Wire Mesh

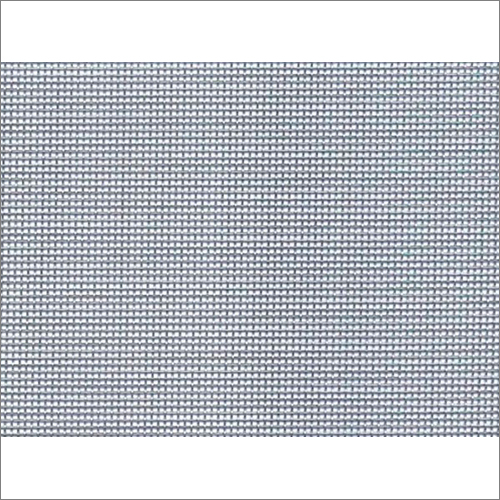

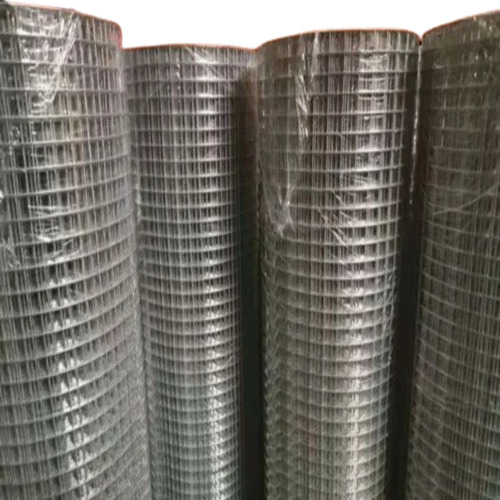

(6467 products)Gi Wire Mesh - Galvanized Iron Wire Mesh, Rectangle Hole Design, Silver Color, Corrosion Resistant Customizable Solutions

Price: 66 INR/Kilograms

MOQ100 Kilograms/Kilograms

Surface TreatmentGalvanized

Hole ShapeRectangle Hole

Product TypeWire Mesh

Mesh TypeIron Wire Mesh

MaterialIron

ColorSilver

Super Welded Mesh

Kolkata

3 Years

Super Premium

Super PremiumFilter Bag Cage Wire - Color: Silver

Price: 35 INR/Kilograms

MOQ1 Kilograms/Kilograms

Surface TreatmentGalvanized

Hole ShapeRound Hole Triangle Hole

MaterialStainless Steel

AlloyWith Alloy

ColorSilver

Precise Alloys Pvt. Ltd.

Mumbai

Super Bonanza

Super Bonanza18 Years

Sliver Mist Eliminator Demister

Price Trend: 5000.00 - 25000.00 INR/Piece

MOQ5 Piece/Pieces

Hole ShapeSquare Hole

Product TypeWire Mesh

Mesh TypeIron Wire Mesh

MaterialSteel

ColorSliver

Indo German Wire Screen Co.

Mumbai

11 Years

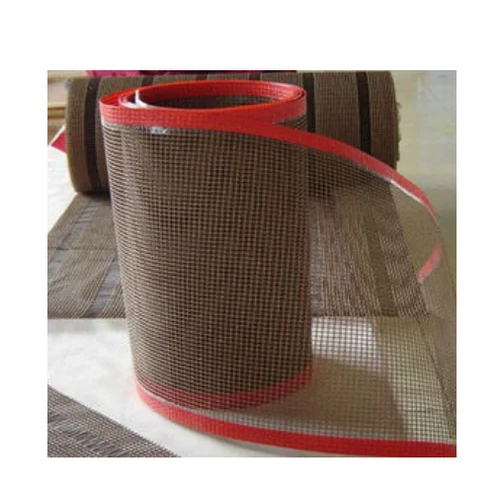

Fibre Glass Mesh - High-Strength Alkali Resistant | Flexible, Waterproof, Thermal Resistant, Mildew Resistant, Soft, Durable

Product DescriptionWith the active support of our team of experts, we are Exporter, Manufacturer & Supplier of Fibre Glass Mesh in Noida, Uttar Pradesh, India. In order to manufacture this mesh as per the international quality standards, our dexterous professionals make use of superior-quality fibers and state-of-art

Virendera Textiles

Noida

17 Years

Fine Wire Mesh Hole Shape: Square Hole

Price Trend: 200.00 - 2000.00 INR/Square Foot

MOQ4 Square Foot/Square Foots

Surface TreatmentPolished

Hole ShapeSquare Hole

Product TypeWire Mesh

MaterialOther

Superfit Engineering Private Limited

Mumbai

4 Years

Super Premium

Super PremiumD & H Secheron Electrodes Private Limited

Indore

5 Years

Stainless Steel & High Nickel Alloy Spring Wire

Price: 300 INR/Piece

MOQ10000 Piece/Pieces

Product DescriptionStainless Steel & High Nickel Alloy Spring Wire

Labh Projects Pvt. Ltd.

