- Tradeindia

- Strapping Machines

- Automatic Strapping Machine

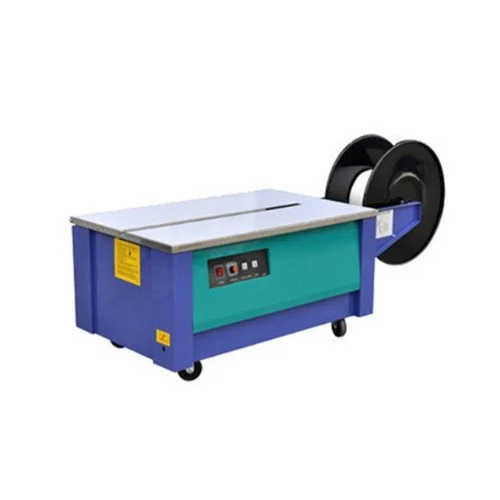

Automatic Strapping Machine

(707 products)Box Strapping Machine - Mild Steel, 900*570*735 mm | Automatic Operation, Uniform Tensioning, 1-Year Warranty, Ideal for Cartons and Containers

70000.0 INR/Unit

MOQ1 Piece/Pieces

ColorGreen

UsageIndustrial

MaterialMild Steel

Size900*570*735 mm

Height735 Millimeter (mm)

ComputerizedNo

View More

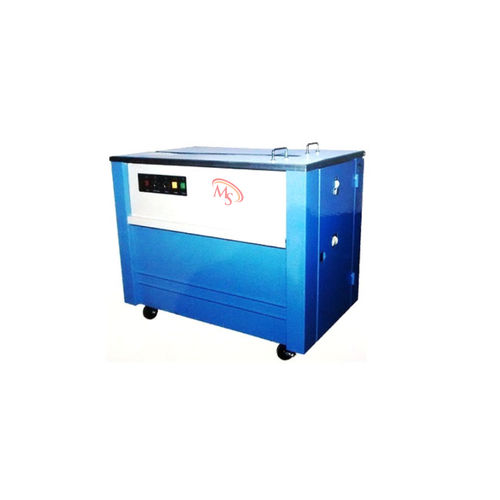

Automatic Box Strapping Machine Mb 1 Features - Color: Blue

Price : 320000.00 INR

Automatic Box Strapping Machine - Stainless Steel, 900x570x735 mm, Green | Frequency Speed Control, Adjustable Tension up to 45 kg, 1.5 Sec Cycle Time, Portable Design

Price : 69500.0 INR

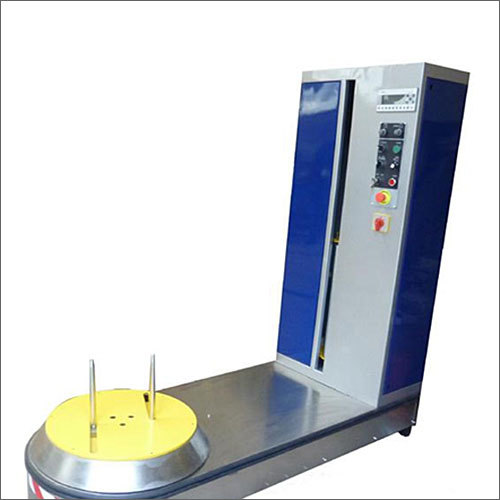

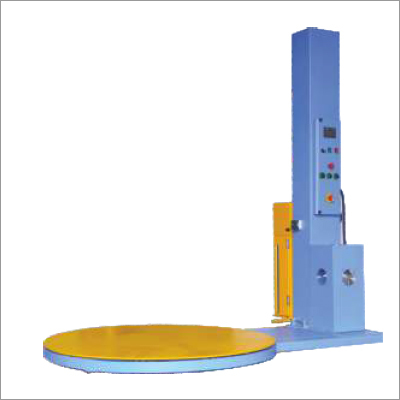

Pallet Stretch Wrapping Machine - Metal, Adjustable Height, Variable Speed Turntable | Yellow/Grey Color, Semi-Automatic, Up to 30 Loads Per Hour

Price : 5,50,000 INR

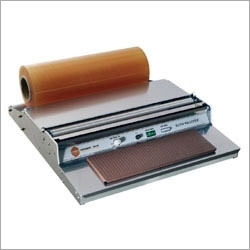

Automatic Commercial Grade Shrink Wrapping Machine

Price : 50000.00 INR

Shrink Chamber Wrapping Machine - Automatic Grade: Automatic

Price : 44000 INR

Fully Automatic Strapping Machine - Color: Blue Paint Coated

MOQ1 Unit/Units

MaterialMetal

Automatic GradeAutomatic

Control SystemHuman Machine Interface

ColorBlue paint Coated

Weight (kg)Differ as per size Kilograms (kg)

