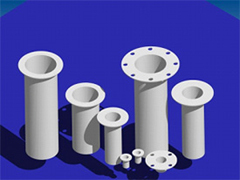

Nozzles

(5906 products)PTFE Nozzle - Pure PTFE and Filled Grades (Bronze, Carbon, Glass) | Chemical Resistance, Reduced Wear Rates, Stability, Weather Resistance

Product DescriptionWe design and deliver the best quality range of PTFE Components to our valued customers. PTFE Components are fabricated by highly creative work force that has got vast experience in this domain.\015\012\015\012We bring PTFE Nozzles as per Client Drawing or Specifications in Pure PTFE and other Fill

Ptfe Nozzle Liners Density: 2.2 ~ 2.4 Gram Per Cubic Meter (G/M3)

MOQ1 Piece/Pieces

MaterialPTFE

Density2.2 ~ 2.4 Gram per cubic meter (g/m3)

Thickness6-660 Millimeter (mm)

Melting Point600 K, 327 Degree C

Size12-400 MM

Width1-2 Inch (in)

Dhwani Polymer India Private Limited

Ahmedabad

Plastic Abrasive Blasting Nozzle Holders

Price Trend: 300.00 - 600.00 INR/Piece

MOQ2 , Piece/Pieces

Product TypeBlasting Equipment

MaterialPlastic, Aluminum, Brass

Plastic TypePVC

UsageSand / Abrasive Blasting

Size1, 2, 3, 4

Weight100 - 150 Grams (g)

Pressure Gauges - Material: Brass

Price: 1000 INR/Piece

MOQ10 Piece/Pieces

Product TypePressure Gauges

MaterialBrass

Metals TypeSteel, Copper, Other

UsageIndustrial

SizeStandard

Finger Multi Jet Nozzles - Material: Brass

Price: 5000 INR/Unit

MOQ5 Unit/Units

Product TypeFinger Multi Jet Nozzles

MaterialBrass

Metals TypeStainless Steel

UsageFor Indore and Outdoor Decoration

Size3.2-3.8 mm

Weight1350 Grams (g)

SWATI BRANCH PIPE NOZZLES

Price: 750 INR/Piece

MOQ1 , Unit/Units

Supply Ability1000 Per Week

Delivery Time1 Week

Stainless Steel Ss Flow Nozzle

Price: 5000 INR/Piece

MOQ1 Piece/Pieces

Product TypeFlow Nozzle

MaterialStainless Steel

Metals TypeSteel

UsageIndustrial Application For High Pressure, Temperature Steam Flow

Ufb Dual Nozzle - Material: Metal

MOQ1 Piece/Pieces

Surface TreatmentPolished

Product TypeUFB Dual Nozzle

MaterialMetal

Metals TypeStainless Steel, Steel

UsageIndustrial

SizeUFB 20A (3/4")

Industrial Eye Ball Nozzle

Payment TermsDelivery Point (DP), Days after Acceptance (DA), Cheque

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Automatic Shut Off Fuel Nozzle

Product DescriptionWe are a very enormous name of the industry for delivering a wide array of Fuel Nozzle to our highly valued clients. These are manufacture by utilizing supreme quality material and innovative technology. Our products are largely used in various sectors. These are attainable at market feasible prices

Abs Mising Special Nozzle Adapter For Flex 310 M 2K

Price: 529 INR/Piece

MOQ1 Piece/Pieces

Product TypeMising Special Nozzle Adapter

MaterialABS

Plastic TypeABS

UsageIndustrial

Lakshmi Electro Controls & Automation

Bengaluru

Misting Nozzle For Sanitizer

Price Trend: 150 - 350 INR/Piece

MOQ1 Piece/Pieces

Supply Ability100 Per Day

Delivery Time1 Days

Jain Pipe Traders Private Limited

Gurugram

Polypropylene Nozzles - Plastic Type: Pp

Price: 650 INR/Piece

MOQ100 , Piece/Pieces

Product TypeNozzles

MaterialPolypropylene

Plastic TypePP

UsageFor Industrial Use

Size4-6 Inch

Industrial Boiler Nozzle - Premium Quality Materials, Rugged Design , Hassle-Free Performance