Ahmedabad

5 Years

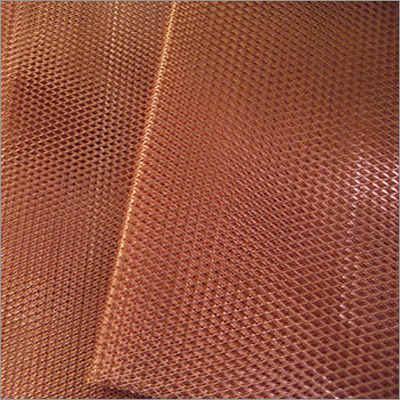

Twill Cutting-Edge Copper Wire Mesh

Price: 60 INR/Square Foot

MOQ5000 Square Foot/Square Foots

Supply Ability20000 Per Week

Delivery Time4 Week

International Wirenetting Industries

Palghar

21 Years

Stainless Steel Wire Mesh - Color: Silver

Price: 90 INR/Square Foot

MOQ100 Square Foot/Square Foots

Surface TreatmentOther, Polished

Mesh StyleChain Link Mesh

MaterialStainless Steel

Wire Diameter10 Millimeter (mm)

ColorSilver

Banaraswala Wire Mesh Private Limited

Hyderabad

1 Years

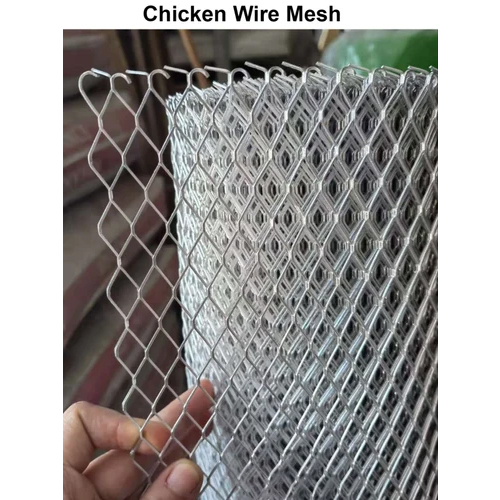

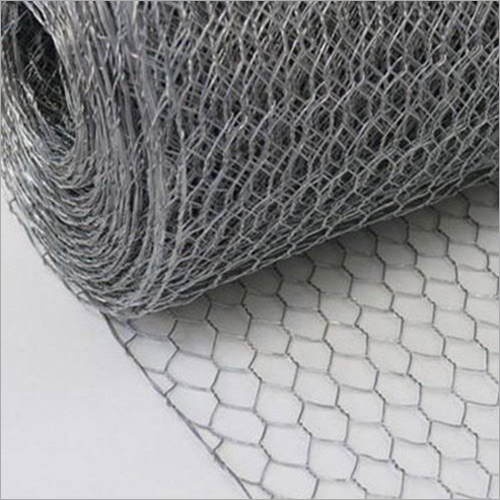

Chicken Wire Mesh - Color: Silver

Price: 4000 INR/Square Foot

MOQ100 Square Foot/Square Foots

Length10 Meter (m)

Surface TreatmentOther, Hot Rolled

Mesh StylePlain Mesh

MaterialOther, Galvanised Iron

Dimensions22 Millimeter (mm)

Wire Diameter0.55 mm Millimeter (mm)

