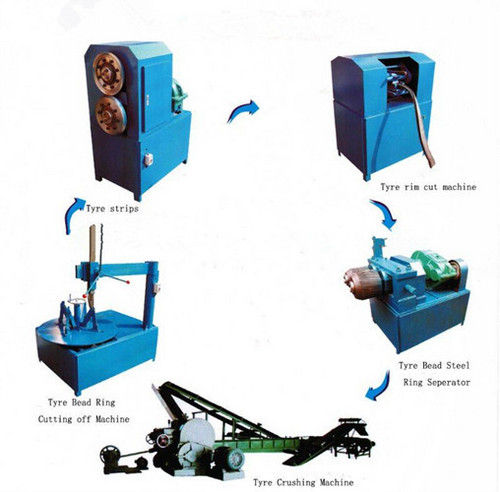

Automatic Feeding And Safety Waste Tire Recycling Machine

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Safety:

1. Professional sealing technology for cover, oil outlet.

2. Heavy oil is separated which can avoid the problems of jam in later condensing.

3. Vacuum system will prevent exhaust gas from going back to reactor and causing accident.

4. Alarm, safety valves, thermometer, pressure gauge and safety valve.

5. It is dangerous to burning exhaust gas (C1 to C4). In our process, it is transferred first through the safety device and a safety burning air muzzle. Before burning, we should ensure the safety of production.

1) Overview of pyrolysis plant

The whole pyrolysis system is composed by 13 parts, which are reactor, transmission device, catalytic chamber, cooling tube, heavy tank, oil-water separator, condenser, light oil tank, safety device, vacuum system, dedusting system, draft fan, chimney.

Cooling systems decides oil output. There are two steps for cooling. Cooling pipe is the first step. The second is condenser. We have three condensers. And there are 57 pipes in one condenser. Diameter is 48mm for one small pipe. The heat exchanging area is about 13square meters for one condenser. So the total cooling area is about 40 square meters, which will guarantee you a high oil yield.

Company Details

Focusing on a customer-centric approach, Xinxiang Doing Eenwable Energy Equipment Co;Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Get Tyres Repair & Retreading Machinery from Xinxiang Doing Eenwable Energy Equipment Co;Ltd at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier, Trading Company

Establishment

2001

Related Products

Explore Related Categories

Seller Details

Xinxiang, Henan

Angela Li

Address

Industrial zone ,Nanhuan Road ,Xinxiang City ,Henan provice, China Xinxiang, Henan, 453000, China

recycling machines in Xinxiang

Report incorrect details