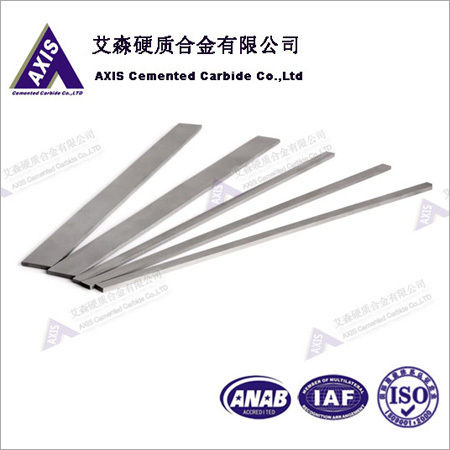

Fine Finished Tungsten Carbide Strips Application: For Water Level Recording

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Tungsten Carbide Strips from Top 10 Tungsten Carbide :

Product Description of Finished Tungsten Carbide Strips from Top 10 Tungsten Carbide

Name : Finished Tungsten Carbide Strips from Top 10 Tungsten Carbide Manufacturer

Main Market : North America, South America, Europe, Mid East, Africa, Southeast Asia, etc.

Application Field : It's widely used for general wood cutters or hard wood cutters, plastic cutting. And it is suitable for the production of various types of motors, electronic progressive dies punches.

Material : 100% pure tungsten carbide

Grade : YG6, YG8, YG4C, YK05, YG8C, YK15, YK20, YG15C

Design & Size : OEM or ODM acceptable

Properties : High hardness and strength, excellent wear resistance

Finish : Sintered, sandblasting or polish

Packing : Our standard packing (paper + carton box or inner box + outer box) or as request

Lead time : Sample date: 5-7 days, mass date: 15-35 days

Shippment : By express( such as DHL, TNT, UPS), by air or by sea

Service : We will follow up goods for our customers and help them to solve problems after sales.

Tungsten Carbide

Tungsten carbide comes from a family of metal matrix composites commonly referred to as cemented tungsten carbide. Comprised of the elements tungsten (W) and carbon (C), tungsten carbide is further enhanced through the addition of a metallic binder such as cobalt or nickel.

Tungsten Carbide Production

Production of tungsten carbide is achieved by mixing the ultra fine powders, compacting to form a shape, green machining to near net shape and then sintering at a temperature above the melting point of the metallic binder. The molten binder surrounds the carbide particles and bonds the matrix together producing an extremely hard and tough composite material. Due to its high hardness and excellent impact resistance, tungsten carbide is commonly used in applications ranging from progressive dies,tooling components, mechanical seal faces, a multitude of wear components for the Oil & Gas industry. The toughness and hardness properties can be tailored to specific application requirements by adjusting the binder content.

Contact us to learn more about the attributes of tungsten carbide and how tungsten carbide can be used in your extreme applications.

The Application of Finished Tungsten Carbide Strips from Top 10 Tungsten Carbide Manufacturer

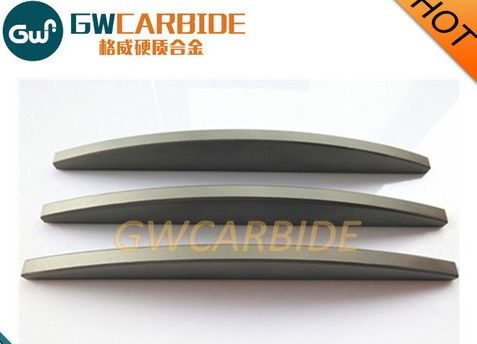

1. Suitable for making cast iron rolls and high nickel chrome roll dressing knives.

2. Suitable for making discharge plates, stamping dies, punches, electronic progressive dies and other stamping dies.

The Advantages of Finished Tungsten Carbide Strips from Top 10 Tungsten Carbide Manufacturer

1. Good wear resistance, good corrosion resistance and high toughness;

2. Extrusion method and HIP sintering;

3. Carbide wear strips Made of 100% pure raw materials;

4. With advanced equipment and process production;

5. All tungsten carbide wear strips pass the process and final inspection;

6. The ability to stabilize and continuously produce;

7. Our carbide wear strips have high quality and good price;

8. Fast stocking capacity and timely delivery.

The Specification of Finished Tungsten Carbide Strips from Top 10 Tungsten Carbide Manufacturer(Various sizes of K20 K30 tungsten carbide wear strips can be customized.And other grades carbide strips are also available.)

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier, Producer

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

Seller Details

Zhuzhou, Hunan

Mrs Cherry Liu

Address

null Zhuzhou, Hunan, China

tungsten carbide strip in Zhuzhou

Report incorrect details