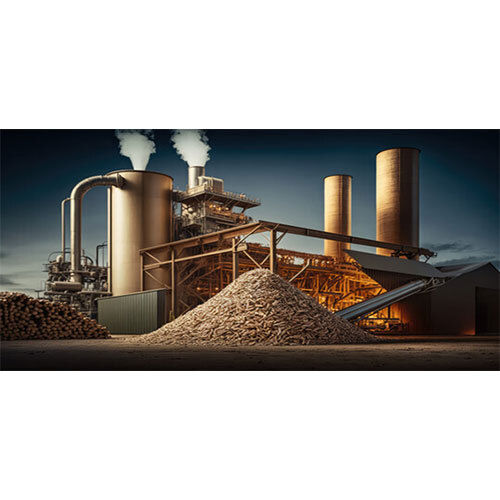

Biomass Burning Wood Pellet Production Line

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Nearly all forestry and agro-waste material can be made into wood pellets by our ring die wood pellet mill, such as: Wood Chips, Shaving, Sawdust, Groundnut-shell, Sugarcane, Caster Shells/Stalk, Coffee Husk, Paddy Straw, Sunflower Stalk, Cotton Stalks, Mustard Stalk, Jute Waste, Bamboo Dust, Tea Waste, Wheat Straw, Palm husk, Soybeans Husk, Coir Pitch Barks/Straws, Rice Husks etc. The final pellets can be used for industrial boilers and large power plants as well as home heating.

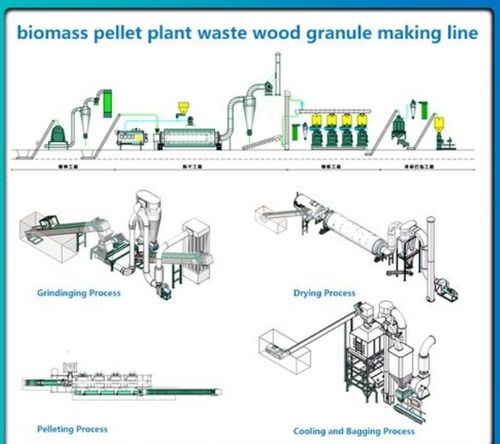

The description of bioamss wood pellet production line.

We can provide different kind of complete biomass pellet production line. The biomass pellet production line suitable for press the different kind of wood wast, wood scrap, wood shaving and other biomass materials such as rice husk, corn cob, straw , palm fiber and other agricultural waste into good quality biomass fuel pellets.

Biomass wood pellet production line including the follow sections.

wood sawdust making section, for cutting the log wood or wood branches into sawdust directly

the drying section, for drying the wet materials into good moisture content about 15%

The pellet making section, this is the mainly part of this wood pellet production line, good for press 100% sawdust powder or any other kind of biomass materials into good quality pellets.

The cooling and screening section, for cooling the pellets and separate the dust and broken pellets,made the output pellets is good for storage.

The packing section, for packing the final produces into bags, normally can be 15-50kg/bags.

the control section, for different control cabinet and control system to control all the equipment, with overload protection system and also with motor protection system inside the control cabinet.

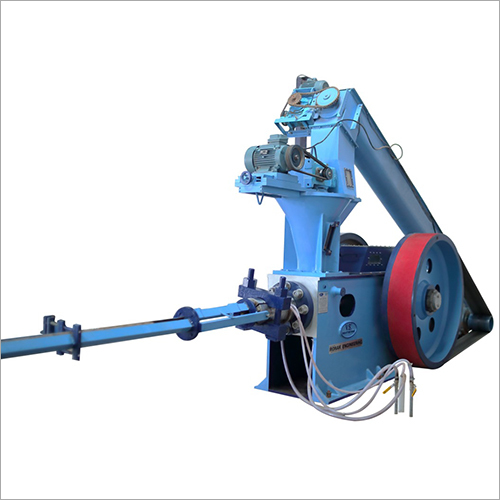

Main Machine Wood Pelletizer:-

1. It is widely used for pellet of light substance, such as wood chips, sawdust, straw, pasture, chrysanthemum, palm leaf and so on;

2. The feeder's especial structure makes materials conveyed evenly, it is specially designed for pellet of light substance with the density of 0.3-0.6g/ cm3;

3. Feeder, conditioner and chute are made of stainless steel with long service life;

4. It is with magnet and over load protection system, which can protect machine well during production;

5. Feeder is with a variable speed controlled to meet different outputs requirements;

6. It makes gear directly-connecting as the driver, and is with quick-release die fixed by clamps, which can increase the output 15% more than the same type machine with belt-convey;

7. The bearing and oil seal in the main drive are imported from Japan to ensure highly-efficient, stability, credibility;

8. The alloy steel die is with international advanced equipment and technics, and has long service life, slippery pellet and high quality.

Company Details

Focusing on a customer-centric approach, Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Plant & Machinery in bulk from Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Establishment

2003

Related Products

Explore Related Categories

Seller Details

Changzhou, Jiangsu

General Manager

Mr. Zhi Liang Chen

Address

#6 Chenyang Road, Jiangsu Zhongguancun Science And Technology Industrial Park, Liyang, Changzhou, Jiangsu, 213300, China

biomass plant in Changzhou

Report incorrect details