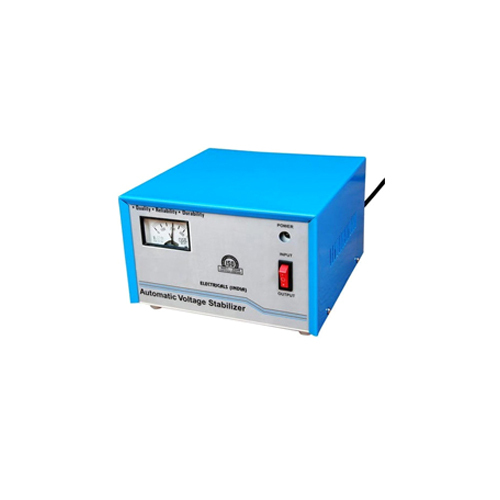

Automatic Voltage Stabilizers - High Grade Raw Materials, 3-phase Output, 400v ± 1% | High Efficiency, Low Maintenance, Easy Usage

Price:

Get Latest Price

In Stock

Product Specifications

| Input Voltage | 300-460V |

| Output Voltage | 400V |

| Efficiency | 98.5-99.5% |

| Cooling | Oil cooled |

| Mounting | Wheels |

| Material | Steel |

| Dimensions | Variable |

| Features | Voltage regulation, Overload protection, High efficiency, Easy installation, Low maintenance, Durable design, Reliable performance, Cost effective |

Product Overview

Key Features

Automatic Voltage Stabilizers

Clients can avail from us a wide range of Automatic Voltage Stabilizers at affordable costs. These are made up of high grade raw materials and cutting edge technologies to ensure international standards of quality. Available at affordable rates, our Automatic Voltage Stabilizers are preferred for their high efficiency, optimum performance, easy usage and low maintenance.

Additional Details:

Voltage fluctuation is a common phenomenon in every part of the country. The industrial units running round the clock, usually face the problem of low and high voltage. 90% of industrial load is of motors. Electric motors draw considerably high current at low & high voltage. This higher current affects the electrical motors (particularly smaller capacity motors upto 7.5 H.P.) in three ways.

These higher losses of electric motors also increase the losses of cables, switches, transformers and other associated equipments.

For smooth continuous operation of motors, overload relays are usually set at 20% higher setting.

Adverse Effects Of Single Phasing

- The line current increases by 1.5 times.

- If the relay setting is at 15-20% higher than actual operating current then the relay will take 4-6 minutes to trip.

- The motor (particularly smaller capacity motors upto 7.5 H.P.) cannot withstand this high current for such a long time and in most of the cases it burns out before the relay trips.

- Heavy short circuit current flows through the relays, contactors, cables etc.

- Under this condition when the relay, contactor trips, they produce sparks and some times bursts..

- This further damages the switchgear and in some of the cases may cause fire also.

| 340V-400V | 400V-440V | 340-400v | 400V-460V | 420V-470V | 400V-450V |

| 09.00 AM-12.00 Noon | 12.00 Noon-14.00 PM Lunch Hours | 14.00 PM - 18.00 PM | 18.00 PM -22.00 PM Peak Hours Restriction | 22.00PM - 05.00 AM | 05.00AM - 09.00 AM |

Specifications

Sushil's servo stabilizers are available in a wide range and various models. The standard Three phase models are suitable for balanced & unbalanced supply and loads. The standard models confirm to the following specification:

- Input Voltage : 360-460 V, 340-460 V, 320-460 V & 300-460 V

- Efficiency (approx.) : 99.5% 99% 98.7% 98.5%

- Output Voltage : 400 V + / - 1%, 3-Phase, 50 Hz

- Cooling : Naturally Oil Cooled

- Type : Indoor

- Temp. Rise (max.) : 30 deg C above ambient

- Mounting : On Uni-directional Wheels

- Correction Rate : 6-8 V/Sec. (Upto 500 KVA) and 3-4 V/Sec.

