Forklifts

(2207 products)Strong Diesel Forklift

MOQ10 Unit/Units

UsageIndustrial

SizeCustomized

ConditionNew

Power SourceHydraulic

FeatureHigh Quality

AttributesStrong

Yellow-Black Heavy Duty Scissor Lift Table

Price: 195000 INR/Piece

MOQ1 Piece/Pieces

ConditionNew

ColorYellow-Black

UsageIndustrial

Product TypeHeavy Duty Scissor Lift Table

TypeScissor Lifts

Loading Capacity3 Tonne

Pulling Lifting Machine - Application: Storage Yard

MOQ1 Piece/Pieces

UsageFor Lifting

Product TypePulling Lifting Machine

ConditionNew

TypeOther, Lifting Machine

ApplicationConstruction, Storage Yard, Factory

Lifting Capacity2-5 Tonne

Orange Jk Mini 1000 Crane With 1 Bucket Wire Rope Guide Type Remote Controlled - Color: Blue

Price: 410000 INR/Piece

MOQ1 Piece/Pieces

ConditionNew

Weight1200 Kilograms (kg)

ColorBlue

UsageIndustrial / Construction

Product TypeOrange JK Mini 1000 Crane Wire Rope Guide Type Remote Controlled

Power SourceAC Motor

Manual Aerial Work Platform - Color: Yellow

Price: 400000 INR/Unit

MOQ1 Unit/Units

Product TypeManual Aerial Work Platform

ColorYellow

Loading Capacity100-200 Kilograms (kg)

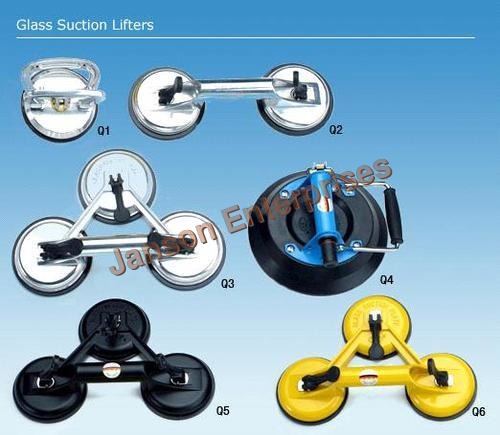

Glass Lifter With Two Cups Application: 1.2 Kgs

Price: 1920 INR/Piece

MOQ100 Piece/Pieces

ColorSilver

MaterialSteel

Screen Netting MaterialStainless Steel

Application1.2 kgs

Paper Roll Clamp Forklift - Mild Steel, 4 Ton Load Capacity, 12 Feet Lifting Height, Yellow Paint Coated Finish | 1 Year Warranty, New Industrial Usage

Price: 150000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

Product TypePaper Roll Clamp Forklift

ConditionNew

ColorYellow

Loading Capacity4 Tonne

Warranty1 Year

Semi Electric Stacker - 2 Ton, 3 Mtr Height | Durable Red & Black Finish, New Condition, Industrial Use, 1 Year Warranty

Price: 138500.0 INR/Piece

MOQ1 Piece/Pieces

Product TypeSemi Electric Stacker 2ton 3 Mtr

UsageIndustrial

SizeAll size

ConditionNew

ColorRed & Black

Warranty1 Year

Adjustable Hoist Stirrup

Price Trend: 190000.00 - 250000.00 INR/Piece

MOQ1 Piece/Pieces

FOB PortMundra, Gujarat, India

Supply AbilityAny Per Month

Delivery Time1 Days

Hydraulic Glass Passenger Lift, Maximum Rise: 5-10m

Product DescriptionHydraulic Glass Passenger Lift

Suspended Rope Platform (Srp) Europa Application: Construction

MOQ1 Set/Sets

ConditionNew

ApplicationConstruction

Tig Marketing And Leasing Company

Navi Mumbai

Kapmix Suspended Cradle Platform Power Source: Ac Motor

Price: 210000 INR/Unit

MOQ1 Unit/Units

SizeDifferent Sizes Available

UsageIndustrial

ConditionNew

Turning RadiusNormal

Power SourceAC Motor

WarrantyYes

M/s Kapmix Machinery Private Limited

Ghaziabad

Weather Resistance Easy To Install Monkey Lift (Maximum Lifting Capacity 300 Kg) Application: Construction

