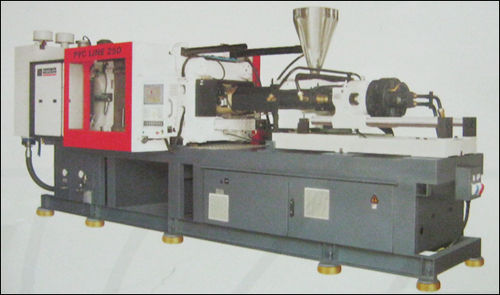

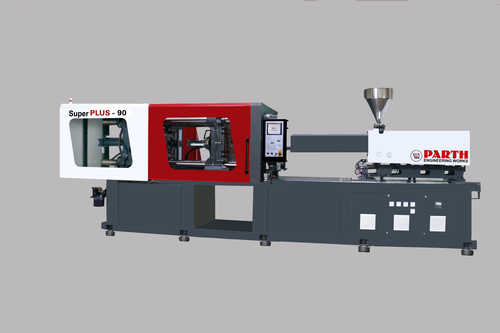

Delta

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Available in : MT - 30, 50, 80, 110, 125, 150, 180, 200, 225, 275, 300, 400, 440 AND 500.

Takes you Closest to Perfection in

PrecisionDesign

and construction concepts used in plastics injection moulding machines

widely differ.

Clamping

unit - Direct hydraulic clamp. Hydro-mechanical clamp. (toggle clamp and

other variants).

Injection unit Twin cylinder, in line injection cylinder.

Hydraulics Digital, Analog (proportional).

The

proponents of each concept spoke out its favour with missionary fervour to

win followers. Concepts did not stay as concepts, they became faith.

In the

early days of development, each design approach had its own advantages. With

the advancement in hydraulic and microprocessor technologies the margin of

difference in advantages reduced, boundaries vanished. Proponents mellowed

down.

Manufacturers of machinery left it to the customer to choose. Customer

became the ultimate arbiter.

However, all through these developments, there was one concept uniformly

accepted by all ad not contradicted by any: the fact that moulding a

quality component within a narrow band of deviation i.e. to a consistent

high precision requires closed loop control of

injection function.

The

dynamism of the market comes from the change, and, the people who embrace

that change will be very successful.

Globalization has made the world a single marketplace, and, intensified the

competition. Performance pressure- economic as well as social -have

compelled all of us to accept this change and make best out of the opportunities

offered. In this changing scenario matter of immediate relevance to us is

the fast spreading trend in the industry - global sourcing, and, produce

where the market is.

It is now in vogue amongst OEMs to move the mould to different global

manufacturing locations and produce parts for the local market needs, while

guarding the product quality fit to the brand image.

Here the advancement in technologies comes to our help. The

success of moulding process depends on the controllability and repeatability

of injection process to avoid drift of parameters. Machines clones make it

possible to produce identical quality components with least experimentation.

Function closed loop control clones the Injection Moulding Machines and

help to produce consistent quality mouldings every time, at every location.

function "Closed Loop Controlled" IMM

configured & constructed to produce consistent high quality mouldings every

time, at every location

CLAMP

Adjustable

individual Pressure Setting of each stage

Position

based acceleration / deceleration for accurate position Switching

and control of speeds and pressures

Programmable

Clamp position with its feedback by linear transducer

Programmable

Ejector Stroke, Pressure and Speed

Proportional Speed Control with 5 closing and opening speed

Quick

auto Clamp forces setting

Safety Guard suitable for Robot / Sprue picker

Sensitive Mould Protection with try again circuit

Stage wise Actual Time Display

Insert Moulding

INJECTION

Injection Velocity and Pressure Steps (6 Speed and 15 Pressure profile)

Adjustable Profile to switch over from fill to pack based on Position,Time

and Cavity pressure

Aluminium

Chequered Plate provided below Purge area

Availability of auto heat startup and shutdown with timer based sprue

break facility

Choice extended for Injection decompression before / after refilling or

both

Extruder rpm adjustment on screen and actual rpm display 5 stage RPM & back pressure control through screen

Eyebolt provision for Barrel lifting

Linear position Transducer assistance for real time read out and accurate Control

Nozzle Contact activation force by Limit switch

PID

Control Algorithms for barrel heating zone

Sprue break feature with timer

User

Friendly design for Cold slug removal, Semi auto purge, Intrusion moulding

EJECTOR

Sequential

Ejector, speed adjustable through screen

Ejector

Stay Forward

Intermediate

Retract set point

Linear

Transducer provided for ejector position read out

Pulsating

Ejector Strokes with ejector forward / retract dwell timer

Two-stage

Ejector forward profile with soft eject

TEMPERATURE CONTROL

Accurate

PID Temperature Controls settable through operator panel for nozzle and

barrel zones

Actual Current Display of individual heating zone with heater failure

detection

Feed

Throat Temperature Indication

Heat

standby after set number of cycles

High/Low Temperature Alarm Bands

Set

and Actual Temperature data with bar graph

Soak

timer for Cold start protection

HYDRAULICS

Hydraulic

Controlled Variable Volume Pump

Continuous oil filtration with 10 micron filter and audiable alarm for

filter clogging

Ergonormic hydraulic layout for easy approach

Pre-

heating circuit for hydraulic oil

Low

oil level monitoring

OPTIONAL FEATURE

Hydraulic

and Pneumatic Core pull

T

Slot Platens (80 500 T)

Hydraulic

and Pneumatic Mould gate

Hydraulic

and Pneumatic power gate (275 T onwards)

Auto

Toggle Lubrication (80 - 440T)

Air

Ejection

Jam

bar

Electrical

Unscrewing Interface

Feed

throat Temperature Control

Bimetallic

Barrel

Coated

Injection Screw

Injection

switch over by Digital external input viz. Gas assisted injection

Injection

switch over by Analog external input viz. Injection pressure / Cavity

pressure

Insulated

Heater Bands (32mm frame & above)

Eject

Retract Verification by Limit switch

RPVC/CPVC

Package ((32mm frame & above)

Host

Computer Interface

Good

/ Defective Part Signal

Water

Battery with Temperature indicator

SPI

Robot Interface

Sprue

break with Limit switch

Closed

loop injection

Nozzel

Contact Force by Pressure switch

Ejector

on Fly ( factory fitted) and Retract Override

PID

Oil Temperature Control

Part

Drop Detect for Single Cavity

Mould

Cooling

USB

Floppy Drive / USB mem stick for Data storing

Gas

Assist Injection

Internet

Connectivity

Company Details

Focusing on a customer-centric approach, Plastics Processing Machine Manufacturer Pvt Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Injection Moulding Machine in bulk from Plastics Processing Machine Manufacturer Pvt Ltd at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

200

Establishment

1996

Working Days

Monday To Sunday

Certification

ISO 9001

Related Products

Explore Related Categories

Seller Details

Ahmedabad, Gujarat

Vice President- International Sales

Mr. Jagdish Bhandari

Address

Plot no. 93/2 & 94/1, Phase-1, G.I.D.C., Vatva, Ahmedabad, Gujarat, 382445, India

other products in Ahmedabad

Report incorrect details