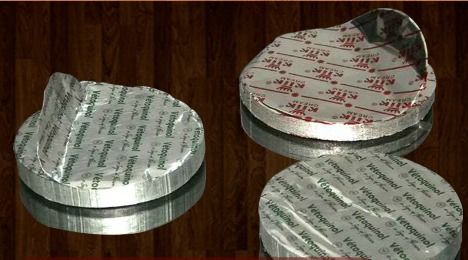

P { margin-bottom: 0.21cm; } With the state-of-the-art and efficient workforce, we bring forth our customers finest quality Lidding Foil. This foil is manufactured using high quality raw material sourced from trusted vendors of the market. Owing to its superior finish, high strength and moisture resistance, these foils are highly appreciated in the market. Lidding Foil is widely used for sealing jars, glasses, cups and various other containers. These foils are available in the market at very reasonable rates.Other information: Soft, fully annealed Aluminium alloy AA-8011 conforming to Aluminium Association specification. The foil can have both side surfaces bright or one side bright and the other side matt as desired by the customer.Technical Specifications Density Of LDPE 0.917 g/cc Peel Strength OfLamination: 200 g/15 mm min. Seal Strength Bet. Top & Bottom Foil: 450 g/15 mm min. Printing And LacquerCoating: Printed as per text, layout and approved by the Customer. For non-printed specification, clear Lacquer to be coated as a protective coating and good printability. Printing inks and lacquer coatings are capable to withstand 180 deg. C for 1 sec. dwell time. Configuration: Printed and Unprinted Pharma Foils are available in the reel forms. Unprinted pharma foils are also available as Jumbo roll. Winding Direction: Generally, printed or clear lacquer side is out in the finished reel. Core: Material options (a) Plastic (b) Aluminium (c) Card BoardCORE ID: 76 mm +/- 0.5 mm. The length of the core is equal to the width of the web. Splices: Butt type made with 25 mm pressure sensitive tape. Reel Outer Diameter: 250 +/- 10 mm for slit material. 400 +/- 10 for Jumbos. Reel Wander: Within +/- 1 mm Reel/Web Width: Plain : 45 mm to 800 mm with a tolerance of +/- 0.5 mm.Printed: 45 mm to 600 mm with a tolerance of +/- 0.5 mm. Joints Per Reel: Maximum 2. Average less than 1. Pin Holes: Nil.