WarrantyYes

DURAPAK Strapping Machines

ColorBlue

MaterialAluminum Alloy

DimensionsVariable

Speed2.4 Sec/Cycle

Tension90+ Kgs

FeaturesFast Strapping, Easy Operation, Low Maintenance, Precise Strapping, Durable Design, Adjustable Tension, Cost-Effective, Versatile Use

View More

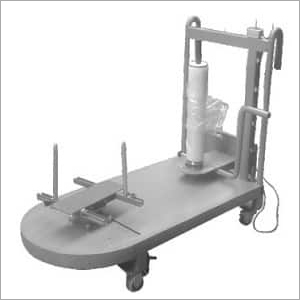

Cling Wrapping Machines

Get Best Deal

High Speed Automatic Stretch Wrapping Machine - Color: Sliver

Price : 850000 INR

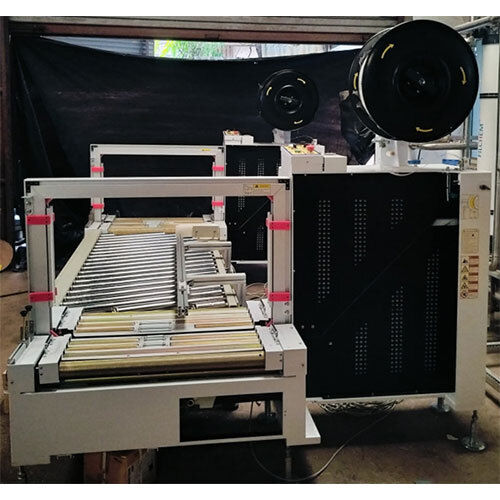

Carton Stretch Wrapping Machines - Automatic Grade: Automatic

Price : 120000 INR

Horizontal Stretch Wrapping Machines - Automatic Grade: Automatic

Price : 600000 INR

Fully Automatic Strapping Machinery - Max Strap Size 800x600 mm, Min Strap Size 80x50 mm, Strapping Speed 2 Sec, Strapping Force 25-700 N, Work Table Height 830 mm, 1.2 HP Power Source

Max Strap Size800X600 mm

Min Strap Size80X50 mm

Strapping Speed2 sec

Strap Width9-15 mm

Strapping Force25-700 N

Working Table Height830 mm

Shri Vinayak Packaging Machine Pvt. Ltd.

New Delhi

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller21 Years

View More

Pallet Strapping Machine - Stainless Steel, 900x580x500 mm, Blue | Automatic Operation, 1.5 m/s Strapping Speed, 120 kg Weight, Minimal Maintenance

Price Trend : 62000.00 - 125000.00 INR

Semi-Automatic Sp-740H Semi Auto Strapping Machine

Get Best Deal

Semi Low Table Top Strapping Machine - Metal, 900x580x500 mm, 450 Strapping Force | Semi-Automatic Operation, High Packaging Speed

Price Trend : 35000.00 - 63000.00 INR

Dba200 Automatic Strapping Machine - Color: Black

MOQ1 Unit/Units

TypeStrapping Machine

MaterialMild Steel

Automatic GradeAutomatic

ColorBlack

Weight (kg)215 Kilograms (kg)

WarrantyYes

Fully Automatic Box Strapping Machine - 1390 x 640 x 1525 mm, Black | High-Speed Strapping 25-30 Straps/Min, Aluminum Alloy Arch, Low Maintenance

Price: 220000.00 INR/Piece

MOQ1 Piece/Pieces

ColorBlack

TypeBox Strapping

Automatic GradeAutomatic

Selection ModeAutomatic

Dimension (L*W*H)1390 x 640 x 1525 Millimeter (mm)

Vijay Enterprise

Kolkata

Trusted Seller

Trusted Seller Super Premium

Super Premium Super Seller

Super Seller15 Years

View More

Carton Strapping Machine - Adjustable Strap Width 6-15 MM, 1.5 Secs/Cycle Speed, Semi-Automatic, Computerized, 90 kg, Heat Sealed, Blue & White

Price : 42000 INR

Automatic Strapping Machine - Dimension (L*W*H): 1580 X 620 X 1420 Millimeter (Mm)

Price : 360000.00 INR

Semi-Automatic Box Strapping Machine - Color: Green

Price: 34000 INR/Unit

MOQ1 Unit/Units

TypeSemi-Automatic Box Strapping Machine

MaterialMild Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Dimension (L*W*H)910*580*730 Millimeter (mm)

ColorGreen

Shiv Packaging

Ahmedabad

Trusted Seller

Trusted Seller Super Premium

Super Premium Premium Seller

Premium Seller4 Years

View More

Low Table Strapping Machine - Cast Iron Material, 95 kg Weight, 5 SPM Capacity, Semi-Automatic Operation, White Color, 1 Year Warranty

Price : 33000 INR

Box Strapping Machine - Automatic Grade: Semi-Automatic

Price : 33000 INR

Semi Automatic Strapping Machine - MS Material, Semi-Automatic Grade, Sleek White Color | Human Machine Interface Control, 1-Year Warranty