Product DescriptionBacked by a team of diligent experts, we have been able to manufacture, export and supply a wide range of Industrial Boiler Nozzle in Faridabad, Haryana, India. Our provided nozzles are extremely desired by our patrons for their hassle free performance and rugged construction. The offered boiler noz

Metal Brass Misting Nozzle

Price: 100 INR/Unit

MOQ10 Unit/Units

Product TypeMisting Nozzle

MaterialMetal

Metals TypeAluminum Alloy

UsageIndustrial

Size0.1-0.3 mm

Stainless Steel Spray Nozzle - Material: Metal

Price: 280 INR/Piece

MOQ100 Piece/Pieces

Product Typespraynozzle

Materialmetal

Metals TypeSteel

Usageindustrial

Sizedifferentavailable

Boiler Mixing Nozzle

MOQ1 Unit/Units

Supply Ability6ton Per Day

Delivery Time1week to 8 week Week

Tough Casting Private Limited

Kolhapur

Trusted Seller

Trusted Seller16 Years

Sewer Cleaning Nozzle

Price: 2500 INR/Unit

MOQ2 , Piece/Pieces

Supply Ability10 Per Day

Delivery Time10 Days

Spray Nozzles General Medicines

Product Description\015\012 \015\012 \015\012 Normal \015\012 0 \015\012 \015\012 \015\012 \015\012 \015\012 false

Acmefil Engineering Systems Pvt. Ltd.

Ahmedabad

P80 Plasma Cutting Nozzle - Material: Stainless Steel

Price: 120 INR/Unit

MOQ100 Unit/Units

Product TypeNozzle

MaterialStainless Steel

Metals TypeStainless Steel

UsageIndustrial

SizeDifferent Size

Stainless Steel 1.2 Inch Stainleess Rotary Spray Ball Sanitary Female Thread Cip Tank Cleaning Nozzle

Price: 2120 INR/Piece

MOQ20 Piece/Pieces

Product TypeTank Cleaning Nozzle

MaterialStainless Steel

Metals TypeStainless Steel

Plastic TypePP

Size1.2 Inch

Weight10 Grams (g)

Metal W2 Fluidics Nozzles

Price: 16000 INR/Unit

MOQ1 Unit/Units

Product TypeW2 Fluidics Nozzles

MaterialMetal

UsageIndustrial

SizeDifferent Available

Oxygen Fuel Nozzle - Material: Steel

MOQ1 Piece/Pieces

Surface TreatmentPolished

Product TypeHeating Nozzle

MaterialSteel

Metals TypeSteel

UsageIndustrial

Size3-100mm

Industrial Pumps & Motors Agencies

Kolkata

Super Seller

Super Seller3 Years

Edm Mask Copper Nozzle Size: Customized

Price: 600 INR/Piece

MOQ100 Piece/Pieces

Product TypeEDM Mask Copper Nozzle

MaterialCopper

Metals TypeCopper

UsageIndustrial

SizeCustomized

Flat Spray Nozzles - Material: Stainless Steel

Price: 150 INR/Unit

MOQ100 Unit/Units

Thread size1/4 inch

Pressure6 bar Bar

Surface TreatmentPolished

MaterialStainless Steel

UsageIndustrial

Size1/4"

Hi-tech Power Systems

Bhawanigarh

Premium Seller

Premium Seller1 Years

Plastic Round Misting Nozzles

Price: 54 INR/Carton

MOQ500 Piece/Pieces

Product DescriptionPlastic Round Misting Nozzles

Burner Nozzles - High-Temperature Resistant Alloy, Precision-Machined Design for Enhanced Efficiency

Price: /Piece

MOQ100-200 Piece/Pieces

Supply Ability100 Per Day

Delivery Time1 Week

Flamco Combustions (p) Ltd.

New Delhi

Trusted Seller

Trusted Seller16 Years

Latest From Nozzles

Ready To Ship Nozzles

Nozzle: Introduction

A Nozzle creates high-pressure, high-temperature steam, which is then used to power a nozzle turbine, which turns the shaft. A nozzle is a variable-cross-sectional tube through which the thermal energy of steam is transferred to mechanical motion.

