Ceramic Beads - Zirconia Silicate, 0.045-0.850mm, White/off-white, High Hardness, Low Dust Production, Ideal For Sandblasting & Finishing

Price Trend: 6.00 - 9.00 USD

Get Latest Price

Minimum Order Quantity :

25

In Stock

Product Specifications

| Application | blasting,finishing,shot peening etc. |

| Product Type | Refractories |

| Types of Refractories | Other |

| Shape | Ball |

| Dimensional Stability | Other |

| Specific Gravity | 3.85 g/cm3 Min |

| Chemical Composition | ZrO2 62-66%,SiO2 25-30%,Al2O3 7-13% |

| Color | white or off-white |

| FOB Port | Tianjin,China or Qingdao,China |

| Payment Terms | Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 3000mt Per Year |

| Delivery Time | 2-3 weeks after payment Week |

| Sample Available | Yes |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | 1. 2*12.5kg Plastic Drum+Paper Box+Pallet2. 25kg Plastic Drum+PalletA Or as per clients' requirement |

| Certifications | ISO9001ISO14001 |

Product Overview

Key Features

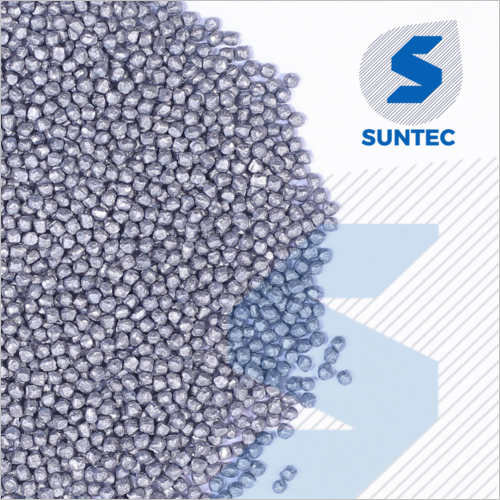

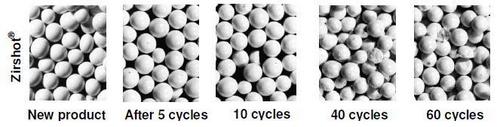

The ceramic beads (also called as zirconia ceramic ball or Zirconia Silicate Beads)are made from zirconium sand, melting and blending in the high temperature mine heat furnace, then made to micro beads by blowing, and finished after processes of cooling, screening, cleaning, selection and magnetic separation.

Its features are high hardness, good elasticity, high gloss and high impact strength.

The main technical data as below:

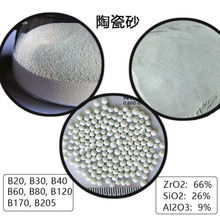

ZrO2 : 62-66%

SiO2 : 25%Max

Al2O3 : 7-13%

Color:White or Off-white

True Denstiy: 3.85g/cm3 Min

Buck Density:2.3g/cm3

Vickers Hardness:700 kg/ mm2

Particle size range:

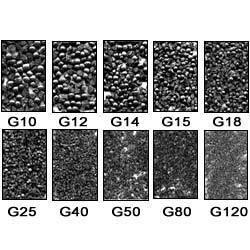

B20:0.600-0.850mm B80:0.180-0.250mm

B30:0.425-0.600mm B120:0.063-0.125mm

B40:0.250-0.425mm B170:0.045-0.090mm

B60:0.125-0.250mB205:0.000-0.063mm

Special specifications can be customized

The advantages compared with glass blasting media:

- Reduced beads consumption (8 - 10 times) against glass blasting media.

- Lower metal surface roughness.

- Less operating pressure and reduced abrasive velocity needed than glass blasting media.

Thus have far less abrasive breakdown and dust generation, results in cleaner working

environment and better operator visibility.

- White color, highly spherical and smooth surface beads.

- Strong mechanical resistance and high toughness, but gentle with equipment and tools

preserving work parts.

- Chemically inert, no metallic contamination for treated parts.

- Low dust production

Applications :

1.Plastic, stainless steel, aluminium alloy, copper and other alloy workpiece--Sandblasting & finishing

2. Steel pipe, copper pipe and other metal pipes , the internal and external wall--Cleaning & Polishing

3. Aviation, ship building, cars, machinery and other metal parts-Shot peening

4.Chemical, food and medicine industries -Liquid and powder--Grinding dispersion

5. The structure of the complex precious metal jewelry-Vibration polishing

6. All kinds of electrical appliances, machinery, chemical industry equipments --Precision ceramic ball

7. Replace the traditional Zirconia (Plastic, metal, etc.)--Cereamic structure

Packing:2*12.5kg Plastic Drum+Paper Box+Pallet

25kg Plastic Drum+Pallet

Or as per clients' requirement

Delivery Time: Within 20 days after payment

Payment Term: T/T or L/C

Company Details

Business Type

Manufacturer, Supplier

Employee Count

25

Establishment

2016

Working Days

Monday To Sunday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

Seller Details

Linfen, Shanxi

Ms Joanna Zhao

Address

Nanban, Zhangzhuang Industrial Park, Fushan county, Linfen, Shanxi, 042601, China

shot blasting media in Linfen

Report incorrect details