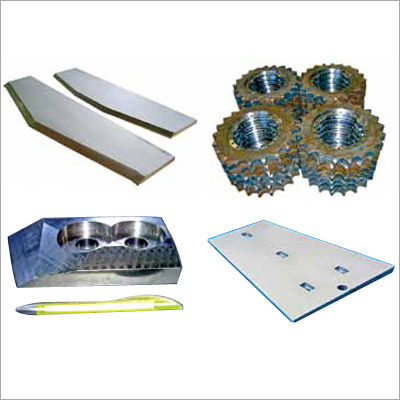

Datasheet Miilux 400 - 450 - 500 - 530Miilux -products are dimensionally accurate, ready for installation abrasion resistant components and abrasion resistant steel plates. At production of components, hardening is carried out as the last work phase which makes the products hard from edge to edge and extends length of products life. When making order of Miilux -products you can tell your request for extra marking, extra tests, bundle, packing and unloading information etc. depending your specific needs. ApplicationsWearing steel plates, lip plates for showel buckets, crusher sidecuts and other wearing parts, gravel and stone platform structures, wearing parts of mining machines, other components according to customer's requirements.Technical Specifications Chemical Composition Content % maximum(ladle analysis) Steel grade Thickness C Si Mn P S Cr Ni Mo B Milux 400 5-30mm 0,20 0,70 1,70 0,030 0,015 1,50 0,40 0,50 0,004 Milux 400 30-120mm 0,24 0,70 1,70 0,030 0,015 1,50 0,70 0,50 0,004 Milux 450 5-120mm 0,26 0,70 1,70 0,030 0,015 1,50 0,70 0,50 0,004 Milux 500 5-60mm 0,30 0,70 1,70 0,030 0,015 1,50 0,80 0,50 0,004 Milux 530 8-40mm 0,34 0,70 1,70 0,030 0,015 1,50 0,50 0,25 0,004 Typical mechanical properties and carbon equivalent Steel grade Thickness Yield strength Rp 0,2 N/mm2 Tensile strength Rm N/mm2 Elongation Impact strength charpy V-40oc Longitude Hardness range HBW CEV Milux 400 5-12mm 1000 1250 10 40J 360-420 0,45 Milux 400 12-30mm 1000 1250 10 30J 380-450 0,45 Milux 400 30-120mm 1100 1400 8 30J 380-480 0,45 Milux 450 5-30mm 1200 1450 8 25J 425-475 0,45 Milux 450 30-120mm 1200 1450 8 25J 425-475 0,45 Milux 500 5-60mm 1250 1600 8 25J 450-540 0,45 Milux 530 8-40mm 1350 1750 8 20J 490-550 0,45 Test report Test report EN 10204-2.2 which shows chemical composition in hot rolled condition before quenching but it doesn't tell mechanical properties test results. Attachment of test report is hardness test as every production run.TestingBrinell hardness test, HBW according to EN ISO 6506-1, on a milled 0.5-2 mm below plate surface is done per every production run. New hardness test is done every time when production parameters change.TolerancesHot rolled plate products: EN 10051 Plate products: EN 10029 Class ASurface qualityEN 10163-2 requirements according to Class A3. Repair welding is not allowed.Dimensions and delivery conditionMiilux -products are supplied in plate thicknesses of 5-100 mm. Maximum width and length for the delivered plates are 2500 mm and 6100 mm. Miilux -products can also be delivered as ready to installation components in a way the deal and order says.