Price: 115000 INR/Unit

MOQ1 Unit/Units

UsageMaterial Handling use

ConditionNew

ColorRed, Black

ApplicationConstruction

Loading Capacity300 Kg Kilograms (kg)

Pulling Lifting Machine - Color: Silver

Price: 22000 INR/Unit

MOQ1 Unit/Units, Unit/Units, Unit/Units

UsagePULLING

ConditionNew

Product TypePulling Lifting Machine

Length10 Meter (m)

ColorSilver

Size10MTR

Monkey Lift Machine Application: Construction

Price: 85000 INR/Unit

MOQ1 Unit/Units

Usageindustrial

ColorYellow

ConditionNew

Product TypeMonkey Lift Machine

ApplicationConstruction

Warranty1 Year

Heavy Duty Forklift - Application: Warehouse

Price: 1000000 INR/Unit

MOQ1 Unit/Units

SurfacePainted

SizeStandard

Product TypeForklift

ConditionNew

UsageMaterial Handling

MaterialMild Steel

Triguna Forklift Service

New Delhi

Electric Forklift - Color: As Per Requirement

Price: 1395000 INR/Unit

MOQ1 Unit/Units

BrakeYes

Product TypeElectric Forklift

ConditionNew

ColorAs per requirement

UsageIndustrial

TypeFour-Wheel Forklifts

Battery Operated Pallet Truck - Color: Yellow & Black

Price: 500000 INR/Piece

MOQ1 Unit/Units

ConditionNew

MaterialMS

Product TypeBattery Operated Pallet Truck

UsageWarehouse, Industrial, Logistics

SizeStandard

ColorYellow & Black

Balvika Industrial Equipments Pvt. Ltd.

Kolkata

Premium Seller

Premium Seller1 Years

High Strength Steel Construction Forklift Forks

ConditionNew

UsageMaterial Handling

Product TypeForklift Forks

ColorYellow and Black

TypeOther, Forklift Forks

ApplicationFactory, Warehouse

Sk Engineering & Equipments

Coimbatore

Trusted Seller

Trusted Seller6 Years

Stainless Steel Scarlet Multi Products Furniture Mover Lifter Tool Application: Construction

Price: 550 INR/Piece

MOQ150 Piece/Pieces

ConditionNew

Product TypeStainless Steel Scarlet Multi Products Furniture Mover Lifter Tool

ColorRed and Black

Size32L x 10.3W x 7.6H Centimeters

ApplicationConstruction, Workshop

Scarlet Multi Products Private Limited

Rajkot

Premium Seller

Premium Seller2 Years

75Mtr Orange Suspended Platform Height: 1.15M - 1.75M Meter (M)

Price: 2,24,000 INR/Unit

MOQ1 Unit/Units

ConditionNew

Size9.1 mm Wire Rope Size

Product Type75mtr Orange Suspended Platform

Height1.15m - 1.75m Meter (m)

UsageIndustrial

WarrantyYes

Ashley Industries

Mumbai

Trusted Seller

Trusted Seller2 Years

Wire Rope Suspended Platforms - Color: White

Price: 185000 INR/Piece

MOQ1 Quintal

ColorWhite

Product TypeWire Rope Suspended Platforms

UsageIndustrial

Forklift - Heavy-Duty Steel Frame, Ideal for Efficient Materials Handling

Product DescriptionWe are manufacturing, exporting and supplying huge range of Forklifts in Chennai, Tamil Nadu, India. Our given range are widely appreciated by our customer which are located all round the nation. Ideal for materials handling purpose. Apart from this, these can be availed from us at reasonable prices

Yagyapriyaa Construction Equipment India Pvt. Ltd.

