Ethyl Acetate Manufacturing Plant Services

Price: 20000000.00 INR / Unit

(20000000.00 INR + 0% GST)

Get Latest Price

MRP:

20000000.00 INR / Number

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Payment Terms | Cash in Advance (CID) |

| Supply Ability | 1 Per Month |

| Delivery Time | 1 Months |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Asia, Central America, Africa |

| Main Domestic Market | All India |

| Product Unit | 1 Number |

| Price Type | fixed |

| Max Quantity | 100 |

| Returnable | No |

| Pkg Box Breadth | 10.00 cm |

| Unit Type | Number |

| Brand Name | ChemSepT Engineering Pvt Ltd |

| Stock Quantity | 5 |

| Pkg Box Height | 10.00 cm |

| Packsize | 1 |

| Min Quantity | 1 |

| Currency | INR |

| Price | 20000000.00 INR (Approx.) |

| Moq | 1 |

| MRP | 20000000.00 INR |

| Mop | 1 |

| Pkg Box Length | 10.00 cm |

| Minimum Order Quantity | 1 |

| Minimum Ordered Packs | 1 |

| GSTIN | 0% |

Product Overview

Key Features

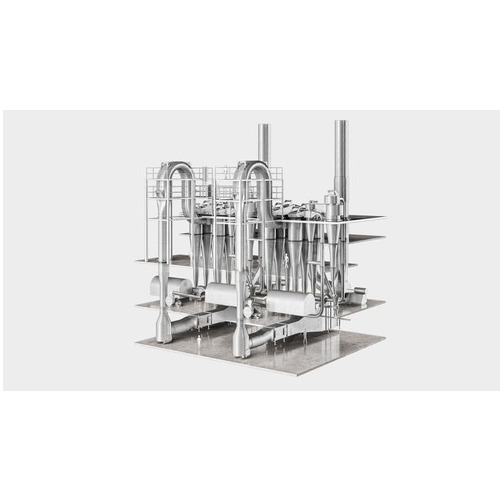

We have gained immense appreciation among our clients for our manufactured and supplied assortment of Ethyl Acetate Plants. In this plant, acetic acid and ethyl alcohol is mixed in a balanced proportion through a preheater to a kettle reboiler for distillation purpose. This plant is known for its robust construction and ability continuously running at even high speeds.

Applications:

Liquor industry

Chemical industry

Pharmaceutical industry

Paint industry

Features:

Resistivity to adverse conditions.

Easy operation

Dimensional accuracy

High tensile strength

Description:

Ethyl acetate is a product of esterification reaction between ethyl alcohol and acetic acid.

The reaction can be represented by CH2CH2OH + CH3COOHa - > CH3COOC2H5 + H2O

Acetic acid and ethyl alcohol are sent in a fixed proportion through a preheater to a kettle reboiler. Small amount of catalyst is added into the kettle. The reaction products are carried to the top of the column as an azeotrope, condensed and pass to a decanter. The top over flow from the decanter is partly given as reflux.The remaining part of the top over flow along with bottom of the decanter is sent to a mixer. The mixer also receives top product of the recovery column and also partly the top product of E.A.Column. The contents of the mixer after thorough stirring are sent to a settler. Top over flow from the settler is sent to E.A. Column. The product E.A. is drawn from the bottom. The top product of the E.A. Column is sent partly to mixer as stated above. Bottom flow of the settler is sent to recovery column whose bottoms are sent to drain. The top product after meeting reflux requirements is sent to mixer

REACTIVE DISTILLATION:

Ethyl acetate is normally produced by esterification of ethanol and acetic acid. A reactive distillation column, combining the reaction and separation into a single stage, is proposed.Reactive distillation represents an integration of a chemical reaction and distillation in a single multifunctional process unit. Chemical equilibrium limitations can be overcome, higher selectivity can be achieved, and the heat of reaction can be used in situ for distillation. These are the basic advantages of the integration considered.

Ethyl acetate is one of the most widely used fatty acid ester and is a quick-drying solvent with excellent solubility. As an excellent industrial solvent it finds an application as an important component of extractants used for antibiotics concentration and purification and an intermediate in the manufacture of various drugs. This solvent is applied in the manufacture of adhesives, cleaning fluids, nail-polish removers and Metallurgy coated papers, explosives, artificial leather, photographic films and plates.Other applications of ethyl acetate are associated with the manufacture of synthetic fruit essences, flavors and perfumes. It can be used as the standard material and solvent for analytical reagents and chromatography analysis.

Ethyl acetate is produced through esterification of ethyl alcohol and acetic acid. This process is described as an acid catalyzed equilibrium synthesis developed by Emil Fischer.

Company Details

ChemSept Engineering Pvt. Ltd. is a one-stop Engineering Consultancy that offers the complete range of Turn-Key Based Process & Mechanical Engineering Solutions

Business Type

Exporter, Manufacturer, Supplier, Fabricator

Employee Count

100

Establishment

2015

Working Days

Monday To Saturday

GST NO

27AAGCC2910A1ZB

Related Products

Explore Related Categories

Seller Details

GST - 27AAGCC2910A1ZB

Pune, Maharashtra

Ceo

Mr Prakash

Address

Office No. 612, Rama Equator, Near Finolex Chowk, Morwadi, Pimpri, Pune, Maharashtra, 411018, India

industrial distillation columns in Pune

Report incorrect details