Deodorization Tower - Stainless Steel, 50-1000 Ton/day Capacity | Plc Controlled, Automatic Operation, High-temperature Steam Distillation

Price: 2500 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Type | Oil refining equipment |

| Material | Rice bran |

| Production Capacity | 50-1000 Ton/day |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Control System | PLC Control |

| Voltage | 220 Watt (w) |

| Color | Other |

| Warranty | 5 years |

| FOB Port | Qingdao |

| Payment Terms | Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA) |

| Supply Ability | 1000 Tons Per Day |

| Delivery Time | 30 Years |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Australia, Central America, Middle East, South America, Asia, Africa |

| Main Domestic Market | All India |

| Certifications | ISO9001:2008, SGS,etc. |

Product Overview

Key Features

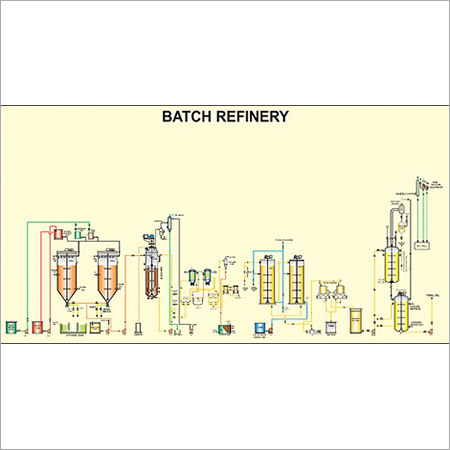

Product Introduction: Deodorizing is the final stage in Edible Oil Refining Process in order to remove the small molecule odor organic matter, the odoriferous material, the free fatty acids and other undesired minor components in oil by steam distillation under condition of high temperature and vacuum to produce bland oil with a good shelf life. It needs be equipped with vacuum distillate, capture, high temperature heat exchange system etc.

Deodorization and Dehydration Section: General speaking, the crude oil doesn't smell good, it will affect oil storage and the selling price. So we usually use the direct steam to get rid of odors. At the meanwhile, there is about 0.5% water content in refined oil, because of the high temperature in the deodorization tower or pot, dehydration section is also finished in this part.

In common, the terrible smell of the crude oil will affect the oil storage and price. In the oil deodorization process, we remove off some terrible flavor substances by means of steam distillation in the process of high temperature and high vacuum conditions. And the oil deodorization process also can be applied to other oil seeds, such as peanut, soybean, cottonseed etc.

Operating Principle: It begins to heating after the decolorized oil pumped into the deodorization pot or the deodorization tower. When the temperature reaches above 260, the direct steam is added to take the odors away. At the same time, the 0.5% moisture in the oil which is produced during rinsing section needs be took out.

Key Factors :

1) Temperature: Increasing the temperature causes a rapid increase in the vapor pressure of the odor substances, it can reduce the amount of direct steam, the peroxide is also beneficial to the removal of the decomposition of carotenoid. High temperature for deodorization is favorable, but it is limited, too much will have adverse effects.

2) Vacuum: Vacuum high, you can reduce the amount of direct steam to reduce deodorization time, reduce the loss of fat hydrolysis, can be obtained free fatty acids containing low refined oil. There is also help prevent high temperature oxidation grease. Generally use three steam jet pump, if necessary, available four steam jet pumps.

3) Steam Rate: If the rate is high, it can shorten the deodorizing time. Empirically derived optimal conditions deodorized oil by the amount of steam was 125 kg/hr.

4) deodorization Time: The Shorter time is better, but also need to remain for some time in the deodorization temperature (called dwell time) in order to improve the stability of oil and fat. Usually intermittent deodorization need 3-8 hours, continuous deodorization 15 to 20 minutes.

Craft Features :

1) It is the mainly equipment of deodorization section, divided into the tower type, packing type, combined type etc.

2) All stainless steel is fully closed structure, long service life, less steam consumption, short deodorization time and good oil quality.

Company Details

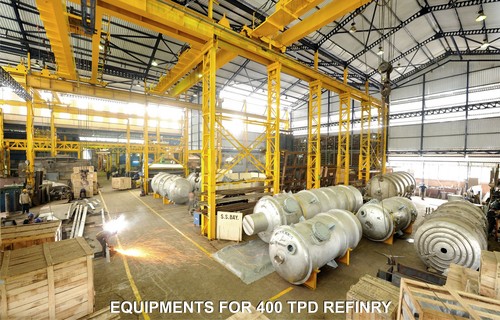

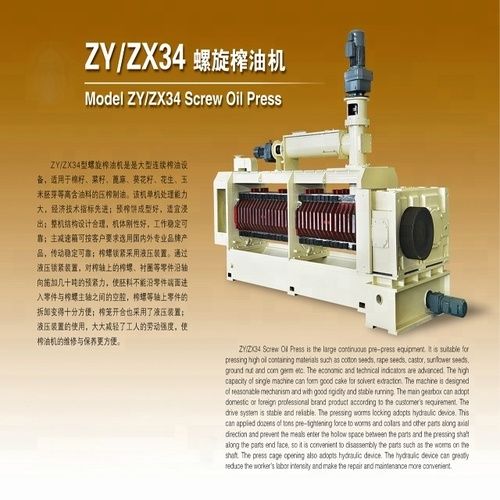

Henan Huatai Cereals And Oils Machinery Co.,Ltd. was founded in 1950,whcih is a large-scale oil machinery manufacturing enterprise integrating R & D, design, manufacture and installation as one of the major grain and oil machinery manufacturing enterprises in China.Our company headquartered located in Huaxiang County Industries,Henan Province,China,covering 100,000.00 square meters. Huatai machinery has developed projects including large scale oilseed pretreatment and pressing, oil extraction, oil refining and oil fractionation production line project,conveyor equipment project,corn/maize flour, grits, germ milling machines and corn processing lines,biodiesel technology,cottonseed, rice bran and soybean protein technology, and Palm Oil processing lines,etc. One of the most largest Cooking oils factory in China. Production of grain and oil equipment solutions from A to Z. Huatai is a factory with more than 60 years experience. More than 100,000 square meters. Over 580 professional employees. 8 Large-scale workshop, 120 production equipments. Henan Huatai Cereals And Oils Machinery Co.,Ltd is committed to R&D of new efficient oil machines, manufacturing customer oriented oil machines, and leading the development direction of the world's most advanced grain processing machines and oil processing machines. We are reply on technology and innovation, constantly developing new type oil machines and equipment in order to achieve worlds advanced level.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

500

Establishment

1950

Working Days

Monday To Sunday

Certification

ISO9001, SGS

Related Products

Explore Related Categories

Seller Details

Zhengzhou, Henan

Accepts only Foreign inquiries

Manager

Ms Dora

Members since

6 Years

Address

B26 No.1, Cuizhu Street High-Tech Zone, Zhengzhou, Henan, 450000, China

edible oil refinery plant in Zhengzhou

Report incorrect details