Chennai

R16S Linde Heat Resistance Pu Wheel Reach Trucks (Lifting Capacity 1.6 Ton) Application: Construction

Price: 8000000 INR/Unit

MOQ1 Unit/Units

ConditionNew

ColorOrange,Black, Red, Blue

Product TypeReach Trucks

UsageMaterial Handling use

TypeReach Trucks, Other

ApplicationConstruction, Workshop, Factory

Om Mhe Tech Private Limited

Thane

Trusted Seller

Trusted Seller3 Years

Aerial Work Platform

Price: 200000 INR/Unit

MOQ1 Unit/Units

ColorWhite

Product TypeAerial Work Platform

ConditionNew

Dual Mast Aerial Work Platform - Application: Construction

Price: 450000 INR/Unit

MOQ1 Unit/Units

SizeDifferent Size

ConditionNew

UsageIndustrial

ColorSilver

ApplicationConstruction

Loading Capacity200-250 kg Kilograms (kg)

Hydraulic Lifting Trolley Table

Price: 350000 INR/Piece

MOQ1 , Piece/Pieces

Supply Ability10-15 Per Month

Delivery Time30 Days

High Performance Electric Forklift

Price: 1000000 INR/Piece

MOQ1 Piece/Pieces

Product DescriptionTrucks are suitable for a variety of indoor and outdoor operations, including loading and unloading goods, line feeding, stacking, order picking and horizontal transport. With a battery choice between 48 and 80 volts, and load capacities

Latest From Forklifts

Compact Mariotti Forklifts

By:

Mhe Next Engineering Pvt. Ltd.

Electric Forklifts

By:

Balvika Industrial Equipments Pvt. Ltd.

Ready To Ship Forklifts

What is a forklift?

Forklifts are a type of industrial truck that is driven by an internal combustion engine. Short-distance lifting and transporting of a wide variety of items is their primary function. Forklifts are characterized by a compact truck chassis that houses a forward-facing mast assembly that raises and lowers the cargo.

Working Mechanism of Forklift

1. Counterweight

A cast-iron weight, the Counterweight, is fastened to the back of the forklift. The counterweight's job is to equalize the weight of the raised object. The counterweight of an electric forklift is attached to the lead-acid battery.

2. Carriage

The forklift is mounted on a carriage, which provides support. As the Carriage is mounted on mast rails, it may be raised and lowered with ease.

3. Truck Frame

The frame of the truck is the primary structural element. Wheels, a counterweight, and a mast, all essential forklift parts, are fastened to the truck frame.

4. Mast

The Mast is an upright structure that hoists and lowers cargo. Mast is made up of horizontally-controlling Interlocking Rails.

5. Power Source

A gasoline-powered internal combustion engine drives the forklift. The engine accepts liquid petroleum gas (LPG), compressed natural gas (CNG), diesel, and natural gas as fuel.

Where is a forklift used?

1) Warehouses- When working in a warehouse, forklifts are an indispensable tool. To load and unload vehicles and deliver products is their primary function. Warehouses may make use of several distinct kind of forklifts. The sizes and functions of each tool are unique.

2) Building constructions- Industrial forklifts are also handy on building projects. Forklifts are essential for construction workers because they allow them to transfer large goods over long distances and across uneven ground with ease. Forklifts are used as both vehicles and lifting equipment on construction sites.

3) Dockyards- Forklifts were crucial throughout both World Wars for unloading and stacking barges and ships. Forklifts are now often employed to carry and transfer heavy goods from their origins in delivery trucks to their destinations on ships or in dockside storage areas. After receiving their cargo, wood, and steel are transported using this method.

4) Recycling facilities- Forklifts have several uses outside of dockyards, including recycling activities. It is where recycling bins and vehicles discharge their goods before taking them to be sorted. With its ability to load and unload tractor-trailers, elevators, railroad carriages, and straight trucks, forklifts are favored in various settings.

How to operate a forklift?