Price : 45000 INR

Automatic Single Phase Box Strapping Machine

Price : 28000 INR

Bottom Seal Automatic Strapping Machines - Color: Blue & White

Price: 475000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue & White

TypeBottom Seal Automatic Strapping Machines

MaterialSteel

ComputerizedNo

Warranty1 Year

View More

Automatic Strapping Machine (A-93AR)

Get Best Deal

Automatic Strapping Machine (A-93Y)

Get Best Deal

Carton Wrapping Machine - Automatic Grade: Semi-Automatic

Price : 150000 INR

Fully Automatic Strapping Machine - Capacity: 300 Kg/Hr

Price: 195000.00 INR/Unit

MOQ1 Unit/Units

ColorBlue

TypeStrapping Machine

Materialss

Auxiliary Packaging Machine TypeOther

ComputerizedNo

Automatic GradeAutomatic

Smart Packaging System

Indore

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller10 Years

View More

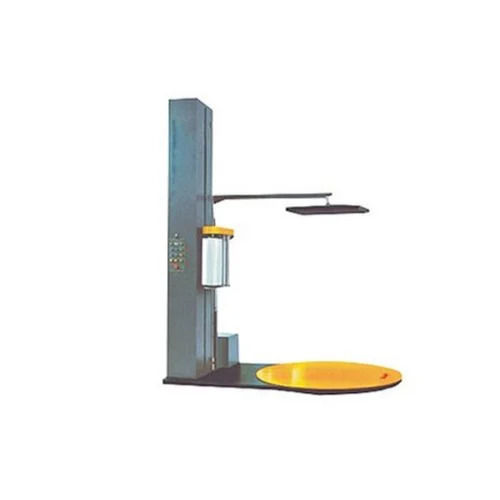

Pallet Stretch Wrapping Machine - Stainless Steel & Mild Steel, Grey Color | 1 Year Warranty, Semi-Automatic Functionality, Voltage Range 120-440

Price : 310000 INR

Shrink Chamber Wrapping Machine - MS & SS, 15x20 inches, Other Color | 1 Year Warranty, Semi-Automatic, Compatible with PVC, PP, POF

Price : 60000 INR

Battery Powered Pet Strapping Machine - Automatic Grade: Manual

Price : 85000.00 INR

Automatic Strapping Machine - Power: 440V 3 Phase

MOQ1 Unit/Units

Product TypeOther, Automatic Strapping Machine

Power SourceElectricity

Operating TypeAutomatic

Power440V 3 Phase, 50 hz Volt (v)

Warranty1 Year

Usage & ApplicationsIndustrial

Carton Box Strapping Machine

Price: 250000 INR/Unit

MOQ1 Unit/Units

ColorGrey And Yellow

TypeCarton Box Strapping Machine

MaterialMild Steel

ComputerizedYes

Automatic GradeSemi-Automatic

Selection ModeAutomatic

Joy Pack India Pvt Ltd

Delhi

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller20 Years

View More

Fully Automatic Strapping Machine (Big Arch Model)

Price Trend : 50000.00 - 150000.00 INR

In-line Automatic Strapping Machines

Price : 195000 INR

Heavy Duty Stretch Wrapping Machine

Price : 225000 INR

Sleeve Wrapping Machine - Automatic Grade: Automatic

Price : 750000 INR

Fully Automatic Strapping Machine - Stainless Steel, Adjustable Dimensions, Sleek Black Color | Fully Automatic Operation, Customizable Weight, Warranty Included

Price: 570000.0 INR/Unit

MOQ1 Unit/Units

ColorBlack

TypeStrapping Machine

MaterialStainless Steel

Automatic GradeAutomatic

Dimension (L*W*H)As per available Millimeter (mm)

Weight (kg)As per available Kilograms (kg)

Apt Tools & Machinery India Private Limited

Coimbatore

Trusted Seller

Trusted Seller Super Seller

Super Seller1 Years

View More

Semi Automatic Pallet Strech Wrapping Machine - Color: Yellow

Price : 550000 INR

Strapping Machine - Automatic Grade: Semi-Automatic

Price : 78000.0 INR

High Speed Automatic Strapping Machine - Color: Black

Price : 610000.0 INR

Automatic Stretch Flim Wrapping Machine - Color: Black

Price : 750000 INR

Fully Automatic Pallet Strapping Machine - Material: Stainless Steel

Price : 2400000 INR

Fully Auto Strapping Machine - High Performance, Rugged Design | Reliable, Durable, Low Maintenance, Innovative Automation

MaterialSteel

Dimensions72X48X60 Inches

Power220V

Weight500Kg

Strapping TypePet

Speed20Spm

View More

Floor Model Strapping Machine - Automatic Grade: Semi-Automatic

Price : 70000 INR

Vertical Strapping Machine - 2.0 sec Strap Cycle Speed, Max Strap Width 19 mm, 105 kg Weight, 250 W Motor | Semi-Automatic, Heat Sealed, HMI Control

