Product Overview

Key Features

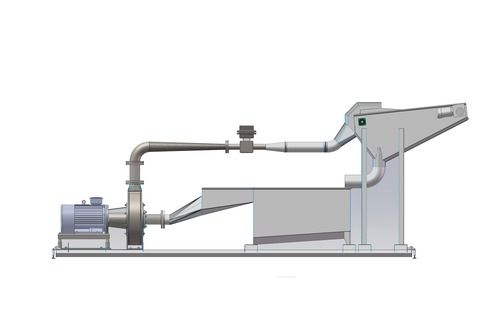

The hydro cutting line is composed of a pump, conveying pipes and a cutter module. It can split the goods into strips, slices, wedges or other possible shapes. With the characteristics of fast cutting speed, low process loss, quickly cutter switching, and flexible line assembly, it also can be used to soak and clean goods during long-distance transportation.

Shandong Sensitar Machinery Manufacturing Co., Ltd., was built up and put into operation in May, 2014. It focuses on the R&D and manufacturing of complete food production line, potato peeling and cutting line and French fries production line. The company has two production bases, covering a total area over 120 mu, a workshop area over 40000 square meters and more than 180 employees. Closely following the development trend of global cutting-edge science and technology and collecting the knowledge of world food process, the full production lines manufactured by the company has the characteristics of high automation and low labor intensity, so as to achieve a result of simplification, continuity and energy saving during production.

In order to better improve the user experience and product performance, the company introduced advanced equipment and production concepts from developed countries such as Europe and the United States, passed through the ASME certification, and worked closely with industry leaders at home and abroad to successively develop steam peeler and water cutting line, which solved the problems of large-scale and automation faced by the potato processing industry, to improve production efficiency and production yield significantly.