Product Overview

Key Features

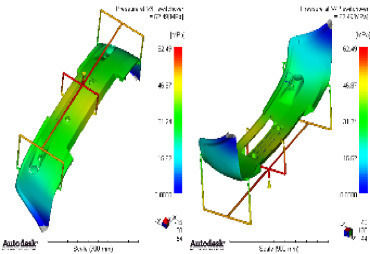

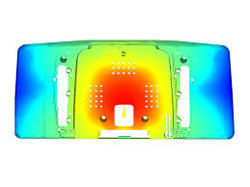

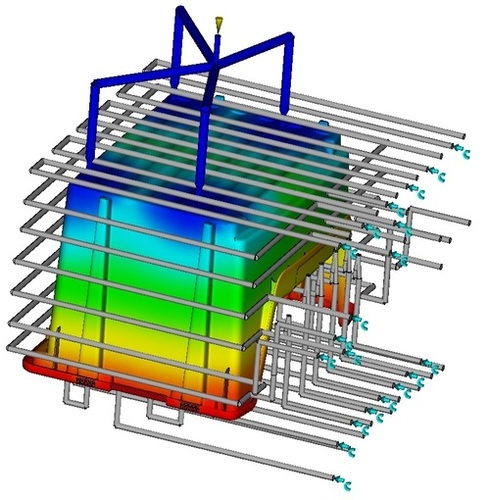

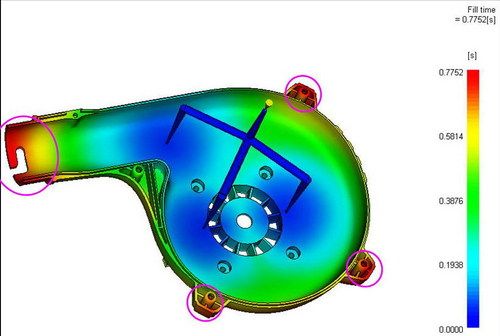

We are the leading service provider in Pune, Maharashtra, India and providing Fill Analysis Service to our valuable customers. We help you determine and visualize the flow front progression to see how the mold fills and identify and eliminate possible defects.

It also helps determine injection pressure and clamp force requirements. It helps optimize part wall thickness to achieve uniform filling, minimize cycle time and reduce part cost. Predict Weld Line Locations and either move, minimize or eliminate them. Identify potential air traps and determine locations for proper mold venting.

Optimize process conditions such as injection time, injection velocity, profile, melt temperature, packing pressure, packing time and cycle time.

Opptum Engineering Solutions Pvt. Ltd. offers engineering services for design, FEA, moldflow analysis, program management, problem solving, and Solutions for diverse industries from automotive, aerospace, consumer, electronics, medical, defense, and energy. and our core strength is its ability to receive, convert and deliver.

All types of assignments for plastic parts.

We are Engineering Resource and Solution Provider

Services in Design

Privately held company Established in 2013,

Completed more than 3000 critical projects,

We have Mechanical Engineers, Polymer Engineers and Tool and Die Engineers.

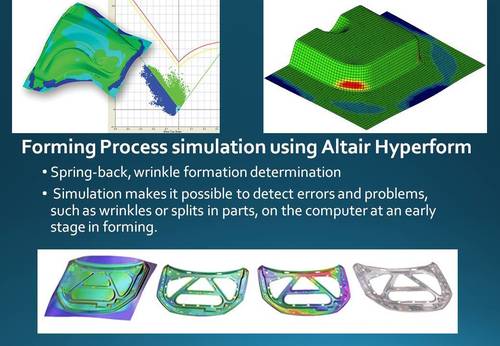

We are supplier of engineering services for the development of plastics products and the simulation of plastic part manufacturing processes.We provide value added services in the development and manufacture of complex plastics parts.

Moldflow Analysis services are handled by experienced team of engineers holding rich experience and expertise in evaluating injection mold design as well as providing solutions for coming up with production of quality plastic parts.

Opptum Engineering Solutions operates the full suite of Moldflow CAE & CAD programs for injection molding advice and undertake Moldflow simulation on the smallest medical device to the largest car instrument panel quickly and efficiently to give customer practical solutions to complex injection molding problems.