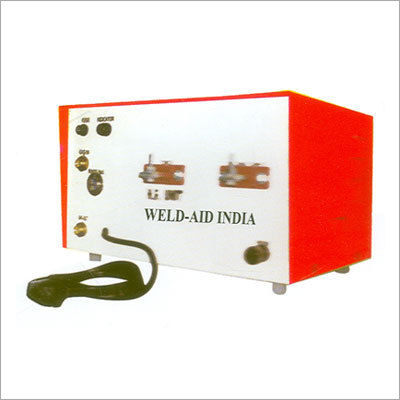

ProcessGas Metal Arc Welding (GMAW) is frequently referred to as MIG Welding is a Commonly used high deposition rate welding process Wire is continusly fed from a spool MIG welding is therefore referred to as a semiautomatic welding process.BenefitsHigher deposition rates than SMAWLess Operator skill requiredLong welds can be made without starts and stopsMinimal post weld cleaning is requiredAll position capabilityFeaturesWelds mild steel, Aluminium & Stainless steel wire & Bronze Alloy WiresSuitable for solid wires as well as flux cored wiresEasy connection system for torch plugin to wire feederCoarse/Fine Controls for proper selection of voltageSleek & most flexible torchSpecification Model SP - 250 Sp - 400 SP - 600 Welding current Upto 250 Upto 400 Upto 600 Open circuit 18 - 38 18 - 52 18 - 56 Maximum Continous Welding Current @ 60 % Duty Cycle AMPS 250 400 600 @ 100 % Duty Cycle AMPS 180 315 480 Input Supply Rating 415/ 3PH, 50 Hz 415/ 3PH, 50 Hz 415/ 3PH, 50 Hz @ 60 % D.C. KVA 8.8 22.5 35 @ 100 % D.C. KVA 6.5 17 27 Cooling Forced Air Forced Air Forced Air Insulation F F F Dimension (LxWxH) 770x440x660 830x490x730 830x540x730 Weight KG 105 200 840 Wire size mm Steel 0.8, 1, 1.2 0.8,1.2, 1.6 1.2, 1.6 & 2 Wire size mm Aluminium 1.2 1.2, 1.6 1.2, 1.6 Speed Range 0 - 18 0 - 18 0 - 18 Drive Type 2 Roll 2 Roll 4 Roll Roll Spool Size Spool Size Spool Size Overall Dia mm 300 300 300 Bore mm 50 50 50