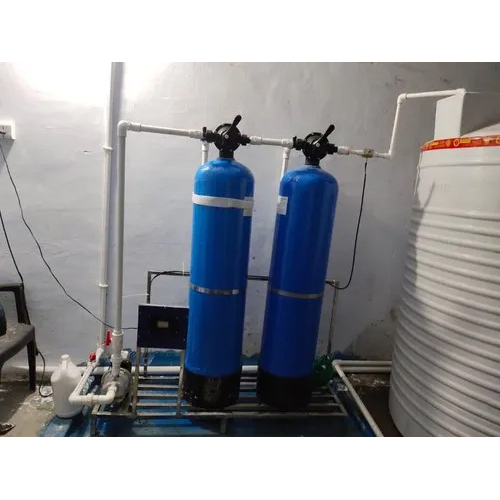

Dm Plant - Acid And Caustic Regenerated Ion Exchange Resins , Strong Acid Cation And Strong Base Anion Combo For High Purity Water Treatment

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Color | Green |

| Resin Type | Cation & Anion |

| Capacity | Variable |

| Dimensions | Variable |

| Usage | Demineralizing water for industrial processes |

| Pressure Rating | 100 PSI |

| Features | Water Demineralization, High Purity, Resin Based, Commercial Scale, Efficient Process |

Product Overview

Key Features

DM PLANT

The demineralization process utilizes acid regenerated cation resin & caustic regenerated anion resin to remove minerals from water.

Demineralization on a commercial scale became possible after resin manufacturers developed methods of mass producing a new form of ion exchange resin. When regenerated with caustic (NaOH), this resin removed silica and carbon dioxide from the effluent of a zeolite resin operated in the hydrogen cycle. A standard cation resin of the type commonly found in zeolite softeners, which is regenerated with sulfuric acid as opposed to salt (hence: hydrogen cycle cation), is called a strong acid cation resin. An anion resin with a strong affinity for silica and carbon dioxide is described as a strong base anion resin. An offshoot of the strong base anion resin development was the production of a chemically different resin with a strong affinity for strong-acid anions: sulfate (SO4), chloride (CI), nitrate (NO3), phosphate (PO4), etc. This was called a weak base resin. The weak base resin does not remove silica or carbon dioxide, as does the strong base resin. Therefore, it cannot be used alone to produce the water purity demanded by high-pressure steam plant operations. Less caustic is required to regenerate the weak base resin and it is often coupled with a strong base resin in the same vessel to produce the most economical anion unit operation. The weak base resin is always loaded into the vessel last when the unit is readied for downflow service.

Putting the weak base resin on top of the anion resin bed uses its higher capacity for strong acid removal to insure that the strong base resin can concentrate on removing the weak acids associated with the carbon dioxide and silica (carbon and silicic acids).

The cation and anion vessels of a demineralizer train are piped in series so that the effluent of the cation unit enters the top of the anion unit and the discharge from the anion unit goes to the treated water header or into a polishing unit.

Company Details

Focusing on a customer-centric approach, FREEION ENGINEERING has a pan-India presence and caters to a huge consumer base throughout the country. Get Water Treatment Plants from FREEION ENGINEERING at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Establishment

2001

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Gandhinagar, Gujarat

C.E.O.

Mr. Keyur Thakkar

Address

3, SF, Hariram Enclave, B/h Raison Petrol Pump, Kudasan, Gandhinagar, Gujarat, 382424, India

dm water plant in Gandhinagar

Report incorrect details