1. Pre-Operational Checks Being Performed

Each shift must begin with a thorough pre-operational examination performed by the operator. Although forklifts are tough devices, they do eventually break down due to normal use.

-Controls

-Fuel, engine oil, and radiator water levels

-Battery plug connections

-Battery is fully charged

-Wheels and tires

-Electrolyte levels and cells

-Chain anchor pins

-No damp spots beneath forklift (could indicate a leak)

-Hydraulic hose reels

2. Rotation of Pallets

Before entering a pallet, operators should check that the prongs are level and in the right place. Having level forks will make sure your load is distributed evenly (if uneven, the forklift can tip over). Safely transporting pallet loads requires knowledge of pallet sizes and load center calculations. Do not try to move the load once it has been placed on the forks. Do not utilize a forklift-parked pallet as a work surface.

3. Loading

There is a suggested load limit for each type of forklift listed on the information plate. Overloading a forklift might result in significant damage, therefore please don't treat these weight restrictions as suggestions.

Knowing one's capabilities, however, is not sufficient. Forklift tip-overs may be avoided with proper weight distribution. To operate a forklift safely and efficiently, one must learn how to properly organize and balance loads.

4. Lifting the Burden

Keep the fork at all times until the vehicle has come to a complete stop and the brake has been applied. Lift the object straight up, and then tilt it back slightly. Forklifts lose part of their stability after a load is lifted, therefore tilting the load restores that stability.

Don't raise anything that would cause the load to go over the truck's backrest. Having the ability for some or all of the weight to transfer back toward the driver is exceedingly dangerous. Whenever you're working outside, it's important to keep a safe distance from power lines, and you should always make sure there's enough overhead clearance before lifting a load.

5. Traveling

No of the weight on the forks, they should be kept as close to the ground and leaned back as feasible at all times.

Always brake and honk the horn before entering turns. Keep an eye on how the cargo and truck's back end are swaying. Stay away from unexpected stops if all possible. Slowly reversing is the safest option if you can't see forward because of the weight.

6. Steering

Because lifts are so much more top-heavy, and much more so when the prongs are at the top of the mast, steering a forklift is very different from maneuvering a car. Since an S forklift is driven by its back wheels, accelerating and braking suddenly is quite challenging.

7. Entering Elevators

If you are not expecting to ride the elevator, you should not enter it. Before entering an elevator, check to see that the total weight of the load, the driver, and the forklift does not exceed the elevator's maximum weight limit.

What are the industrial uses of forklifts?

As mentioned above, Forklifts are used in different industrial works. They are used for transporting, raising, lowering, and removing heavy loads or several light loads on pallets or in boxes, crates, or other containers.

10 Common Forklift Types & Classifications

1. Side loader

Side load forklifts are advantageous in that they can load and unload from racks without having to turn the vehicle around. Uses- Transporting bulky, lengthy objects like pipes and lumber.

2. Telehandler

A common telehandler can raise objects weighing up to 5,500 pounds to a height of 19 feet, making it ideal for accessing high, hard-to-reach places and working with confined areas and unusual angles. Uses- Carrying weights to higher altitudes.

3. Warehouse Forklift

Most effective for lifting and moving objects over relatively short distances.

4. Counterbalance forklift

It's useful for when you need to do some circling.

5. Heavy-duty forklift

Uses- To move bulky objects for use in manufacturing

6. Rough Terrain Forklift

These trucks' pneumatic tires are larger and threaded for increased balance and stability, making them suitable for transporting products across uneven terrain.

7. Pallet Jacks

Pallet jacks can raise light objects in confined locations since they have a compact footprint despite their powerful motors.

8. Walkie Stackers

If you need a taller pallet jack but don't have a lot of power, mobility, or speed to spare, consider one of these. Elevating pallets beyond the reach of a pallet jack.

9. Order Picker

The walkie-stacker family includes a specialized vehicle called an order picker that is used to retrieve and transport goods from storage. Applications for item picking and inventory management in warehouses.