Mesco Weldmesh Industries

Gandhinagar

1 Years

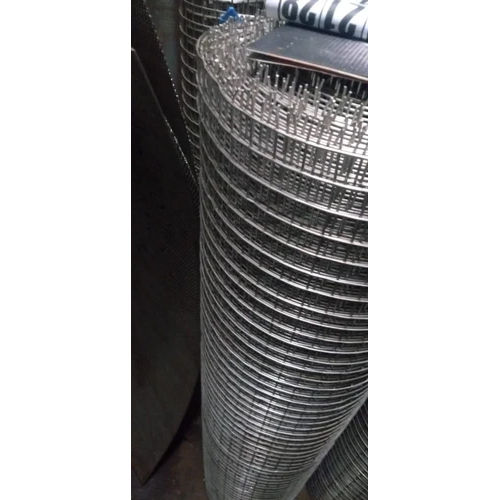

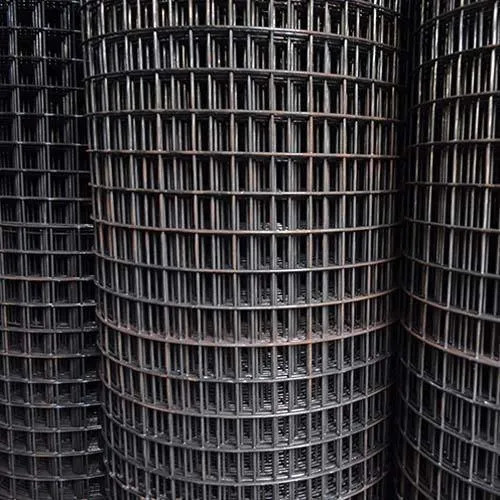

GI Welded Wire Mesh

Price: 50 INR/Kilograms

MOQ1000 Kilograms/Kilograms,

Payment TermsTelegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

Supply Ability10000 Per Month

Delivery Time3 Days

Kiran Wirenetting Stores

Kolkata

11 Years

Steel Wire Mesh - High-Strength Steel, Various Sizes Available | Corrosion Resistant, Versatile Applications

Price Trend: 40.00 - 400.00 INR/Square Foot

MOQ100 Square Foot/Square Foots

Supply Ability500 Per Day

Delivery Time1-7 Days

Gaylord Enterprise

Ahmedabad

11 Years

Signature Welding Blanket

Payment TermsDelivery Point (DP), Days after Acceptance (DA), Cheque

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Darshan Safety Zone

Ahmedabad

6 Years

Silver Industrial Demister Pad

Price: 15000 INR/Piece

MOQ100 Piece/Pieces

Product TypeIndustrial Demister Pad

UsageIndustrial

Colorsilver

ConditionNew

MaterialAluminium

ShapeRound

United Filters Industries Pvt Ltd.

Pune

11 Years

Silver Stainless Steel Welded Mesh By Artha Alloys

Price: 125 INR/Kilograms

MOQ10 Kilograms/Kilograms

Hole ShapeSquare Hole

Product TypeWire Mesh

Mesh TypeSteel Wire Mesh

Mesh StyleWelded Mesh

MaterialStainless Steel

ColorSilver

Artha Alloys

Mumbai

Super Bonanza

Super Bonanza3 Years

Industrial Aluminum Mesh

MOQ100 Square Foot/Square Foots

Surface TreatmentMill Finish

Product TypeWire Mesh

Mesh TypeAluminum Wire

MaterialAluminum

AlloyYes

Chirag Impex

Mumbai

2 Years

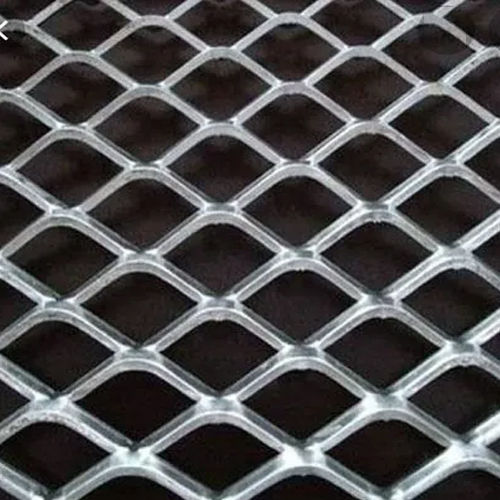

Aluminium Expanded Mesh - Lightweight Aluminum Material, Durable and Versatile Application

