers). The material consumption depends on material. Now the preliminary cleaning method is scrubber. The gas that contains impurity enters into scrubber. The impurity is taken away by washing water. The washing water is purified by water treatment equipment. The treated water recycles in scrubber. The tar and charbiomass dust separated from washing water are sent to biomass charbiomass production line as material. Because of the evaporation of washing water, some fresh water needs to be adding to scrubber. Advantage of dianyan biomass power plant:

1. The rate of return on investment is high. Taking 1MW as an example, the capital can be recovered around 2-3 years.

2. Wide range of raw materials, such as straw, rice husk, agricultural and forestry waste, nut shell, animal manure, etc

3. We are a high-tech enterprise with own production center and technical develop center. We have core technology and experienced expert R&D team. We have independent intellectual property rights, invention and practical patents. We have passed ISO three system certification, SGS international testing, CE certification, etc.

4. Perfect service, providing professional and free pre-sale technical solutions, and responsive after-sales service within 12 hours

5. The material of the equipment is durable, and the interior is made of high alumina refractory brick, which is resistant to high temperature of 1500 a and has a service life of 15-20 years. The gasification efficiency is higher than that of peers, which can reach 75-58%

6. There are several successful projects. For example, 400KW rice straw gasification plant in Thailand and Maymar,cashew nut shell power plant in Segnal ,nigeria,serbia etc.

7. The gasifier can work continuously for 24 hours a day and 8000 hours a year.

8. The equipment is easy to operate, saves labor cost, and has low maintenance cost once a month;

9. Our biomass gasification (power generation) production line is co production of carbon and gas. The gas produced can replace natural gas, coal and other fossil fuels for industrial heating and power generation. The raw materials are inexhaustible and more environmentally friendly. Compared with direct combustion of biomass, gasification gas is cleaner and can produce about 20% of biochar. After deep processing, carbon can be used for industrial heating and power generation Barbecue charcoal, organic fertilizer, etc., with high added value.

Company Details

Focusing on a customer-centric approach, HENAN YINGCHUANG MEDICAL TECHNOLOGY CO., LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Energy Conservation Products in bulk from HENAN YINGCHUANG MEDICAL TECHNOLOGY CO., LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

2015

Working Days

Monday To Sunday

Related Products

Seller Details

Zhengzhou, Henan

Wandayu

Address

No.43, 11Th Floor, Building 1, No.49, Jinshui East Road, Henan Free Trade Zone, Zhengzhou, Henan, 450001, China

biomass gasifier in Zhengzhou

Report incorrect details