Product Overview

Key Features

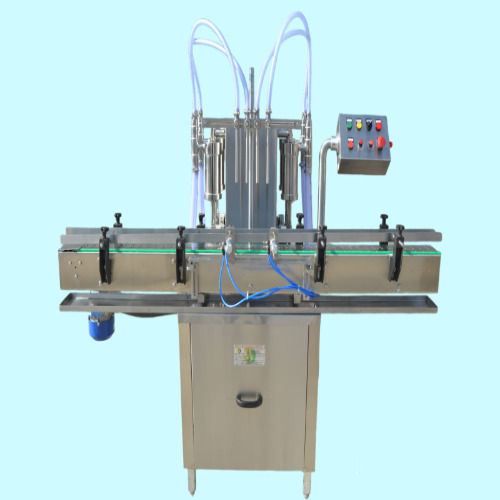

<p><u><strong><span style="font-weight: bold;">AUTOMATIC FOUR HEAD VIAL FILLING MACHINE</span></strong></u></p><p> </p><table width="700" cellspacing="0" cellpadding="0" border="0" align="center"><tbody><tr><td valign="top" align="left" class="maintxt"><strong>LAXMI</strong>

Automatic Volumetric Vial Liquid Filling Machine. The Basic Unit

Consists Of One side Turn Table, S.S. Slat Conveyor Belt, Unique Co-

eccentric Simultaneous Gassing with Filling.. The Machine Has an Output

Speed of 100 Vials per Minute but Depending upon the Fill Volume and

Container Dia. /size Or the Quality & Viscosity of Liquid.</td>

</tr>

<tr>

<td valign="top" height="10" align="left"><br /></td>

</tr>

<tr>

<td height="30" background="images/bg_image.png" align="left" class="style2"><span class="style1">Silent Feature</span> :</td>

</tr>

<tr>

<td valign="top" height="10" align="left"><br /></td>

</tr>

<tr>

<td valign="top" align="left"><table width="100%" cellspacing="0" cellpadding="0" border="0" align="center">

<tbody>

<tr>

<td width="10" valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">All Liquid Contact Parts are of S.S. 316, the Body Structure is built up of S.S. 304 Pipe.</td>

</tr>

<tr>

<td valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">Co- Eccentric Nozzles allows Very Quick and precise Filling of liquid with Simultaneous nitrogen flushing.</td>

</tr>

<tr>

<td valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">No Vail– Machine stops system</td>

</tr>

<tr>

<td valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">Minimum Change over time, from one spare to another</td>

</tr>

<tr>

<td valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">Each individual part that is required for autoclaving can be mantled and dismantled very easily.</td>

</tr>

</tbody>

</table></td>

</tr>

<tr>

<td valign="top" align="left"> </td>

</tr>

<tr>

<td valign="top" align="left"><table width="100%" cellspacing="1" cellpadding="5" border="0" bgcolor="#c7c7c7" align="center">

<tbody>

<tr>

<td valign="middle" height="30" bgcolor="#404040" align="center" colspan="2" class="style2"><strong>TECHNICAL SPECIFICATION</strong></td>

</tr>

<tr>

<td width="43%" valign="middle" height="25" bgcolor="#ebebeb" align="left" class="client_list_txt"><strong>Model No</strong></td>

<td width="57%" valign="middle" bgcolor="#ffffff" align="left" class="client_list_txt">LVFT 100</td>

</tr>

<tr>

<td valign="middle" height="25" bgcolor="#ebebeb" align="left" class="client_list_txt"><strong>Filling Heads</strong></td>

<td valign="middle" bgcolor="#ffffff" align="left" class="client_list_txt">2 Head, 4 Head, 6 Heads, 8 Head & 12 Head</td>

</tr>

<tr>

<td valign="middle" height="25" bgcolor="#ebebeb" align="left" class="client_list_txt"><strong>Output/ Hour</strong></td>

<td valign="middle" bgcolor="#ffffff" align="left" class="client_list_txt">1200 to 1500 Vial Per Head (Depending on the nature of liquid and its fill size or volume)</td>

</tr>

<tr>

<td valign="middle" height="25" bgcolor="#ebebeb" align="left" class="client_list_txt"><strong>Power Characteristics</strong></td>

<td valign="middle" bgcolor="#ffffff" align="left" class="client_list_txt">230v 1 Phase 50Hz 4 Wire System</td>

</tr>

<tr>

<td valign="middle" height="25" bgcolor="#ebebeb" align="left" class="client_list_txt"><strong>Input (Container Dia/ Height)</strong></td>