Price : 80000 INR

Dbc800 Box Stretch Wrapping Machine Pneumatic Machine - Automatic Grade: Semi-Automatic

Get Best Deal

Box Stretch Wrapping Machine Pneumatic Dbc800 Machine - Automatic Grade: Semi-Automatic

Get Best Deal

Mild Steel M3-6 Combo Strapping With Sealer

Price: 200000 INR/Piece

MOQ1 Number

ColorBlue

TypeSealing Machines

MaterialMild Steel

FeatureHighly Efficient, Less Power Consumable, Heavy Duty Machine, Durable, Rust Proof

Auxiliary Packaging Machine TypeOther

Capacity20 Pcs/min

FAQs Related to Automatic Strapping Machine

MS Semi-Automatic Strapping Machine - Mild Steel, 150x160x100 mm | Strapping Speed 15-20 Cartons/min, 143 kg Weight, 1-Year Warranty

Price: 62000.00 INR/Unit

MOQ1 Piece/Pieces

TypeStrapping Machine

Materialmild steel

Automatic GradeSemi-Automatic

Strapping Speed15-20cartons /min m/m

Dimension (L*W*H)150*160*100 Millimeter (mm)

Weight (kg)143 Kilograms (kg)

Shree Raj International Private Limited

Kolkata

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

View More

Box Strapping Machine - Mild Steel, 900*570*735 mm | Automatic Operation, Uniform Tensioning, 1-Year Warranty, Ideal for Cartons and Containers

Price : 70000.0 INR

Table Top Strapping Machine - Automatic Grade: Automatic

Price : 67900 INR

Semi Automatic 5 HP Box Stretch Wrapping Machine

Price : 360000.00 INR

Packway Fully Automatic Strapping Machine - Capacity: 25 Pcs/Min

Price: 220000 INR/Unit

MOQ1 Unit/Units

ColorBlack & Silver

MaterialCast Iron

Capacity25 Pcs/min

Automatic GradeAutomatic

Control SystemFrequency Speed Control

Strapping Speed26 m/m

Indian Packaging Corporation

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller1 Years

View More

Table Top Strapping Machine - Stainless Steel, 80 kg , Black & Silver | Semi-Automatic, 1.5 m/s Strapping Speed, Frequency Speed Control, 1-Year Warranty

Price : 30000 INR

Semi-Automatic Bottle Shrink Wrapping Machine - Color: White

Price : 360000 INR

Carton Strapping Machine - Stainless Steel, 90 kg | Blue & Black Color, Semi-Automatic, 1.6 m/s Strapping Speed, Frequency Speed Control, 1 Year Warranty

Price : 30000 INR

Indusrial Shrink Wrapping Machine - Automatic Grade: Semi-Automatic

Price : 35000 INR

Heavy Duty Box Strapping Machine - Automatic Grade: Semi-Automatic

Price : 29500 INR

Fully Automatic Strapping Machines - Color: Blue & White

MOQ10 Unit/Units

TypeFully Automatic Strapping Machines

MaterialMild Steel

ComputerizedNo

Automatic GradeAutomatic

ColorBlue & White

Warranty1 Year

Semi-Automatic Strapping Machine - Max Strapping Force 60kg, Dimensions 900x580x750 mm, Strapping Speed 1.5 Seconds per Strap, Ideal for Box and Luggage Strapping

Power220V, 50Hz, 320W

Dimensions900X580X750 Mm

Weight100 Kg

Strap Size6-15 Mm

Strapping Speed1.5 Sec/Strap

Strapping Force60Kg

View More

Horizontal Flow Wrapping Machine - Metal, 800 kg | Automatic Operation, 220V, Warranty Included

Price : 500000 INR

Automatic Shrink Wrapping Machine - MS Material, 200-400 Packets/Hour Capacity | Automatic Grade, 50-60 Hz Frequency, Blue Color, 220-240V Voltage, Warranty Included

Price : 320000.0 INR

Automatic Shrink Wrapping Machine - Stainless Steel, 600 Kg Weight, Blue Color | PLC Control, Heavy Duty, Highly Efficient, Customizable Specifications

Price : 160000.0 INR

Automatic Strapping Machine - Metal/Steel, 1400mm x 600mm x 1540mm , 25-700 Strapping Force, 2.5 Seconds Per Strap, 1-Year Warranty

TypeAutomatic Strapping Machine

MaterialMetal/Steel

CapacitySuitable for various strapping sizes

ComputerizedNo

Automatic GradeAutomatic

Control SystemOther, Manual/Toggle

Shri Vinayak Packaging Machine Private Limited

New Delhi

Trusted Seller

Trusted Seller8 Years

View More

Semi Automatic Strapping Machine Deluxe Model

Get Best Deal

Semi Automatic Strapping Machine Regular

Get Best Deal

Semi Automatic Strapping Machine Feather Touch

Get Best Deal

Fully Automatic Strapping Machine (Online)

Get Best Deal

Semi Automatic Strapping Machine - Mild Steel, 900 x 580 x 750 mm | 1.5 sec Strapping Speed, 450 Newton Strap Force, 1-Year Warranty

Price: 30000 INR/Unit

MOQ1 , Unit/Units

TypeStrapping Machine

MaterialMild Steel

Automatic GradeSemi-Automatic

Dimension (L*W*H)900 x 580 x 750 Millimeter (mm)

Warranty1 Year

Shri Vinayak Packaging Machine Pvt. Ltd.