The primary purpose of a nozzle is to create a high-velocity steam jet for use in powering steam turbines. It is the nozzles that cause the high-pressure, high-temperature steam to expand before it is released. Blades on a rotating wheel are hit by the high-velocity steam emitted by nozzles.

When a fluid stream passes between two blades, some of its momentum is lost, and the wheel must compensate by producing torque as it spins. The blades spin because the steam imparts an impulse because to the change in momentum and because expands and accelerates in relation to the blades. That's right; they double as nozzles too.

To transform the thermal energy of steam into mechanical energy, a nozzle is a duct or tunnel with a continuously changing cross-sectional area. This energy conversion is accomplished with minimal waste thanks to the nozzle's carefully crafted shape.

Types of Nozzle

1. Pintaux nozzle

This particular variety of Pintle nozzle is distinguished by the presence of an auxiliary hole that has been bored into the body of the nozzle. A small amount of fuel is injected through this extra hole in the streamwise direction just before the major injection, a process known as pilot injection.

At low speeds, the needle valve doesn't really fully lift, therefore most gasoline is injected through the secondary opening. Better performance when beginning from cold is the primary benefit offered by this nozzle.

This nozzle's injection characteristics are inferior to those of the multihole nozzle, which is one of the key drawbacks of using this nozzle.

2. The Multi hole nozzle

This particular nozzle has a number of holes that have been drilled into the very tip of the nozzle. The number of holes can range anywhere from four to eighteen, and their diameter can be anywhere from thirty-five to two hundred micrometres.

The angle of the hole might range anywhere from 20 degrees to higher. High injection pressure on the order of 18 MPa is required for these Nozzles to function properly.

Their strength rests in the fact that they are able to effectively distribute the fuel despite the fact that open combustion chambers have less air movement accessible to them.

3. The single hole nozzle

This particular kind of nozzle has a single hole in the middle of the body, and the nozzle valve covers it up so that it cannot be used. In most cases, the diameter of the hole is on the order of 0.2 millimetres.

The injection pressure ranges anywhere between 8 and 10 MPa, and the spray cone angle is somewhere about 15 degrees. One of the most significant drawbacks of this nozzle is the fact that it has a propensity to drible.

In addition, the spray angle is much too shallow for effective mixing to be achieved without significantly increased velocities.

4. The pintle nozzle

When it comes to this particular style of nozzle, the stem of the Nozzles valve is extended to from a pin or pintle that sticks out of the mouth of the nozzle. The Pintle can have a size and shape that is tailored to the user's specifications at their request.

It operates at modest injection pressures of 8-10 MPa, providing a spray that can be used. In most cases, the spray cone angle is set at 60 degrees. The ability of this nozzle to prevent dribbling and weak injection is the primary benefit of using it. It stops carbon from depositing on the hole in the nozzle.

5. Convergent nozzle

Figure depicts a typical example of a convergent nozzle. The cross-sectional area of a convergent nozzle continuously shrinks from the point where it enters the nozzle to the point where it exits the nozzle. When the backpressure is either equal to or larger than the critical pressure ratio, it is employed. This is the case when it is used.

6. Convergent-Divergent Nozzle

In this scenario, the cross-sectional area initially drops from the point where it enters to where it has its throat, and then it increases from the point where it has its throat to where it exits.It is a common component in a diverse range of steam turbine designs.

7. Divergent nozzle

From its entrance until its exit, the diverging nozzle exhibits a consistent rise in the cross-sectional area that it possesses. In situations where the back pressure is lower than the critical pressure ratio, it is utilised as a solution.

Why is a Nozzle Important?

Have you ever pondered the reason behind the limited performance of your turbine bypass system? On a routine basis, the spraywater nozzles on your turbine bypass valves or your desuperheaters should be inspected and put through their paces of testing.

i. Installation is quick and uncomplicated, and it is less expensive than using a venturi metre.

ii. It takes up very little space.

iii. possesses a significant discharge coefficient.

iv. They could provide an incorrect or insufficient amount of cooling spray.

v. Result in an excessive amount of water spray entering the steam line.

vi. When compared to the vanturimeter, the physical length is significantly less.

