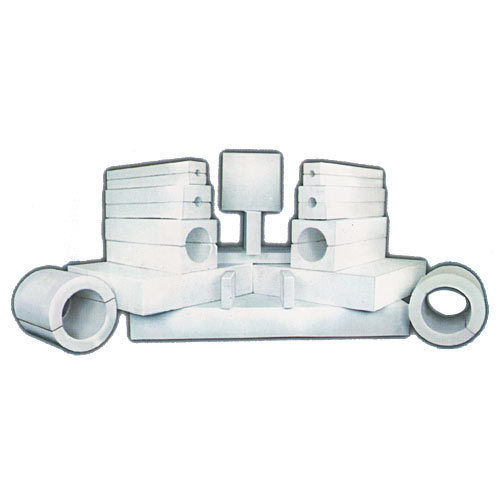

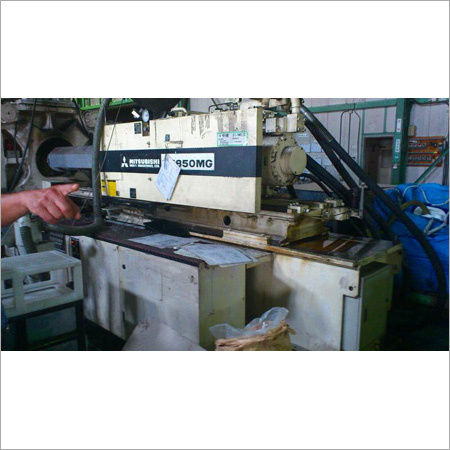

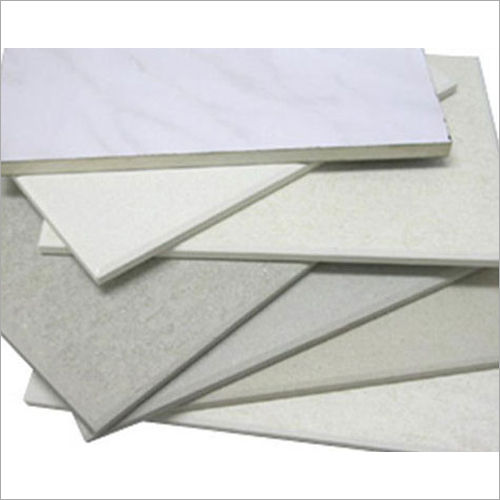

Calcium Silicate It is class A fireproof material.It won't become deformed and peel under high temperature, its raw material has well stability. Non-asbestos micropores Calcium Silicate Board is a new style white and hard insulated material, which has the characteristics of small bulk density, high strength and low thermal conductivity. It can bear high temperature and corrosion, tools can optional cut them. Mineral content: Xonoilite type, hydrous calcium silicate. Main chemical composition: SiO2 47%, CaO 43% and Loss on ignition 8%. 100% non-asbestos. Colour and odour: White and odourless. Volatility: nonvolatile. Solubility in water and organic: 0. Density (bulk, dry): 230 - 320 kg/m3. Stability: Stable under normal circumstances. It can be corroded by strong acid but no toxic substance arises. The main constituents of Calcium Silicate Insulation Board is Xonotlite and reinforced galss fibre, no asbestos. It is a kind of high efficient energy-saving material with temperature limited 1050 cent-degree.Characterised by low bulk density, high specific strength, superior heat resistance, outstanding thermal insulation, excellent durability, chemical corrosion resistance, easy to be cut by saw and easy installation, calcium silicate can be widely used for the insulation of industrial kiln. Areas of application Cement industry: preheaters and cyclone separators, decomposition kiln, tertiary air duct and coolerNonferrous metallurygical industry: aluminum power calciner and electrolysis groovePetrochemical industry: Splitting furnace, catalytic cracking furnace, petroleum pipeline, underground heat-floodingMetallurgical industry(steel plant): hot-rolling heat furnace, cool-rolling mill set, RH vacuum degassing furnace, smelters, hot deformation and heat treatment plantsPower plantreheat stove, pipeGlass industry:melting furnace and recuperator, annealing furnace and cooling channels Density: 200-1000kgs/m3 Temp.Limit: 1000 centi-degree Specification: Maxi 1220 x 1220 x 150mm Application: Industrial furnace or kiln