New Delhi

Trusted Seller

Trusted Seller Premium Seller

Premium Seller5 Years

View More

Pallet Strapping Machine - Mild Steel, 550x700x1300mm , Blue Color, Semi-Automatic, 1 Year Warranty

Price : 35000 INR

Box Strech Wrapping Machine - Automatic Grade: Automatic

Price : 95000 INR

Fully Automatic Strapping Machine - Durable Die Cast Aluminium Alloy, 1420x650x1565 mm Size, 25-700 Strapping Force | Compact Design, Energy Efficient, 1 Year Warranty

Price : 200000.00 INR

Heavy Duty Low Table Strapping Machine - Automatic Grade: Automatic

Price : 52000 INR

Semi-Automatic One Touch And Easy Operation Semi Automatic Grade Strapping Machine

Price: 34000.00 INR/Piece

MOQ1 Piece/Pieces

ColorWhite and Blue

TypeStrapping Machine

Automatic GradeSemi-Automatic

Dimension (L*W*H)910*580*730 Millimeter (mm)

Shri Ram Packaging System

Indore

Trusted Seller

Trusted Seller Premium Seller

Premium Seller7 Years

View More

Semi Automatic Strapping Machine - Metal, 895x565x735 mm | Green, 0.25 HP Motor, 2 Second/Strap, Heat Sealed

Price : 38000 INR

Automatic Shrink Wrapping Machine - 100-180 W Power, Silver Color, Excellent Functionality, Low Power Consumption, Minimum Maintenance

Price : 42000.00 INR

Shrink Wrapping Machine Bs-4525 - Automatic Grade: Semi-Automatic

Price : 58000 INR

Stretch Wrapping Machine Dbc800 - Automatic Grade: Semi-Automatic

Price : 48000.0 INR

Cast Iron Upper Gear Housing For Strapping Machine Usage: Industrial

Price: 2550 INR/Unit

MOQ1 Unit/Units

MaterialGray Cast Iron

UsageIndustrial

Strapera Strapping Technology

Rajkot

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

View More

Carton Strapping Machine - Mild Steel, Blue Color | High Productivity, Variable Strapping Speed, Automatic Feeding and Cutting

Price : 60500 INR

Semi Automatic Box Strapping Machine - Mild Steel Build, Blue Color | Efficient Strapping Solution for Durable Packaging

Price : 35500 INR

Semi-Automatic Industrial Steel Strapping Machine

Price : 35500 INR

Blue 0.25 Kw Semi Automatic Strapping Machine

Price : 68500 INR

Red Fully Automatic Box Strapping Machine With 100-500 Kilograms

Price : 100000 INR

Silver Semi Automatic Strapping Machine Motor

Price : 6500 INR

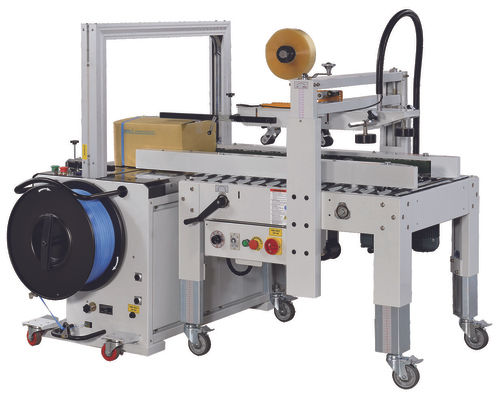

Metal Carton Sealer With Automatic Strapping Machine

Price: 425000.00 INR/Piece

MOQ1 Perch/Perches

TypeStrapping Machine

MaterialMetal

ComputerizedNo

Automatic GradeAutomatic

Shri Vinayak Print Pack

New Delhi

Trusted Seller

Trusted Seller Premium Seller

Premium Seller7 Years

View More

Heavy Duty Low Table Strapping Machines - Metal Build, Semi-Automatic Operation | Ideal for Industrial Applications

Price : 52000 INR

Box Strapping Machine - Metal, Semi-Automatic Operation | Efficient Packaging Solution for Versatile Strapping Needs

Price : 52000 INR

Automatic Strapping Machines - Metal, Automatic Grade | Non-Computerized, Efficient Packaging Solution