What are the Application of Nozzle in Industry?

The applications of Nozzles are:

1. Cleaning

There are nozzles designed specifically for cleaning tasks. You can get sprays from them to clean your machinery or your goods. Synergies Group provides nozzle valve systems like the VarioSpray.

2. Odor control

During the processing of chemicals and foods as well as during industrial applications, a pungent odour is frequently created. Odors can be caused by gases or particles that are carried through the air.

The odorous particles can be neutralized by using a fine spray either as interact with or absorb them. This will allow for the elimination of the odour. You have the option of spraying the area in question with a variety of odor-neutralizing chemicals.

3. Cooling system

Sprays, whether they use evaporative or direct cooling, require nozzles in order to function properly. According to the nature of the cooling task at hand, one of several possible nozzle configurations may be the most effective option.

4. Tank washing

Cleaning a wide variety of containers, including brewing tanks, chemical reaction tanks, distilling tanks, and food storage tanks, can be accomplished with the assistance of spray nozzle systems. The spray nozzles are versatile and can be used to clean tanks of varying sizes as well as virtually any form of residue.

You can locate a tank cleaning head that washes effectively, efficiently, and consistently superbly, despite the tank's size, environment, or residue. This is something you may look for online.

5. Fire protection

Some spray nozzles' primary purpose is not to put out fires but rather to safeguard valuables from being destroyed by them. For instance, they can be utilised to provide protection for gas tanks, which, if heated, could result in an explosion. In the event that people are stuck in an area where there is a fire, these nozzles can also be utilised to create a water corridor that serves as an escape path for those individuals.

6. Fire prevention

There are some circumstances in which spray nozzles can be utilised to reduce the likelihood of flames breaking out. In most cases, these nozzles only provide a moderate amount of wetness to the target area in order to reduce the number of ignition points in the region.

7. Lubrication

Lubricants are distributed to the desired locations through the use of spray nozzles. Lubrication spraying is a standard procedure in the vast majority of business sectors.

Spray nozzles, in general, make it possible to supply the lubricating fluid in a regulated and controlled manner to a specific area. This is made possible by directing the fluid through the nozzles.

The flow of a fluid can be directed or modified with the help of a device called a nozzle, which is often a pipe or tube with an irregular cross sectional area liquid or gas. Nozzles can also be used to direct the stream.

FAQs: Nozzles

Q. Where are nozzles used?

Ans. Nozzle are mostly used for jet propulsion in rocket and aircraft engineering, extensive shattering and spraying technologies, jet devices and ejectors, gas dynamic lasers, and gas turbines.

Q. What is water spray nozzle?

Ans. The water spray nozzle is a basic tool for generating spray from a fluid flow. The flow, direction, mass, speed, form, and/or pressure of the stream emerging from a nozzle can all be adjusted.

Q. What is the role of jet nozzles?

Ans. Jet nozzles are used to regulate the mass flow rate through the engine, generate thrust, and channel spent fuel back into the open air. The nozzle, located near the rear of the engine, is usually visible, though it may be concealed on some models of jet engines.

Q. What is an air nozzle?

Ans. Nozzles direct a stream of air or steam in a precise and uniform pattern. The spray pattern of most air nozzles is either a flat fan, a solid stream, or a rounded fan.

Q. What is a nozzle in welding?

Ans. Nozzle assists in keeping the contact tip safe from molten metal by directing gas into the welding.

Manufacturers & Suppliers of Nozzles

Company Name | Member Since |

|---|---|

Lakshmi Electro Controls & Automation Bengaluru, India | 19 Years |

Shashi Fluoroplastiks Vasai, India | 18 Years |

Hindmedico Product Private Limited Howrah, India | 18 Years |

Jain Pipe Traders Private Limited Gurugram, India | 18 Years |

Blastech Mumbai, India | 17 Years |

Hari Om Refractories Faridabad, India | 17 Years |

Tough Casting Private Limited Kolhapur, India | 16 Years |

Flamco Combustions (P) Ltd. New Delhi, India | 16 Years |

Mihir Engineering Co. Ahmedabad, India | 15 Years |

Egp Sales Corporation Faridabad, India | 15 Years |

Popular Products