<td valign="middle" bgcolor="#ffffff" align="left" class="client_list_txt">16mm Dia to 50mm Dia/ Height 75mm Max.</td>

</tr>

<tr>

<td valign="middle" height="25" bgcolor="#ebebeb" align="left" class="client_list_txt"><strong>Fill Volume</strong></td>

<td valign="middle" bgcolor="#ffffff" align="left" class="client_list_txt">0.1 ml to 50ml</td>

</tr>

<tr>

<td valign="middle" height="25" bgcolor="#ebebeb" align="left" class="client_list_txt"><strong>Filling Accuracy</strong></td>

<td valign="middle" bgcolor="#ffffff" align="left" class="client_list_txt">±1 %</td>

</tr>

<tr>

<td valign="middle" height="25" bgcolor="#ebebeb" align="left" class="client_list_txt"><strong>Net Weight </strong></td>

<td valign="middle" bgcolor="#ffffff" align="left" class="client_list_txt">350 kgs</td>

</tr>

<tr>

<td valign="middle" height="25" bgcolor="#ebebeb" align="left" class="client_list_txt"><strong>Turn Table</strong></td>

<td valign="middle" bgcolor="#ffffff" align="left" class="client_list_txt">600mm</td>

</tr>

<tr>

<td valign="middle" height="25" bgcolor="#ebebeb" align="left" class="client_list_txt"><strong>Machine Length </strong></td>

<td valign="middle" bgcolor="#ffffff" align="left" class="client_list_txt">4400mm</td>

</tr>

<tr>

<td valign="middle" height="25" bgcolor="#ebebeb" align="left" class="client_list_txt"><strong>Machine width</strong></td>

<td valign="middle" bgcolor="#ffffff" align="left" class="client_list_txt">800mm/ 1600mm (Apro)</td>

</tr>

<tr>

<td valign="middle" height="25" bgcolor="#ebebeb" align="left" class="client_list_txt"><strong>Machine height </strong></td>

<td valign="middle" bgcolor="#ffffff" align="left" class="client_list_txt">1700mm</td>

</tr>

</tbody>

</table></td>

</tr>

<tr>

<td valign="top" height="10" align="left"><br /></td>

</tr>

<tr>

<td height="30" background="images/bg_image.png" align="left" class="style2"><span class="style3"><strong>Application</strong> :</span></td>

</tr>

<tr>

<td valign="top" height="10" align="left"><br /></td>

</tr>

<tr>

<td valign="top" align="left"><table width="100%" cellspacing="0" cellpadding="0" border="0" align="center">

<tbody>

<tr>

<td width="10" valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">Pharmaceuticals</td>

</tr>

<tr>

<td valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">Ayurvedic</td>

</tr>

<tr>

<td valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">Herbal</td>

</tr>

<tr>

<td valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">Pesticide</td>

</tr>

<tr>

<td valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">cosmetic</td>

</tr>

<tr>

<td valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">chemicals</td>

</tr>

<tr>

<td valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">Food</td>

</tr>

<tr>

<td valign="baseline" height="20" align="left"><img width="10" height="9" border="0" src="http://laxmipharmaequipments.com/images/bullet1.jpg" /></td>

<td height="20" align="left" class="maintxt">And in other allied company and industries</td></tr></tbody></table></td></tr></tbody></table><p> </p>

Disclaimer

The contents on this website is provided solely for informational purposes and is not intended to be a substitute for professional medical advice, diagnosis, or treatment. If you have any questions about a medical problem, please consult a physician or other authorized health expert. Do not dismiss or postpone getting competent medical advice because of something you read on this website.

LAXMI PHARMA EQUIPMENT, Established in 1985 at Ahmedabad in Gujarat, is a leading Exporter,Manufacturer,Supplier,Wholesaler of Pharmaceutical Machinery in India. LAXMI PHARMA EQUIPMENT is one of Trade India's verified and trusted sellers of listed products. With extensive experience in supplying and trading undefined, LAXMI PHARMA EQUIPMENT has made a reputed name for itself in the market with high-quality 1 Head Auger Powder Filling and 1 Head Capping Machine, 1 Head Auger powder Filling and 1 Head Capping Machine, 1 Head Ropp/Screw Capping Machine, etc.

Focusing on a customer-centric approach, LAXMI PHARMA EQUIPMENT has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pharmaceutical Machinery in bulk from LAXMI PHARMA EQUIPMENT at Trade India quality-assured products.