Price : 510000.00 INR

Semi Automatic Strapping Machine - Stainless Steel, Green Color, Strap Width 6-15mm, Heat Sealing Method, 1.5 Sec/Strap Speed, Auto Power Off & Adjustable Cooling Time Features

Price: 36000 INR/Unit

MOQ1 Unit/Units

ColorGreen

TypeStrapping Machine

MaterialStainless Steel & MS

Automatic GradeAutomatic

Selection ModeAutomatic

Warranty6 Months

Pack Maker Packaging Solution

Rajkot

Trusted Seller

Trusted Seller Premium Seller

Premium Seller14 Years

View More

Bottle Wrapping Machine - Stainless Steel, White Color | Semi-Automatic, Electric Drive, 120-440 Voltage, 6 Month Warranty

Price : 270000 INR

Shrink Wrapping Machine - Stainless Steel & MS, Automatic Operation | 6-Month Warranty, 120-440 Voltage, White & Orange Finish

Price : 30000 INR

Fully Automatic Strapping Machine - Stainless Steel & MS, White Color, 6 Months Warranty | Automatic Selection Mode

Price : 36000 INR

Automatic Strapping Machine - Stainless Steel, Semi-Automatic Design | Frequency Speed Control, Manual Selection Mode, Warranty Included

Price: 48000.0 INR/Unit

MOQ1 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemFrequency Speed Control

Selection ModeManual

WarrantyYes

Centra Autopac India Private Limited

Coimbatore

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

View More

Semi Automatic Electric Strapping Machine - Cast Iron, Variable Dimensions, Gray and Yellow | 220V, 50Hz, 700W Power, 100 kg Weight, Manual Control

Price : 48000.0 INR

Luggage Wrapping Machine - Metal Construction, Yellow and Black Finish | Automatic Operation, Heavy-Duty for Secure Luggage Protection

Price : 192000 INR

automatic egg tray wrapping machine

Price : 460000.0 INR

Semi Automatic Carton Strapping Machine - Steel Material, 90 kg Weight, Blue Color, 1.5 Seconds Per Strap Speed | Manual Control System, 1 Year Warranty

Price : 64000.0 INR

Automatic Pallet Strapping Machine

Price : 48000.0 INR

Semi-Automatic Semi Automatic Heavy Duty Carton Strapping Machine

Price: 77000 INR/Unit

MOQ1 Unit/Units

TypePackaging Line

MaterialPowder Coated MS

FeatureHighly Efficient, Durable, Other

Auxiliary Packaging Machine TypeOther

Automatic GradeSemi-Automatic

Power500 Watt (w)

View More

Semi-Automatic Semi Automatic Strapping Machine ( Feather Touch )

Price : 37500 INR

Automatic Pallet Stretch Wrapping Machine By Mechsol

Price : 315000 INR

Semi-Automatic Semi Automatic Strapping Machine Economic

Price : 38000 INR

Newspaper Bundling Strapping Machine - Capacity: 200 Kg/Hr

Price: 45000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

TypeStrapping Machine

MaterialStainless Steel

Capacity200 Kg/hr

Dimension (L*W*H)895x565x740 Millimeter (mm)

Weight (kg)50-90 Kilograms (kg)

View More

Industrial Strapping Machine - Capacity: 200 Kg/Hr

Price : 45000 INR

Semi Automatic Strapping Machine - Capacity: 200 Kg/Hr

Price : 38000 INR

SHRI KRISHNA Strapping Machines

Get Best Deal

In Line Automatic Sleeve Wrapping Machine

Price : 390000 INR

Strapping Machines - Color: Blue

Price: 1 INR/Piece

MOQ1 Unit/Units

Usage & ApplicationsIndustrial

ColorBlue

SizeStandard

MaterialPP

Weight100 Kilograms (kg)

UsageIndustrial

K. D. International

Faridabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller14 Years

View More

Semi Automatic Carton Strapping Machinery

Get Best Deal

Pallet Stretch Wrapping Machine - Automatic, 2500x1500x2700 mm, White | Highly Efficient, Durable, Electric Drive, 1 Year Warranty, Rust Proof

Price : 450000 INR

Fully-Automatic Strapping Machine - Color: Blue

Price : 185000.0 INR

Battery Operated Strapping Machine - Semi-Automatic, Width 16-25mm, Thickness 0.5-1.7mm, Black | 14.8V Battery, Electric Drive, 400N-5000N Tension

Price : 130000 INR

Full Automatic Banding Cartoning Strapping Machine

Price: 22500 USD ($)/Unit

MOQ1 Unit/Units

TypeCartoning Strapping Machine

MaterialMild Steel

Automatic GradeAutomatic

Control SystemPLC Control

Selection ModeAutomatic

Dimension (L*W*H)1000*250*800 Millimeter (mm)

Wenzhou Trustar Machinery Technology Co., Ltd.

