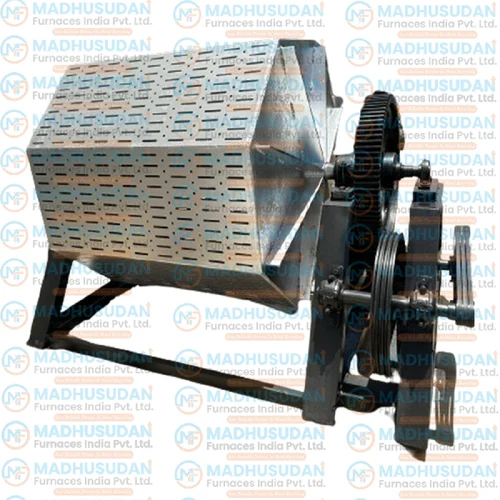

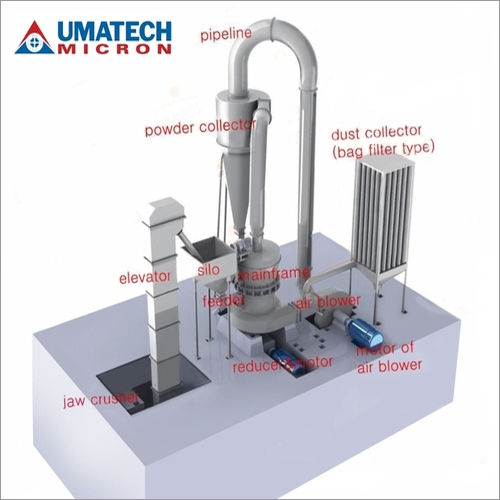

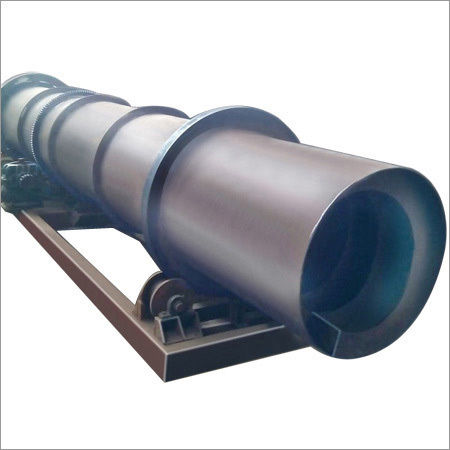

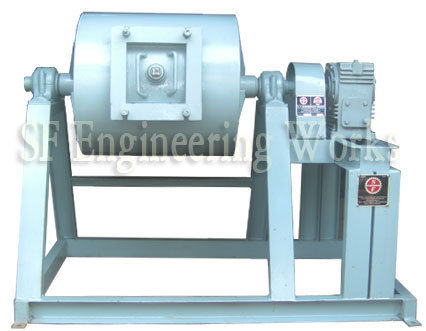

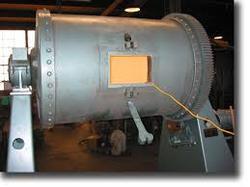

Normal 0 false false false EN-US X-NONE X-NONE /* Style Definitions */ table.MsoNormalTable {mso-style-name:"Table Normal"; mso-tstyle-rowband-size:0; mso-tstyle-colband-size:0; mso-style-noshow:yes; mso-style-priority:99; mso-style-qformat:yes; mso-style-parent:""; mso-padding-alt:0in 5.4pt 0in 5.4pt; mso-para-margin-top:0in; mso-para-margin-right:0in; mso-para-margin-bottom:10.0pt; mso-para-margin-left:0in; line-height:115%; mso-pagination:widow-orphan; font-size:11.0pt; font-family:"Calibri","sans-serif"; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-fareast-font-family:"Times New Roman"; mso-fareast-theme-font:minor-fareast; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin;} We are offering a commendable assortment of Ball Mills that is manufactured by utilizing fine quality materials and advance technology. Available in various specifications, our range is suitable for grinding or mixing various materials like ores, chemicals, ceramic raw materials and paints. These Grinding Ball Mills are rotate around a horizontal axis and grinding is taking place with the heavy balls filled with material. Features: Impeccable efficiencyEasy to use Feeding arrangement with hoppersFurther Details A ball mill, a type of grinder machine, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, grinding is taking place with the heavy balls filled with material to be ground in the ball mill. There are two types of Ball Mills we Manufacture;1. Continuous Type: This type of ball mill provides continuous production in terms of kgs or tons per hour basis. At one end material is fed at controlled feeding rate while at the exit end material is sucked by air attaching pneumatic system or comes out by flotation. It is often provided in complete closed circuit where under sized material is thrown back to feeding end after classifying the particle size through efficient dynamic type classifier.Ball Mill Shell with suitable liners such as High Alumina, Hyper steel, High Manganese, ceramic liners etc.Grinding medium, balls, of various sizes in diameter made of High Alumina, High Manganese, natural pebbles, hyper steel etc.Continuous Ball Mill System includes blower, dust collector, cyclone, classifier, and necessary duct line.Feeding arrangement with hoppers.Application;- Quartz Manganese Ore Phosphate Rock Various HerbsId your material not Lime Stone Calcined Bauxite Coal in the list , please Feldspar Calcite Pet Coke contact us. Iron Ore Dolomite Calcite 2. Batch Type: Material is being charged into ball mill once and the lid of the mill get closed. The mill is being rotated at certain speed and time as long as desired particle size achieved. Once the material is ground, the lid gets opened and the material is being discharged manually or gravitationally.This mill is best suitable for wet grinding operation such as in ceramic and paint industries. or where output is required in low quantity.