Cip Systems - Advanced Automated Cleaning Process | Efficient Flushing, Alkaline And Acidic Treatments, Multi-stage Rinsing

Price:

Get Latest Price

In Stock

Product Overview

Key Features

CIP systems are divided in different operations :

1- Flushing in order to eliminate residues

2- Alkaline cleaning operation : alkaline detergents dissolve fat and proteins, and cleaning where harder deposits have occurred

3- Intermediate water rinse

4- Acidic cleaning operation: for neutralizing the caustic remaining on the surfaces of the plant. The acidic detergents remove mineral deposits in the equipment (especially warm areas like in the pasteurizer)

5- Final water rinse: Cold water purges out the residual acid solution

CIP is a closed system where recirculating cleaning solution is applied (often with nozzles) that cleans, rinses and sanitizes equipment. The CIP system is usually automatically controlled and the cleaning sequences are given the optimum timing for efficient cleaning of all parts of the plants.

The sanitary aspects of producing food and beverage products are of extreme importance. Plants must meet high hygienic standards to avoid a product's degradation and contamination during operation, and plant cleaning must be carried out quickly and thoroughly. The cleaning requirements are best met with Cleaning-in-Place (CIP) systems.

Company Details

Focusing on a customer-centric approach, Hangzhou Kehao Machinery Co., Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Processing Machines & Equipment in bulk from Hangzhou Kehao Machinery Co., Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Establishment

2000

Related Products

Explore Related Categories

Seller Details

Hangzhou, Zhejiang

Sale Manager

Mr. Jing Wong

Address

Xiaoshan Economic Development Zone, Hangzhou, Zhejiang, 311222, China

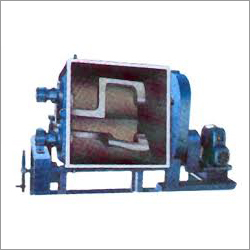

sigma mixer in Hangzhou

Report incorrect details