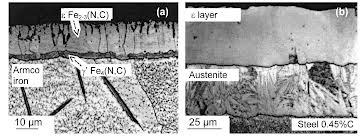

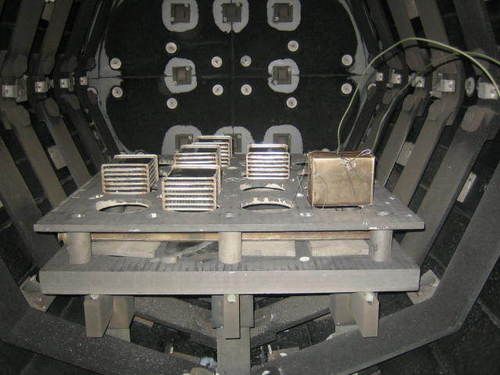

Adhering to the organizational guidelines, our firm is involved in providing world-class Carbonitriding Services. We have established world-class facilities and appointed dexterous professionals, who help us to execute these services as per clients' expectations. Furthermore, strict quality policy is followed while executing these services. By providing these services, we have created a huge clientele across the nation. Our esteemed clients admire our Carbonitriding Services owing to their flexibility, high reliability and cost-effectiveness.Other details:In gas nitriding the donor is a nitrogen rich gas, usually ammonia (NH3), which is why it is sometimes known as ammonia nitriding. When ammonia comes into contact with the heated work piece it disassociates into nitrogen and hydrogen. The nitrogen then diffuses onto the surface of the material creating a nitride layer. This process has existed for nearly a century, though only in the last few decades has there been a concentrated effort to investigate the thermodynamics and kinetics involved. Recent developments have led to a process that can be accurately controlled. The thickness and phase constitution of the resulting nitriding layers can be selected and the process optimized for the particular properties required. Gas nitriding services including case hardening. Capabilities include brazing, bright annealing, carburizing, carbon restoration, carbonitriding, neutral hardening, nitrowear, homogenizing, hydrogen heat treating, induction hardening, normalizing, precipitation & age hardening, sand or glassbead blasting, solution treating, spheroidizing, stress relieving, straightening, cryogenic treating, tempering, tool & die hardening & aluminum heat treating.