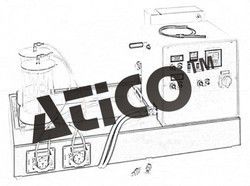

Chemical Reactor Service Unit Apparatus

Price: 500 INR / Piece

Get Latest Price

Minimum Order Quantity :

1 Piece

Brand Name :

Edutek

In Stock

Product Specifications

| Usage | Engineering Testing Equipment |

| Product Type | CHEMICAL REACTOR SERVICE UNIT APPARATUS |

| Application | Engineering Testing Equipment |

| Packaging Details | Carton Box, Export Quality also Available |

| Main Export Market(s) | Asia, Middle East, Africa |

| Main Domestic Market | All India |

| Certifications | ISO 9001, 14001, CE |

Product Overview

Key Features

CHEMICAL REACTOR SERVICE UNIT APPARATUS

Description

This set-up is designed to conduct experiments on different types of chemical reactors on the same service unit. Different types of reactors i.e. continuously Stirred Tank Reactor (CSTR), Plug Flow Tubular Reactor (Coiled Tube Type) and Batch Reactor (which will be supplied on extra cost) as separate units can be installed on the service unit individually one at a time for conducting experiments. Basically this range of small-scale chemical reactors represents the most common types of chemical reactor found in industry. The reactors use the saponification reaction between ethyl acetate and sodium hydroxide. This provides a well-understood and safe reaction for the students to investigate the different reactor types. Each reactor, mounted on a base plate can be attached to the service unit. The appropriate services such as feed circulation, instrumentation for and temperature measurement are connected to the reactor, and it then becomes operational. This service unit comprises feed tanks, rotameters for flow measurement of reactant etc. Compressed air is used for feed circulation. These all things are mounted on a compact and well-designed base for bench mounting. This is self-contained bench top service unit to accommodate the reactors, one at a time, for conducting experiments on the same unit.

Utilities Required

Electricity Supply: Single Phase, 220 V AC, 50 Hz, 5-15 Amp combined socket with earth connection. Earth voltage should be less than 5 volts.

Compressed Air Supply: 2 CFM@1 bar

Water Supply.

Floor Drain.

Floor Area: 2.0 m x 1.0 m

Instruments, Laboratory Glassware and Chemicals required for analysis as per the system adopted.

Technical Details

Feed Tanks: 2Nos. (One each for each reactant)

Material: Stainless Steel

Capacity: 5 Ltrs. Each.

Feed Circulation: By compressed air

Temperature Controller: PID Controller, 0-199.9C

Heater: Nichrome wire Heater.

Hot water Circulator: With water tank and pump to circulate water.

Temperature Sensor: RTD PT-100 Type.

Piping: Stainless steel & PU pipe.

Control panel comprises of: With Standard make on/off switch, Mains Indicator etc.

An ENGLISH instruction manual consisting of experimental procedures, block diagram etc. will be provided along with the Apparatus.

The whole set-up is well designed and arranged on a rigid structure painted with industrial PU Paint

Company Details

Manufacturer and Exporter of all type engineering lab equipment, civil engineering lab equipment, science lab equipment, soil testing lab equipment, concrete Testing Lab Equipment, Vocational Training Equipment, Teaching lab equipment, Pharmacy Lab Equipment, Mechanical Lab for engineering college, fluid mechanic lab for engineering students, etc

Business Type

Exporter, Manufacturer, Distributor, Supplier

Employee Count

25

Establishment

1973

Working Days

Monday To Saturday

GST NO

06AEWPJ6896D1ZU

Certification

AN ISO 9001:2008

Related Products

Explore Related Categories

Seller Details

GST - 06AEWPJ6896D1ZU

Ambala Cantt, Haryana

Director-international Sales

Mr Aditya Kumar

Members since

11 Years

Address

Factory: 70, Edutek House, Main Road Vikaspuri, Industrial Area, Ambala Cantt, Haryana, 133006, India

chemical reactors in Ambala Cantt

Report incorrect details