Attritor Mill By S. F. Engineering Works

Price:

Get Latest Price

In Stock

Product Overview

Key Features

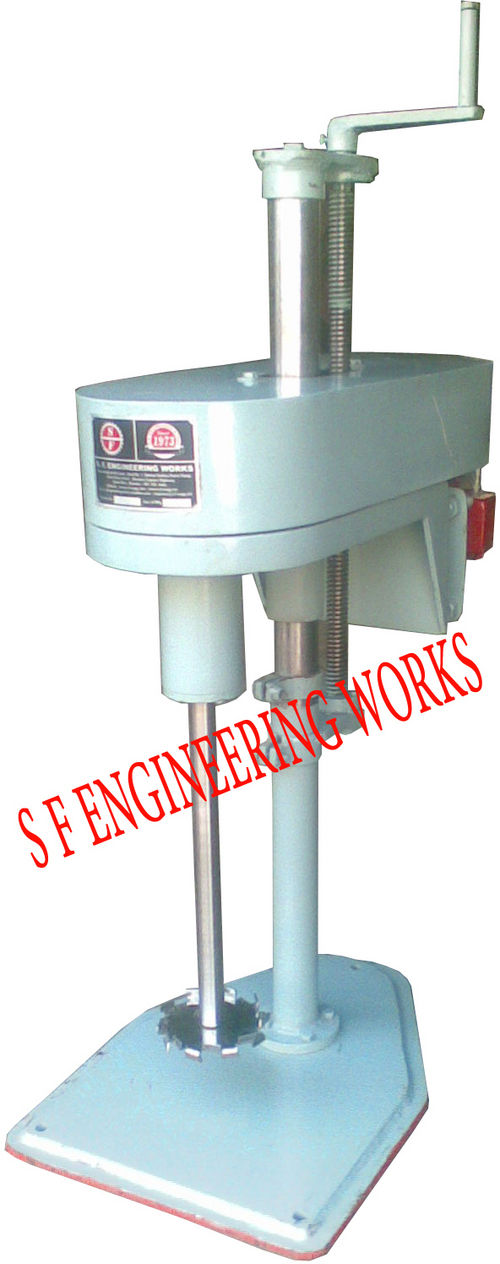

ATTRITOR

ATTRITOR:

Attrition Mills, Also Called Stirred Ball Mills, Are A Very Fast, Powerful And Efficient Method For All Operations Of Grinding, Blending And Milling, Either Wet Or Dry. The Advantage Of An Attrition Mill Is That It Ensures That All The Grinding Media Are In Action All The Time. This Results In Much Faster Action. For Example, Wet Milling A Casting Slip Can Be Completed In One Tenth Of The Milling Time Required In A Conventional Ball Mill.

Advantages of Using a Batch Attritor:

A a A A. Ten times faster than ball mills

A a A A. Minimum maintenance required

A a A A. Simple to operate

A a A A. Rugged construction

A a A A. Energy efficient

A a A A. Compact design

A a A A. No premixing required

A a A A. No special foundation necessary

A a A A.

Applications for Attritors:

Paints, toners, inks

Ceramics

Agricultural flowables

Food products

Chocolate, confectionery

Paper coatings, calcium carbonate, clay

Chemicals

Ferrites

Metal oxides

Minerals, ores, coal

Sulphur dispersions

OPERATING PRINCIPAL:

A a A A. Machine Operates According To The Principle Of An Agitator Bead Mill. The Vertically Arranged Special Agitator Is Equipped With Agitator Pegs.

A a A A. Ideal Flow Conditions Are Reached Through The Combination Of Optimally Arranged Agitator Pegs And The Hemispherical Grinding Chamber Floor.

A a A A. Circulation Grinding Guarantees An Exact Reproducibility And High Product Homogeneity|

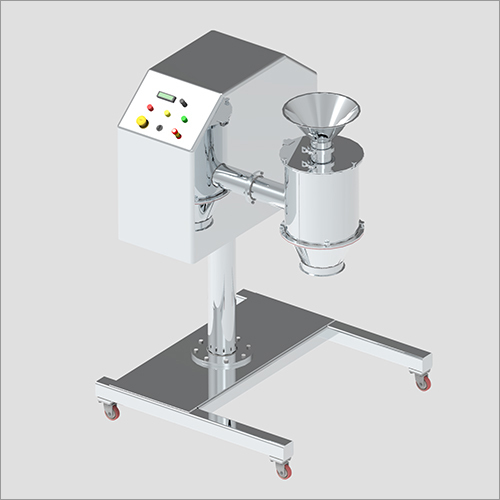

WORKING OF ATTRITOR:

The Attritor is often referred to generically as a "stirred ball mill /Grinding and Dispersing EquipmentA AcAca A A A The operation of an Attritor is simple and effective. The material to be ground and the grinding media are placed in a stationary, jacketed tank. This media is spherical measuring 3/32" to 3/8" in diameter. Commonly used types of media are carbon steel, stainless steel, chrome steel, tungsten carbide, ceramic, or zirconium oxide.