Price Trend: 90.00 - 100.00 INR/Kilograms

MOQ50 , Kilograms/Kilograms

Product DescriptionAluminium Expanded Mesh

Ss Wire Mesh Roll Application: Ceiling

Price Trend: 100.00 - 500.00 INR/Square Foot

MOQ50 Square Foot/Square Foots

Product TypeWire Mesh

Mesh TypeSteel Wire Mesh

MaterialStainless Steel

ApplicationCeiling

ColorSilver

S S Perforators

Khairthal

7 Years

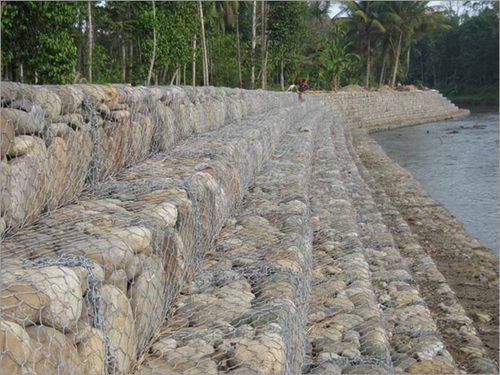

Flood Protection Gabion Box - Application: Solar Industry

MOQ100 Meter/Meters

Hole ShapeRectangle Hole

Surface TreatmentWelding

Product TypeWire Mesh

Mesh TypeSteel Wire Mesh

MaterialSteel

ApplicationFood Industry, Solar Industry

Ocean Non Wovens Pvt Ltd

Jhajjar

12 Years

Mild Steel Binding Wire - High Strength, Versatile Specifications | Longer Service Life, Economical Price, Reliable Performance

Payment TermsDelivery Point (DP), Days after Acceptance (DA), Cheque

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Shubh M L Shah Sons Steel Private Limited

Navi Mumbai

3 Years

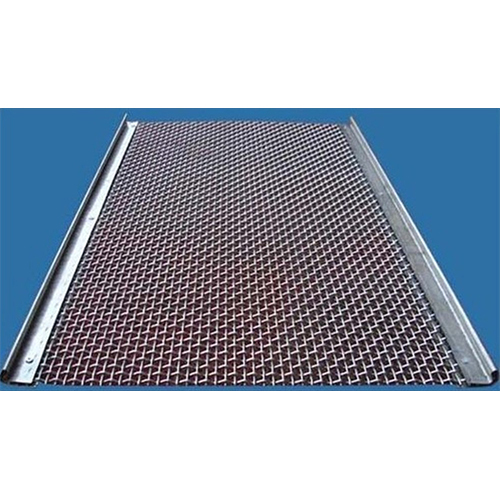

High Carbon Steel Mining Screen - Aperture: 1 Mm To 100 Mm

Price: 3000 INR/Kilograms

MOQ50 Kilograms/Kilograms

Hole ShapeSquare Hole

Aperture1 mm to 100 mm

Length15 Foot (ft)

Product TypeWire Mesh

Mesh TypeCarbon Iron Wire

Mesh StyleWoven Mesh

Hmb Engineering

Ghaziabad

17 Years

Expanded Metal Mesh - Aluminum Wire Mesh , Lightweight Silver Color with Powder Coating and Versatile Hole Shape Options

Price: 80 INR/Square Foot

MOQ150 Square Foot/Square Foots

Surface TreatmentPowder Coating

Hole ShapeRound Hole Triangle Hole

Product TypeWire Mesh

Mesh TypeAluminum Wire Mesh

Mesh StyleExpanded Mesh

MaterialAluminum

Auto Tech Industry

Gurugram

3 Years

Poultry Chicken Safety Wire

Price: 750 INR/Roll

MOQ2 Roll/Rolls

Surface TreatmentCoated

Hole ShapeOther , Hexagonal

ColorSilver

Product TypeWire Mesh

MaterialStainless Steel

ApplicationOther

Punrasar Engineering Pvt. Ltd.

Kolkata

4 Years

Fencing Razor Barbed Wire

Price: 680 INR/Roll

MOQ100 , Roll/Rolls

Surface TreatmentPolished

Product TypeWire Mesh

Mesh TypeSteel Wire Mesh

B. C. Nandy & Co.

Kolkata

4 Years

Fiberglass Mesh - White Wire Mesh, Powder Coated Finish, Square Hole Design

Price: 750 INR/Roll

MOQ50 Roll/Rolls

Surface TreatmentPowder Coating

ColorWhite

Hole ShapeSquare Hole

Product TypeWire Mesh

AlloyNo

Hira Wire Netting Industries

Raipur

3 Years

Welded Wire Mesh - Steel Material, Polished Finish | Versatile, Durable, Easy to Install, Corrosion-Resistant

