Gypsum Board Production Line - Advanced Pneumatic Shaft And Magnetic Powder Brake | Efficient Slurry Control, Low Heat Consumption Dryer, Full-cycle Monitoring System

Price:

Get Latest Price

In Stock

Product Overview

Key Features

1.Paper supply system:

The special pneumatic shaft;

Magnetic powder brake;

Exact paper connection device;

High definition automatic device;

High definition automatic alignment device;

2.Mixing system:

Mainly consists of paper slurry,foaming agent,starch,water and additive etc;

All slurry has the feedback signal of level indication and chain control each batching process according to the process requirement;

3.Forming system:

This part is mainly the forming of wet gypsum board;

Can be adjusted manually;

4.Conveying system:

This part is composed of two sets solidification belt machine and one conveying roller machine.

The three machines need to run synchronically.

5.Cutting system:

Whole cut control algorithm is achieved by the separate PLC.

6.Transferring system:

This part mainly function is gypsum board acceleration conveying,overturning,transit conveying and lifting.

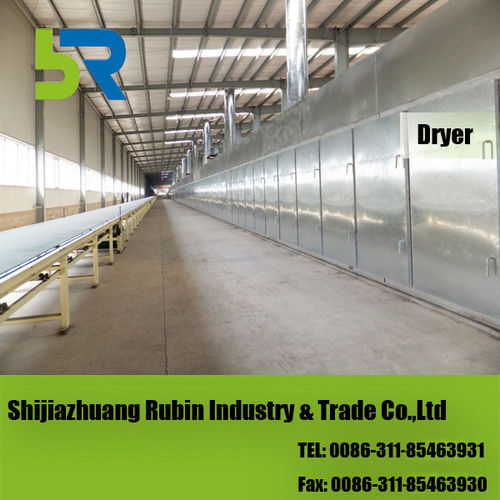

7.Dryer system:

Low heat consumption, heat preservation is good;

8. Finished products converying system:

This part mainly includes fast outlet,sizing and stacking which are all equipped double.

9.Fast outlet system:

Can achieve the equipment failure without stopping.

10.Sizing system:

This part consists of transverse machine,storage roller,board colse folder and sizing device.

11.Stacking system:

This part consists of two sealing machines,stackers.

12.Control center system:

Host part adopts RS VIEW as the monitoring software table to monitor the whole production process.

Company Details

Focusing on a customer-centric approach, Shijiazhuang Rubin Industry & Trade Co., Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Industrial Machinery & Parts in bulk from Shijiazhuang Rubin Industry & Trade Co., Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Establishment

1999

Related Products

Explore Related Categories

Seller Details

Shijiazhuang, Hebei

Ms. Myra Qin

Address

Lemo Building, No.18 Pingan North Street Shijiazhuang, Hebei, 050000, China

gypsum board machine in Shijiazhuang

Report incorrect details