The material and the media are then agitated by a shaft with arms, rotating at high speed. This causes the media to exert both shearing and impact forces on the material, resulting in optimum size reduction and dispersion.

No premixing is necessary. The material can be directly fed into the jacketed grinding tank of the Attritor. Those portions of the formulation requiring only slight grinding can be easily added later.

The Final Result Of This Remarkably Efficient Process Is An Extremely Fine Material, Measured In Microns Or Fractions Of Microns, Distributed On A Very Narrow Curve. The Laboratory Attritor Works Up To Ten Times Faster Than The Conventional Ball, Pebble Or Jar Mill. Its Compact, Vertical Profile Requires Minimal Space. No Premixing Is Necessary. Adding Ingredients (Or Taking Samples) Can Be Done At Any Time During The Grinding.

Production batch Attritors are equipped with a built-in pumping system that maintains circulation during grinding for accelerated attrition and uniformity. This pump can also be used for material discharging. The final result of the grinding action is a fine, even particle dispersion.

Batch Attritors offer the advantage that the material can be inspected any time during the grinding cycle. Therefore, adjustments or formulation additions can be accomplished without stopping the machine.

CONSTRUCTION:

The Vessel Is Made From Thick S.S.304. Material To Withstand Heavy Loads And Is Provided With A Top Cover In Two Halves Which Can Be Locked On To The Main Vessel By Means Of Eye Bolts. A Jacket In M.S. Construction For Heating And Cooling Is Provided Complete With Inlet Outlet And Drain Fittings. Cooled Chamber And Product Pipeline. A Specially Designed Ball Valve With Strainer Is Provided At The Bottom Of The Vessel For Quick Discharge Of The Material. The Complete Vessel Is Mounted On Steel Shaft Perfectly Balanced And Housed On The Frame Structure. The Entire Vessel Can Be Tilted By Means Of A Mechanical Device To Facilitate Cleaning Operations. Residue-Free Discharge And Easy Cleaning Due To Dish Bottom Chamber. The Main Shaft Is Connected To The Output End Of The Gear Box Assembly By Means Of C.I./M.S. Rigid Flange Type Coupling. The Shaft Is Carefully Machined And Fitted With Specially Designed Adjustable Attrition Arms Which Rotate At 120 RPM. The Unit Is Painted With 2 Coats Of Metal Primer And 2 Coats Of Synthetic Enamel Paint.

ELECTRICALS: All Electrical Are 3 Phases, 50 Cycles, and 400 V.

PANEL: The Machine Is Complete With An Electrical Panel Consisting Of Ammeter, Voltmeter And A AcAca A A a ON/OFFA AcAca A A A Switches.

DRIVE: The Drive Unit Is Enclosed In Steel Cabinets Supported And Stiffened By Structural.

USEFUL TIPS:

A useful and simple equation describing the grinding momentum is M x V (mass x velocity), which enables us to see how the Attritor fits into the family of mills. For example, ball mills use large media, normally 1/2" or larger, and run at a low (10-50) rpm. The other mills, such as sand, bead, and horizontal, use smaller media (from 1/64" to 1/8"), but run at a very high rpm (roughly 800-1200). High-speed dispersers with no media run even faster (1200-1800) rpm, with tip speeds of 5000-6000 fpm. The Attritor falls mid-range between these, using 1/8" to 3/8" media, agitating at moderate speeds from 60 rpm in the largest production size units, to 300 rpm for the laboratory size units (with tip speeds of 600-1000 fpm). The most important concept in the Attritor is that the power input is used directly for agitating the media to achieve grinding and is not used for rotating or vibrating a large, heavy tank in addition to the media.