10. Reach Fork Truck

The warehouse vehicle known as a reach forklift is mostly employed inside. The essential feature is that its prongs may extend outside the compartment, allowing it to access racks in a warehouse in a way that other forklifts cannot.

Classifications

Class I- Electric Motor Forklifts

Fuel type: Electric

Use: Indoor environments with poor air quality

Class II- Electric Motor Narrow Aisle Truck

Fuel Type: Battery

Use: Transporting goods across confined areas

Class III- Electric Motor Hand Truck

Fuel Type: Battery

Use: Rapid unloading of cargo vehicles over brief distances

Class IV- Internal Combustion Engine with Cushion Tires

Fuel Type: Gas or Diesel

Use: Low clearance situations

Class V- Internal Combustion Engine Trucks with Pneumatic Tires

Fuel Type: Diesel and Gas

Use: Indoor and Outdoor with rough surfaces

Class VI- Electric and Internal Combustion Engine Tractors

Fuel Type: Battery, gas, or diesel

Use: Hauling or Towing loads

Class VII- Rough Terrain Forklift Truck

Fuel Type: Gas or Diesel

Use: Construction sites, uneven ground, high-elevation lifting

FAQs: Forklift

Question: How to choose the right forklift for your business?

Answer: Here are some guides:

Figure out how much you can do. What's the required lifting capacity?

Assess the steadiness of the construction site. Can the forklift drive on this surface?

Find out how high the ceiling is. Is your forklift able to fit through doorways?

Do the math and choose the right fuel. Is electricity or gas required?

Try to get a feel for the area. What kind of texture does the surface have, if any?

Question: How to unload a truck with a forklift?

Answer: To unload a truck with a forklift, do the following:

The trailer's curtain must be opened.

Check that the tynes are perpendicular and level with the weight.

Tynes should be aligned with the corresponding pockets on the pallets.

See to it that the forklift is set up correctly.

Turn the trailer's cargo around.

Question: How to change hydraulic oil in a forklift?

Answer: Do the following to change hydraulic oil in a forklift

-Always Park your forklift on a flat surface.

-Make sure the tynes are down to the ground

-Put on the brakes and turn the key off.

-Lift the hood to access the vehicle's hydraulic oil storage tank

-If you haven't already, consult the owner's handbook or the company that made your forklift to make sure the reservoir holds enough hydraulic oil.

-Under the drain plug at the base of the oil reservoir, place a container with sufficient volume to hold the whole oil supply.

-First, take off the drain plug and empty the old hydraulic oil.

Question: How to safely fill a forklift LPG cylinder?

Answer: If you wish to safely fill a forklift LPG cylinder, do the following:

-Put the forklift to rest, and turn off the engine.

-Check to see that no workers are still riding the forklift.

-Verify that the worker has refilled

-To disconnect the female ACME from the service valve, turn off the service valve.

Question: How to safely move a disabled forklift?

Answer: Do the following steps to safely move a disabled forklift:

-Evaluate the potential dangers of the current towing condition.

-Ensure the fasteners holding the counterweight in place are secure.

-Impede a stalled truck's wheels.

-Be sure the tow chain is locked in place.

-Take your foot off the brake

-Take away the obstructing wheels

Manufacturers & Suppliers of Forklifts

Company Name | Member Since |

|---|---|

Yash Pal & Co. Kolkata, India | 19 Years |

Servo Tech India Alwar, India | 19 Years |

Amratlal Chhaganlal Mumbai, India | 17 Years |

Balaji Construction Machinery Rajkot, India | 14 Years |

Tig Marketing And Leasing Company Navi Mumbai, India | 14 Years |

The Janson Enterprises New Delhi, India | 12 Years |

K Y Industries Ahmedabad, India | 11 Years |

Sfs Equipments Private Limited Chennai, India | 8 Years |

E.S. Industries Coimbatore, India | 6 Years |

Sk Engineering & Equipments Coimbatore, India | 6 Years |

Popular Products