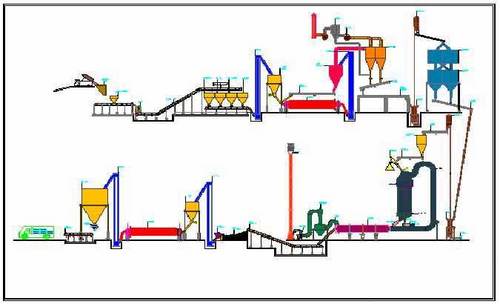

Ball Mill Synthetic Gypsum Plant

Price:

Get Latest Price

Product Overview

Key Features

Use : As a bounding compound.

Raw Materials : limestone, Sulphuric acid

CaCO3+ H2SO4 = CaSO4+H2O

Different form of synthetic or byproduct gypsum are now available for use and are being produced at economical rates which help the gypsum producers. In the business of making cement, gypsum costs usually very economical. Synthetic gypsum reduce costs as well as provide other manufacturing, environmental, and political benefits.

The few sources of synthetic gypsum are power utilities and acid neutralization. Many electric power utilities use high-sulfur bituminous coal as their source of fuel and in case of acid neutralization the chemical gypsum produced is of high quality, but it also is fine and wet, making it difficult handle.

Natural gypsum: CaSO4. 2H2O

Taking the example of synthetic gypsum manufacturing by power plant

As the power plant has the excess SO2 produced at the plant, these gases are called as Flue gases which are exposed to slurry of hydrated lime.

This lead s to the formation of calcium sulphite (CaSO3. A H2O)

This calcium sulphite is then oxidised to form the required gypsum. Of the formula of CaSo4.2H2O

The most popular source used is lime or limestone. In this process, when the slurry is precipitated, it results in a byproduct known as Flue Gas Desulfurization (FGD) material, or synthetic gypsum.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

55

Establishment

2003

Working Days

Monday To Sunday

GST NO

08AAECM6457C1ZH

Certification

ISO 9001:2008

Related Products

Seller Details

GST - 08AAECM6457C1ZH

Bhiwadi, Rajasthan

Director

Mr Praveen Sharma

Members since

18 Years

Address

G-1-1428, RIICO Industrial Area, Phase V, Bhiwadi, Rampur Mundana, Bhiwadi, Rajasthan, 301019, India

Plant & Machinery in Bhiwadi

Report incorrect details