Description

SFA 5

SFA 25

SFA 50

SFA 100

SFA200

SFA 300

SFA 500

SFA 1000

SHELL THICKNESS

6 mm

6 mm

6 mm

6 mm

6 mm

6 mm

6 mm

6 mm

Tank Vol LTS

5

25

50

100

200

300

500

1000

Slurry Vol LTS

2.4

12

24

50

100

145

225

450

Media Kgs

5

24

45

90

180

275

450

900

Motor HP

1

3

5

7.5

15

20

25

50

Agitator RPM

145

130

130

125

110

110

105

105

Fluid Coupling

ABSENT

ABSENT

ABSENT

ABSENT

PRESENT

PRESENT

PRESENT

PRESENT

Floor Space

38 X 80

41 X 86

51 x 103

60 x 136

76 x 159

83 x 170

120 x 210

140 x 235

W x D

cms

cms

cms

cms

cms

cms

cms

cms

**Features variable speed drive motor

***Varies according to motor HP.

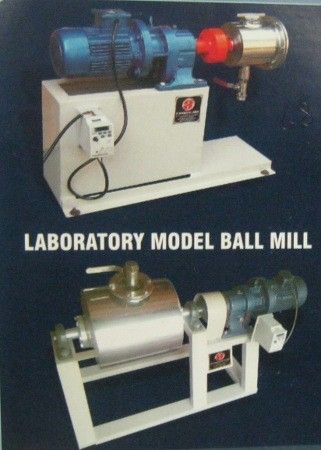

Laboratory Ball MillsHow to Select the Right Mill for Your Needs

Having a laboratory mill on your premises offers a number of advantages, but you need the right equipment to get the most benefit from your investment.

When evaluating lab mills, you should keep in mind the following considerations:

Speed

Efficiency

Batch size

Material

Starting particle size

Target particle size

Process mode (wet, dry, circulation, batch, continuous)

Scale-up capability

Ease of operation

Repeatability

Flexibility

Ease of taking samples

Ease of making formulation adjustments

Number of options

Low need for maintenance

In many instances, the right choice is an Attritor (sometimes referred to as a stirred ball mill). With an Attritor, the material to be ground is placed in a stationary tank with the grinding media, which are agitated by a shaft with arms rotating at high speed. Click here for information on how the material used to make your Attritor can affect your project.

Working up to 10 times faster than conventional laboratory ball mills (sometimes referred to as jar mills or pebble mills), the lab Attritor has a compact, vertical profile, requiring minimal space, and can be equipped or retrofitted easily and inexpensively with a variety of components and accessories.

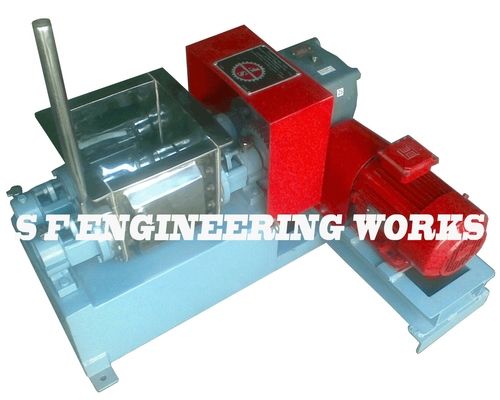

WET GRINDING BATCH MODE LABORATORY ATTRITOR

Laboratory Attritor:

S.Fcustomers know from experience that the Attritor is one of the most versatile pieces of equipment in their lab. It can be equipped or retrofitted easily and inexpensively with a wide variety of components and accessories. With the Attritor, users can choose wet or dry grinding, introduce inert atmospheres, operate at controlled temperatures, vary grinding speed, overcome product contamination, change media size and type, and get precise energy consumption information, all on the same machine. Results are repeatable from one test grind to another for maximum credibility. Finally, the Attritor is ideal for formulating, quality control, and scale- up studies.

Advantages of Using a Laboratory Attritor:

Fast and efficient grinding

Numerous options

Flexibility

Repeatability

Scale-up capability

No premixing

Easy operation

Low maintenance

Common Applications for Attritors:

High tech ceramics

Paints, toners, inks

Pigments

Tungsten carbides

DSM (mechanical alloying)

Food products

Chocolate, confectionery

Pharmaceuticals

Chemicals

Ferrites

Fibers

Paper coatings

Metal powders

Metal oxides

Glasses

Glazes

Minerals, coal

Agricultural flowables

Optional Features of Laboratory Model Attritors

Variable speed drive motor for different RPM selections (0-3000)

Adjustable agitator shaft height to accommodate different size grinding media

Bottom discharge grid with valve for easy sampling and discharge

Tank tips to 90A a A A for media discharge and fast cleaning

Jacketed stainless steel (304/316) tank for heating and cooling

Stainless steel (304) shaft with 440 C stainless steel arms

Tachometer

Quick-disconnects for cooling water

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

1973

Working Days

Monday To Sunday

GST NO

27ARUPS7370Q1ZE

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

Seller Details

GST - 27ARUPS7370Q1ZE

Mira Bhayandar, Maharashtra

Proprietor

Mr Fayazulla Z. Sayed

Members since

21 Years

Address

SHANTA INDL. ESTATE, SHED NO-1, BEHIND DODHIA PETROL PUMP, W.E. HIGHWAY, KASHIMIRA-MIRA ROAD, Mira Bhayandar, Maharashtra, 401104, India

attritor mill in Mira Bhayandar

Report incorrect details