- Wave form distortion : (Above 500 KVA)

- Duty Cycle : Virtually Nil

100% Continuous

Who Needs A Stabilizer

The industrial units having abnormally higher failure rate of Electrical Equipments such as bulbs, tubes, chokes, starter, contactor coils & motors (particularly smaller capacity motors upto 7.5 H.P.) Etc. Should verify that it may be due to HIGHER voltage. You may note down Hourly readings of voltage variation for few days. If you find that input voltage is above 230 volts single phase/400 volts Three phase even for few hours a day, then you definitely require a stabilizer

How To Access Higher Losses & Low Power Factor In Industrial Units Without Installing Stabilizer

- Note down hourly readings of current and voltage of one motor operating at constant load for 2-3 days. From the different readings you will observe that the current drawn by the motor is minimum at 390/400 volts as compared to the current drawn at other voltages. This means that power consumed by the motor is minimum at 390/400 volts.

- Also note down hourly readings of voltage and K.W. from your Electronic Energy Meter for 2-3 days. From the readings you will observe that K.W. is minimum at 390/400 volts in most of the readings as compared to the higher voltage.

- Reduction in Breakdown of Electrical Equipments

- Energy Saving

- Improvement in Power Factor

- Reduction in MDI

- Uniform Quality of End Product

- 80% Depreciation as per Income Tax Act

| The table below gives approximate quantitative advantages of Automatic Voltage Controller at various fluctuation levels. | ||||

| Input Voltage Variation | % reduction In Breakdown of Electrical equipments | Appx. Power Saving Possible | ||

| Motor Load Below 10 hp | Lighting Load | Motor Load Below 10 hp | Lighting Load | |

| 380-400 Volts | Nil | Nil | Nil | Nil & servo stabilizer is not required |

| 400 - 420 volts | 5% | 10% | 3% | 5% |

| 420 - 440 volts | 10% | 20% | 5% | 10% |

| 440 - 460 volts | 40% | 40% | 7% | 20% |

| 460 - 480 volts | 60% | 60% | 10% | 30% |

Benefits Of Installing Automatic Voltage Controller On Lighting Load

By maintaining 365 / 210 volts - three / single phase output through Automatic Voltage Controller for Lighting Load, there will be definite saving in power bill & reduction in failure rate of lighting equipments. Higher the input voltage - more will be the savings. The overall effect on the reduction in brightness of the lamp at 210 volts will be negligible.

Payback Period

Owing to its high efficiency and associated benefits, the payback period for the cost of Sushils Servo Voltage Stabilizer is from 6-12 months depending upon the input voltage variation and number of working hours of the plant. The HIGHER the input voltage the SHORTER will be the payback period.

DESCRIPTION OF Sushil's MAKE AUTOMATIC VOLTAGE CONTROLLER

Sushil s Servo Stabilizer primarily consists of the following:

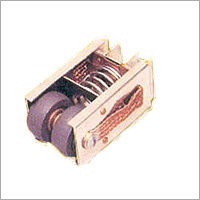

Carbon roller assembly : Shusil electrical

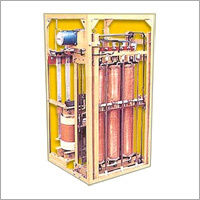

Close view of regulator : Shusil electrical

- Linear Type Plus/Minus type Vertical Rolling Contact type Regulator.

- Double Wound Buck/Boost Transformer.

- Electronic Control Circuit and meter panel.

The regulator and buck boost transformer are oil cooled, housed in same or separate steel tanks. Radiators, if necessary are provided for effective cooling. Their core is built from grain oriented silicon steel Lamination which keep losses to the minimum and they are wound with electrolytic grade copper to minimize the losses, vacuum impregnated and oven dried as per IS.

Though stabilizers are useful for any kind of application, these are most suitable for 24 hour continuous process plants where breakdowns due to fluctuation results in heavy financial losses. These include :

- Cement Plants

- Flour Mills

- Engineering Units

- Pharmaceutical Units

- Cold storages

- Rolling Plants

- Textile Mills

- Paper Mills

- Tube Mills

- Rice Sheller's

- Rubber Industries

- Tea Estates

- Food Processing Units.

- Oil and Vanaspati Plants.

- Footwear and Leather Units

- Distilleries & Beverages

- Hospitals

- Nursing Homes

- Clubs

- Hotels

- High Rise Buildings

Company Details

Focusing on a customer-centric approach, SUSHIL ELECTRICALS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Voltage Stabilizers in bulk from SUSHIL ELECTRICALS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Solapur, Maharashtra

Proprietor

Mr. Sushil Kumar Shukla

Address

no. 56, Nehru Nagar, Bijapur Road, Solapur, Maharashtra, 413005, India

automatic voltage stabilizer in Solapur

Report incorrect details