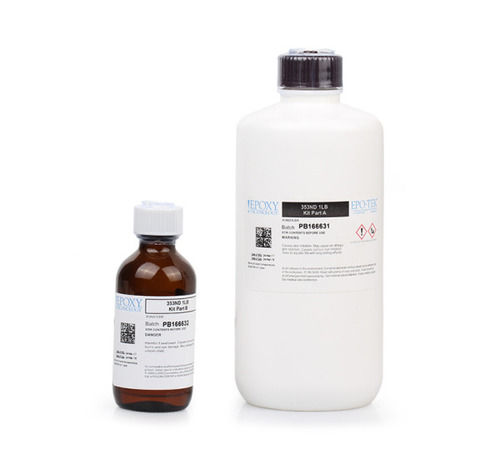

Epo-tek Fiber Optic Epoxy 353nd - 1lb Volume, Amber Color | High-temperature Two-component Adhesive For Semiconductor And Medical Applications, 10:1 Mixing Ratio, Long Pot Life

Price:

Get Latest Price

In Stock

Product Specifications

| Shelf Life | 1 Years |

| Color | Amber |

| FOB Port | Shenzhen |

| Payment Terms | Telegraphic Transfer (T/T), Others |

| Supply Ability | 500 Per Month |

| Delivery Time | 8 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | paper carton with foam |

| Main Export Market(s) | Asia, Australia, North America, South America, Eastern Europe, Middle East, Africa |

Product Overview

Key Features

2. Storage of 353ND Epoxy, EPO-TEK 353ND Part A & B requires storage at room temperature when not mixed, without refrigeration. If stored below 0A C, it must be warmed at room temperature for at least 3-4 hours before A & B mixing to prevent moisture from generating in the epoxy and to avoid bubbles during solidification.

3. Fiber optic EPO-TEK 353ND Part A & B mixing process: As 353ND Part A & B is packed in 4g A-Pack plastic bags, A & B components have been divided according to proportion. Squeeze the bag vigorously from the end of component A to allow the resin to move towards the seal of component B. Press hard so that the resin can break through the interlayer. Then fix the end of the plastic bag and run the resin from beginning to end until components A and B are completely mixed. Cut the end of the plastic bag and extrude the mixed 353ND for application. If packaging is in large-volume packaging (such as tin cans, plastic bottles, or glass bottles), shake parts A and B separately, then mix 10 parts of Part A with 1 part of Part B in glassware and mix well. If a large amount of bubbles are found after mixing, go through the defoaming procedure before application. There are two types of deaeration methods: vacuum deaeration and centrifugal deaeration.

4. Fiber optic epoxy 353ND can be used within 4 hours after mixing (Pot Life), and the amount used should be controlled to optimize resin technology performance. Epoxy Technology Inc. recommends that the dosage should not exceed 25g each time. The curing time and temperature data for user reference: 60A C for 1.5 hours, 80A C for 15 minutes, 100A C for 5 minutes, 120A C for 2 minutes, and curing at 150A C for 1 minute. Curing starts at 200 seconds for the first 10 seconds. Additional curing temperature and time provided above are for reference only. It is recommended not to cure at a temperature above 150A C.

Application:

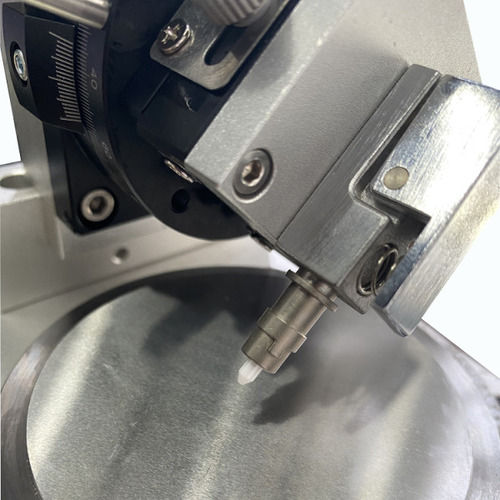

1) Epo-tek 353ND Epoxy is a two-component epoxy resin with a solid content of 100%, resistant to dissolution and erosion by various solvents and chemicals. It is an ideal adhesive for optical fiber, metal, glass, ceramics, and most plastics.

2) Unique characteristics of epo-tek 353ND: Long operation time, easy to penetrate into optical fiber bundles, amber becomes dark red during curing, helping to determine full cure through color rather than time, low skin allergy.

3) EPO-TEK 353ND is suitable for use in thin films and slightly thick films. For thicker applications, it is best to gel at room temperature and slightly above, then increase the temperature and solidify in a short time.

Specifications:

- Model Number: Fiber optic epoxy 353ND

- Mixing Ratio: 10:1

- Applications: Fiber Optic Connector

- Volume: 1LB

- Shelf Life: 1 year

- Packing Specification: Group A + Group B

Company Details

SHENZHEN ZKS TECHNOLOGY Co., Ltd is a leading worldwide manufacturer and supplier of fiber optic products. Our main products include:Patch cord production line equipment, Fiber optic

polishing consumables, Fiber optic polishing fixture,Fiber tools, fiber optic cleaning products,

patch cord, cable,etc. Our company adopts advanced manufacturing technology, high precision

production and inspection equipment. Meanwhile, we strictly execute RoHS, CE and ISO9001-2008.Our products have been exported to many foreign countries like France, Italy USA, Brazil, Korea,Russia etc. Adhering to the services of "Quality comes first, Service - Oriented", our company will keep on providing finest products as well as timely and satisfactory after-sale service.

Business Type

Exporter, Manufacturer, Distributor, Supplier

Employee Count

20

Establishment

2020

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ZKS logo

Related Products

Explore Related Categories

Seller Details

Shenzhen, Guangdong

Manager

Ms Marine Li

Address

903-108, Building A2, No. 2533, Sightseeing Road, Fenghuang Community, Fenghuang Street, Guangming District Shenzhen, Guangdong, 518107, China

epoxy glue in Shenzhen

Report incorrect details