Ruian

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

View More

Silver Automatic Feeding Wrapping Machine

Get Best Deal

Cartoon Strapping Machine - Automatic Grade: Automatic

Price: 70000.0 INR/Unit

MOQ1 Unit/Units

Typestrapping machine

MaterialMS

ComputerizedNo

Automatic GradeAutomatic

Control SystemHuman Machine Interface

Selection ModeManual

Popular Automatic Strapping Machine

What is an Automatic Strapping Machine? Benefits, Types, Applications, and More

An automatic strapping machine is packaging equipment used in several industries to strap packed containers for further protection. In the strapping process, a steel or plastic strap is applied around a carton or bundle to secure the item. The machine applies tight straps automatically without manual intervention from humans, which saves a lot of time and money. Most commonly, such equipment is found in warehouses, logistics, manufacturing facilities, and more. However, the selection of the right automatic strapping machine is essential for which this article shares in-depth information.

How Does Automatic Strapping Machine Work?

There are multiple steps to learn about to completely understand the workings of this machine:

-

Feeding Straps

The first step is to feed the straps into the machine which it automatically does. With the help of rollers and belts, the machine draws the strap from the roll.

-

Detecting Package

As the packages go through the machine the sensors detect the package to strap it down on their own.

-

Strapping

Based on the design of the machine, the packages are detected and strapped either on top directly or around it. This provides enhanced stability to the packages preventing the chances of material damage.

-

Tightening

Afterward, the motor stretches the strap for more tension and tightens it strongly.

-

Sealing

To secure the package effectively the machine then seals both ends of the strap either by heat or friction seal.

Major Applications of Automatic Strapping Machines in Various Industries

-

Packaging Industry

In this industry, strapping machines are used for various applications including putting straps to the bundles, securing the packaging of containers, and sealing cartons with straps. With this, the products inside these packages are highly secured to be further transported and marketed. Moreover, it also ensures that small bundles are strapped together to form a larger product for easy handling.

-

Logistics and Warehousing

In warehousing and logistics where there is a constant need for material handling tasks, the strapping machines are used for securing multiple packages together for easy storing and handling. Moreover, when the packages are loaded or unloaded, they are sealed with straps so that they stay intact and damage remains negligible.

-

Food & Beverage

These machines are used in the food & beverage industry for various applications including securing pallets of bottled and canned beverages, strapping the cartons or boxes of snacks or dairy products for transit, and sealing the sacks of bulk goods or materials including salt, sugar, flour, etc.

-

Manufacturing Plants

Various types of manufacturing plants use strapping machines to secure their products. These include industries like electronics, where the packaging of gadgets requires strapping for protection. And others like the automotive and textile industries where the products require bundling in bulk for transportation.

-

Construction Site

At construction sites, there are a variety of items or materials that require strapping to stabilize and easy transport like wooden planks or pallets, metal rods or pipes, and bricks or tiles. These items become easy to handle after they have been secured with strong straps. The workers can just use any type of material handling equipment to lift them at once and move to another place.

-

Pharma and Cosmetics

In the pharma industry, strapping machines are used for securing cartons of medicines with strong straps that make them easy to store and transport. The same goes for the cosmetics industry, these machines help strap the bundles of cosmetic products so that they become easy to handle. Even though the process is not very significant, it is effective enough to make material handling a lot easier.

-

Retail and E-commerce

In retail stores and the e-commerce industry, strapping machines are used for binding the packaging of the products carefully for efficient handling, storing, and preventing damage. Retail stores even use straps manuals to secure the packages carefully and ecommerce spaces handle the hundreds of packages daily which becomes much easier with strapping machines.

-

Agriculture

In this industry, there are various types of goods and items that require strapping before storing and transportation like fertilizers, crates of goods & vegetables, and sacks of seeds & animal feed. They can use manual or automatic strapping machines based on the scale of work and operational budget.

Benefits of Automatic Strapping Machine

-

Consistent Quality

Automatic machines use bundles of straps and constantly apply force to tighten their grip securing the packages. It provides the same quality from the first package to the last offering consistent quality. This way, the strapped packages become easy to protect, store, and transport.

-

Enhanced Productivity

Industries like manufacturing, warehousing, logistics, etc. require strapping hundreds of packages daily, and doing it manually costs them a lot of time and resources. Automatic machines help them to enhance overall productivity with performance and faster operations. These machines not only secure the packages but the same of them have advanced features like labeling to print detailed info on the products.

-

Cost Saving

Automatic strapping machines are highly cost-saving as they reduce or eliminate the need for manual strapping which requires increased labor costs and high use of resources. With quick operations and saved time, the workers can focus on other essential tasks to contribute to a higher production rate.

-

Adjustable Tension

After the strap has been applied to the package, the machine puts tension on the ends of the strap to secure it. The intensity of the tension can be adjusted by the machine as per the requirement, size, or structure of the package. Each package contains different types of products and workers can adjust the required tension for them quickly with the user-friendly interface of the machine.