Price: 165 INR/Square Foot

MOQ100 Square Foot/Square Foots

Surface TreatmentPolished

Product TypeWire Mesh

MaterialSteel

Jay Mogal Weldmesh Industries

Surat

3 Years

316 Stainless Steel Wire - Color: Silver

Price: 240 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorSilver

Surface TreatmentPolished

Product TypeWire Mesh

Mesh TypeSteel Wire Mesh

MaterialStainless Steel

AlloyNon Alloy

Jai Jirawal Metal & Alloys

Mumbai

10 Years

Gi Gabion Box - Material: Iron

Price: 75 INR/Cubic Meter

MOQ1000 Kilograms/Kilograms

Wire Gauge2.70mm/3.70mm, 2.50mm/3.50mm, and 3.0mm, 4.0mm

Hole ShapeOther

Surface TreatmentGalvanized

Product TypeWire Mesh

Mesh TypeGalvanized Iron Wire

Mesh StyleWoven Mesh

Secure Matrix Constro Engineering Solutions

Pune

4 Years

Latest From Wire Mesh

Ready To Ship Wire Mesh

A:- Introductions of Wire Mesh

Wire mesh is made by weaving, interlacing, or welding together wires of varying diameters to form a grid of squares and rectangles with openings of uniform size.

Wire mesh is made by weaving wire on industrial looms to create a fabric with square or rectangular openings, also called a wire fabric, wire cloth, or hardware mesh.

Wire mesh comes in an infinite variety of shapes, sizes, and configurations created from a wide range of highly durable and resilient materials, and its primary purpose is to partition, screen, structure, and protect a wide range of uses and procedures.

Galvanized steel, stainless steel, aluminum, steel, and copper alloy wire are all examples of the various wire kinds available. A number of parameters, including the intended usage, required tensile strength, durability, longevity, and required flexibility, are taken into account while deciding on the best wire to employ.

B:- Different Categories of Wire Mesh

1. Stainless Steel & alloy wire Meshes

The longevity and specialized design of these metal meshes are their primary selling points. In spite of being exposed to the harsh conditions of the shore, such wire meshes have shown to be durable and long-lasting.

These are the priciest choice, but they pay for themselves over time, especially with stainless steel wire meshes.

Some examples of alloys are copper alloys. There are many factors to think about when ordering custom wire meshes.

2. Vinyl Coated Wire Meshes

After being welded or woven, these wire meshes receive a PVC or polyester coating. Because of their versatility, these meshes can be rendered in whatever color the client desires; nevertheless, black and green are particularly popular because of their ability to disappear into their surroundings.

The metal wire mesh is sealed off from the elements and protected from rust and corrosion by the coating. These meshes come in a variety of quality levels and can be utilized in a wide variety of applications.

These have to be made from scratch because they are rarely sold commercially.

3. Galvanized Welded Wire Meshes

Welded steel mesh or iron Wire Mesh is then dipped in molten zinc to completely seal the welds and prevent corrosion. It prevents rust and corrosion and extends the life of the components, even when subjected to high temperatures.

This wire mesh will, of course, be more expensive, but it will prove to be a wise investment.

Most commonly, this wire mesh is used for animal cages, although it is also frequently used on ships (thanks to its resistance to seawater) and in other moist or humid environments.

4. Galvanized Woven Wire Meshes

This GI wire mesh is rust-proof since the zinc coating hasn't been burned off during the manufacturing process.

These offer a lower carbon footprint, greater mobility, and a longer service life. But there is an added cost for these as well. These wire meshes are typically used to create secure boundaries for wildlife enclosures or other facilities.

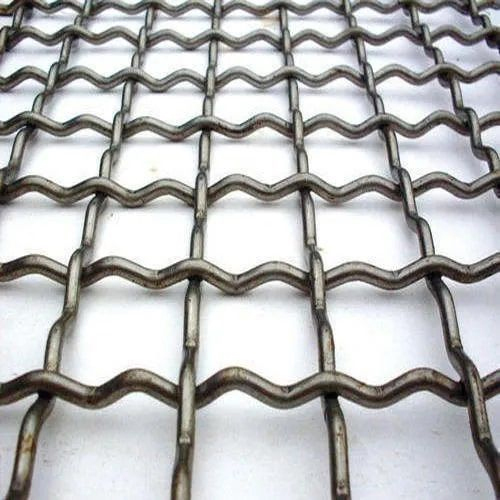

5. Double Weave Wire meshes

As an alternative to standard pre-crimped wire mesh, double weave wire mesh is available. By passing over and under two weft wires, the warp wires create a sturdy wire mesh design that can endure intense pressure.

Extra-sturdy wire mesh made with a double weave pattern is produced, finding use in a variety of settings, including as a base for vibrating screens in mining and crushing operations, as a barrier for livestock in agricultural settings, and as a divider between cooking areas in backyard grills.

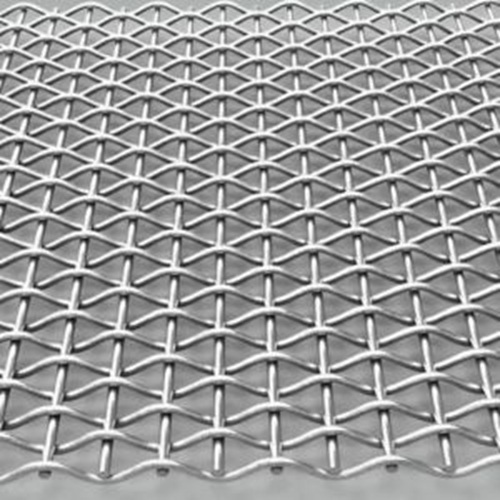

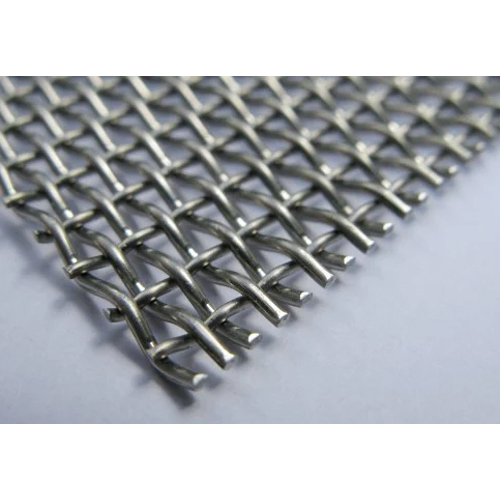

6. Twill Weave Wire Mesh

Wires with a larger diameter and more weight can be woven with greater ease using a twill weave pattern. Weaving warp wires over and under two weft wires, or at the point where a weft wire goes over and under two warp wires, creates the pattern.

To make a sturdy, rigid, and strong wire mesh, the warp wire is inverted at the intersections. This design evolves into a staggered series of parallel diagonal lines.

C: Manufacturing of Wire Mesh

Here are the manufacturing methods of wire mesh:

1. Wire Rod

Low carbon steel, sourced from a variety of steel producers, is used as the product's raw material. Carbon percentages in the raw materials range from 0.08 to 0.12, with the range covering the SAE 1008, SAE 1010, and SAE 1012 grades. The best raw materials are iron wire, galvanized iron wire, or stainless steel wire.

2. Cold Rolling

During the cold rolling process, metal is deformed by being fed through rollers at a temperature below its Recrystallization temperature.

By altering the crystal structure of the metal, cold rolling can boost its yield strength and hardness. These flaws both impede additional slide and diminish the metal's grain size.

3. Straightening & Cutting

The cutting and straightening equipment used comes from Italy. The coils of cold-rolled wire rods are fed into the straightening and cutting machine, where they are first automatically straightened, and then cut to a predetermined length (accuracy to within 2 milimeters).

There is a maximum size tolerance of 2mm for cutting the wire rods, which means they can be any length between 0.8 meters and 12 meters.

4. Welding

The wires that make up welded wire steel cloth are joined in square or rectangular grids by automatic welding machines.

Electric resistance is used to join the wires in a high-tech, fully-automated system that allows for fine-tuned control over welding conditions.

The dimensions and welding parameters can be set beforehand. The wires fuse together with the application of pressure, electrical current, and heat in a precisely calibrated sequence.

5. Warping and slicing

There are two distinct machines for cutting and bending available; both were manufactured in Schnell, Italy. The finished meshes are then trimmed to size using the cutting machine.

It's a motorized device that can make two or three cuts per second through mesh. The meshes that have been cut are then bent using the available bending equipment (as required by design).

The machine can bend sheet metal into virtually any shape (Up to 180o). The sheets needing cutting and bending will be taken for this operation, or the meshes will be taken immediately for shipment from the third process, according from the design requirements.

6. Finished Mesh

The next step in production is either galvanizing or PVC coating, which follows the bending or cutting processes.

D:- Advantages & Benefits of Wire Mesh

1. Can be colored as required

Wire mesh can be used to construct artistic facades by attaching steel plates in a configuration that generates a pattern, logo, or brand name. You can choose from a variety of colors, and some of them can even be covered with reflective film so that they stand out even in low light.

2. Use for artistic or business purpose

Wire mesh's airy, lacelike construction keeps people secure without compromising aesthetics or restricting natural light.

3. Lightweight and attractive design

Wire mesh systems can be used to construct animal enclosures, allowing for more space for the animals to move around in. A variety of wire meshes are available, each with their own unique size and aperture specifications.

4. Creates animal enclosures

Wire mesh can function as a wall to demarcate sections while still allowing light to pass through, making it a handy tool in cramped quarters.

5. Provides wall replacement systems

Wire mesh is great for fall safety and can support the weight of plants on big green walls because to its strength.

6. Effective in green facades

Wire mesh can be used to construct facade greening, offering a sturdy framework for plants to climb and flourish, which has both aesthetic and ecological benefits.

7. Provides fall protection

Fall protection on bridges, parking garages, balconies, and high pathways can all be made with wire mesh.

8. Durable, and low maintenance

Wire mesh, composed of marine-grade 316 stainless steel, is ideal for long-lasting construction projects due to its great strength and durability. And once it's up, wire mesh doesn't need much in the way of upkeep.

9. Flexible and malleable

Since wire mesh is so malleable, it may be "wrapped" around irregularly shaped objects with ease. This may be seen in places like playgrounds, sports fields, and parking garages, all of which have a vested interest in keeping their patrons safe.

FAQs: Wire mesh manufacturers

Q. What is wire mesh used for?

Ans. Wire mesh is used in a variety of applications, including filtering, sieving, sifting, and separating materials, as well as in construction, architectural design, and security.

Q. What are the top manufacturers of wire mesh?

Ans. Here are the top best manufacturers:

1. Tiger Wire Nets

2. Micro Wire Mesh Pvt.ltd

3. Fars Wiremesh

4. Rajfilters

5. Phifer

Q. What is the average price of wire mesh?

Ans. The going rate for 304 stainless steel wire mesh in India is roughly Rs 40 per sq ft.

Q. What is the use of wire mesh?

Ans. Wire mesh has several practical uses in commercial and domestic settings, including:

- Dog Cages

- Gutter Guards

- Security Screens

- Fencing

- Window Screens

- Bird Feeders

- Stairwell Screens

- Fireplace Screens

- Ventilation & more

Q. What are the different sizes of wire mesh?

Ans. The different Sizes of wire mesh include 0.0470 inch, 0.0800inch, 0.0630inch, 0.0200inch, 0.0280inch, 0.0090inch, 0.0075inch, 0.0100inch, 0.0065inch and more.

Q. What are the benefits of using wire mesh?

Ans. Wire mesh offers many benefits, including strength, durability, corrosion resistance, high temperature resistance, and more. It is also a cost-effective solution for many applications.

Q. How is wire mesh measured?

Ans. Wire mesh is typically measured by the number of wires per linear inch (WPI) or the number of openings per linear inch (OPI). This allows for easy comparison of different types of wire mesh.

Q. What are the different materials used to make wire mesh?

Ans. Wire mesh can be made from a variety of materials, including stainless steel, aluminum, brass, copper, and more. The choice of material depends on the specific application and the desired properties of the wire mesh.

Q. What are the different types of wire mesh?

Ans. There are many types of wire mesh, including welded wire mesh, woven wire mesh, perforated metal, expanded metal, and more. Each type has its own unique properties and is used for specific applications.

Q. Which wire mesh is best?

Ans. The best wire mesh for a particular application will depend on the specific requirements of that application. Some of the factors that should be considered when choosing a wire mesh include the material it is made from, the size and shape of the mesh openings, the thickness of the wires, and the strength and durability of the mesh.

Some common wire meshes are:

- Stainless steel wire mesh: This is a popular choice for many applications due to its strength, corrosion resistance, and high temperature resistance.

- Aluminum wire mesh: This is a lightweight, corrosion-resistant option that is often used in architectural and decorative applications.

- Brass wire mesh: This is a strong, corrosion-resistant wire mesh that is often used in filters and sieves.

- Copper wire mesh: This is a corrosion-resistant wire mesh that is often used in chemical and electrical applications.

It is also important to consult with a professional in the field or the manufacturer for the best recommendation for your particular application, as there are many different types of wire meshes available and each one has its own unique properties.

Q. What is the basics of wire mesh?

Ans. The basics of wire mesh include:

-

Material: Wire mesh can be made from a variety of materials, including stainless steel, aluminum, brass, and others.

-

Weaving: The wires or fibers that make up wire mesh are woven together to create a grid-like pattern. There are various weaving methods, including plain weave, twill weave, and Dutch weave.

-

Mesh size: The mesh size refers to the number of openings per inch in the wire mesh. It affects the wire mesh's permeability and its ability to filter out particles.

-

Wire diameter: The diameter of the wires or fibers in wire mesh affects its strength, durability, and suitability for different applications.

-

Tensile strength: The tensile strength of wire mesh refers to its ability to resist breaking under tension.

-

Applications: Wire mesh has a wide range of applications, including screening, filtering, reinforcing, and fencing.

-

Standard specifications: Wire mesh is manufactured to various standard specifications, such as ASTM, ISO, and DIN, to ensure its quality and consistency.

Q. What are wire mesh sizes?

Ans: Based on their end use, the wire mesh can be acquired as roll goods or discrete invented to size parts. Based on the application you can choose your size.

Q. What are the special physical properties of wire mesh?

Ans: The mesh has excellent thermal as well as electrical conductivity. In addition, it is bendable and ductile. This is suited for several electrical applications and works against radio frequency meddling. Most of them are of high strength, with the possibility to be cladded or galvanized with PVC coating. In addition, their robustness can be intensified if they are painted. Mesh, which is fabricated from stainless steel wires, does not need any further surface treatment.

If you are buying one, be sure of its primary physical features such as finer wire openings, mechanical stability, and remarkably high tensile strength.

Q. Is wire mesh a conductor?

Ans: A heavy-duty wire metallic mesh is highly conductive. It is a good conductor of electricity, thermal heat, and magnetic flux.

Q. What is the load capacity of a wire mesh?

Ans: Commonly, the load capacity is between 1500 lb to 2500 lb.

Normally, industrialists are rating these gears for safety at 1500 lb to 2500 lb, load capacity. The results of the mesh are based on several factors such as thicknesses, shape and quantity of bars, the width, the wire gauge, etc.

Q. Which wire mesh is best?

Ans: Out of all the mesh formations, stainless steel wire mesh is the best. It is renowned for its sturdiness, dependability, and longevity. It is totally safe for outdoor application as it has high resistance to rust. In addition, the mesh has high durability and strength, making it suitable for all large-scale industrial projects.

The wire mesh of aluminum provides better heat conductivity than steel ones.

The rest depends on your application requirements.

Q. What to look for when buying wire mesh?

Ans: There are some crucial tips that all must consider before buying one;

- The purpose for which you need a wire mesh has an important role. All types have different advantages and disadvantages and you must choose the one as per your need.

- The process of fabrication is also an important area to look at, as it makes an impact on the structural rigidity, durability, and tensile strength of the mesh.

- Pattern and size have a crucial role in fulfilling industry-specific filtration requirements. The wire meshes must be chosen for higher precision filtration and not get confused with other variants.

- The alloy type and sintered metal have a role too in your wiser selections based on the environment, temperature, and nature of the application.

- Make use of non-corrosive metals if the applications are in the water, mining, and oil industry. If the meshes are to be used at extreme temperatures, metals need to be extremely resistant to erosion.

- The thicker the cable, the more robust and stronger the mesh is. On the other hand, the thicker ones will reduce the open area.

READ BLOG: Best Quality Top 10 Wire Mesh Manufacturers, Suppliers, Exporters In India

Manufacturers & Suppliers of Wire Mesh

Company Name | Member Since |

|---|---|

International Wirenetting Industries Palghar, India | 21 Years |

Precise Alloys Pvt. Ltd. Mumbai, India | 18 Years |

Virendera Textiles Noida, India | 17 Years |

Hmb Engineering Ghaziabad, India | 17 Years |

Ocean Non Wovens Pvt Ltd Jhajjar, India | 12 Years |

Indo German Wire Screen Co. Mumbai, India | 11 Years |

Kiran Wirenetting Stores Kolkata, India | 11 Years |

Gaylord Enterprise Ahmedabad, India | 11 Years |

United Filters Industries Pvt Ltd. Pune, India | 11 Years |

Dharam Shree Enterprises Delhi, India | 10 Years |

Popular Products