-

Safety Enhancements

Advanced strapping machines come with the most effective safety features to prevent workplace incidents. These safety features include an emergency stop button, side guards, warning sensors, etc. that allow the workers to be safe in any working condition. They can show productivity without worrying about their safety at the workplace.

-

Reduced Waste

Automatic machines handle the complete process from filling material to sealing, with high precision and accuracy. This is why they use the materials very efficiently, reducing the wastage of resources. The companies can save a lot on operation costs with the help of these machines.

-

Versatility

Strapping machines are highly versatile as they support every type of packaging including boxes, containers, cartons, canned products, bottle or fruit crates, etc. They can strap any kind of packaged goods or item with accuracy, and help to prevent damage during storage or transportation.

How to Choose the Right Automatic Strapping Machine for Yourself?

There are multiple factors you must consider before you choose the strapping machine for yourself:

-

Production Rate

You must identify the product rate you require to fulfill the orders of your clients and meet the deadlines. Compare the stats with the machine's maximum capacity to strap the packages and you will get your answer. For better results just hire the machine that has more product capacity than you require for smooth operations. Generally, you can decide between manual, automatic, and semi-automatic machines. For small-scale production, a manual or semi-automatic will be enough. However, for large-scale operations, you require a fully automatic strapping machine.

-

Package Size and Volume

Check what package size the strapping machine supports over your requirement. With this, you will be able to know whether the machine can strap down large-size packages, small packages, or both. Knowing this, will clear your confusion about the machine that you’re investing in. will support the type of packages or containers that you want to strap. Wrong decisions may result in unnecessary expenses.

-

Types of Strap

The straps are also made from different types of materials including plastic for small packages and steel for high strength to secure large packages. You must know before investing in the new machine what type of straps it supports. In some cases, you still want to have a machine that supports both, because your packaging operations may require both small and large objects.

-

Types of Seal

Another important factor is the type of seal your new packaging machine can apply to the packages. There are two types of strapping seals including bottom seal and side seal. The best scenario will be if your machine supports both the bottom seal, which is essential for large-size or bulky packages, and the side seal, which is commonly applied on irregular-sized packages.

-

Tension Force

Strapping machines apply tension once the strap is applied to the package to tighten the grip and secure the package. Before choosing the strapping machine you must know if the machine has an adjustable tension feature or not. This is because the varying shapes and sizes of the packages require machines to apply forces of a wider scale. Where bulk packages require high strength, the smaller packages require a light grip for better handling.

-

Floor Space

You will need to assess the available space in your facility over the space required by the machine to be installed. Installing the machine will require a short training after which an operator can easily guide the workers. You should choose the installation site where the machine can function by easily integrating with the existing packing system. For better convenience, you must choose a place where there’s still room left for maintenance and repairs around the machine.

-

Easy to Use

Automatic strapping machines come with highly advanced features making the packaging operations smooth and seamless. Although it sounds a little bit complex, the machine has a user-friendly interface and one-click functions that make it very easy to use. Any operator can become eligible to use it with a short training session. All the controls are designed to be very ergonomic so the operators don't get tired even after working long hours.

-

Low Maintenance

These types of heavy-duty machines are designed using the best quality raw materials for durability and long lifespan. They don't get affected much by harsh working environments and long hours. Due to these reasons, the strapping machines require frequent maintenance, only the regular sessions are enough, and that too at a very low cost. However, you must know about routine procedures and their processes to rectify the problems yourself.

-

Integration Level

Another important factor to consider is whether the machine is compatible with your existing packaging system or not. Commonly the machines are designed to be compatible with your existing packing setup so that the companies don’t have to make major investments to source new. Existing systems can be conveyors, material feeders, etc.

-

Customization

The levels of customization your machine supports depend on the manufacturer's ability to craft excellent machinery. You must select the best manufacturer to source your strapping machine which supports customizations in case you need to work with different types of packages or products to pack, seal, and transport. However, if your equipment doesn’t have room for customization to upgrade, you will have to make significant investments to source new gear.

Automatic Strapping Machine Price List

This Data was Last Updated on 2025-12-20

Automatic Strapping Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Shri Vinayak Packaging Machine Pvt. Ltd. New Delhi, India | 21 Years |

Joy Pack India Pvt Ltd Delhi, India | 20 Years |

Durapak Chennai, India | 18 Years |

Join Pack Machines (pvt.) Ltd. Delhi, India | 18 Years |

Shri Krishna Packaging Consultants Pvt. Ltd Delhi, India | 17 Years |

Vijay Enterprise Kolkata, India | 15 Years |

Pack Maker Packaging Solution Rajkot, India | 14 Years |

K. D. International Faridabad, India | 14 Years |

Smart Packaging System Indore, India | 10 Years |

Shri Vinayak Packaging Machine Private Limited New Delhi, India | 8 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Panacea - Natural Products Expo India 2026

Fri, 06 Mar, 2026 - Sun, 08 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories