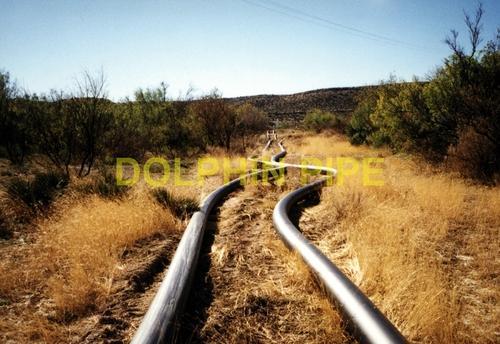

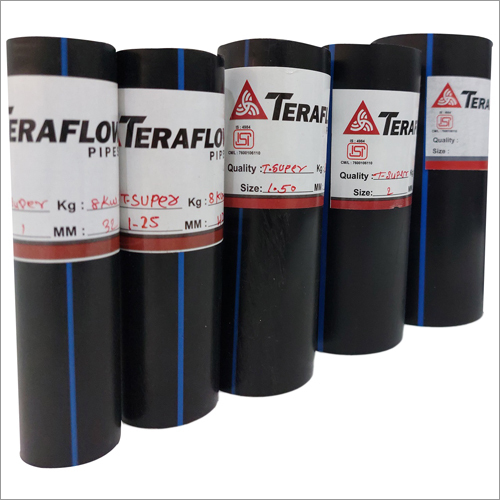

We present our line in the manufacture and export of an apprehended assortment of HDPE Drainage Pipes. Owing to their excellent performance, these pipes are broadly used for the water drainage or drying purposes by numerous industries. Manufactured using topmost quality raw material, top notch technology and worldly tools and machinery, our range assures to be durable, reliable and cost effective. Applications: For PE 63: 3.0 MPA For PE 80: 4.0 MPA For PE 100: 5.0 MPA Advantages: Light in Weight, Long Lasting and Maintenance free Flexible due to elastic in nature and ideal for adapting to uneven ground or displacement Tough due to high flexural and impact strength Suitable to withstand high external loads caused by movement or ground slippage The pipes remain elastic and stay in shape as the load is carried back to the ground In case of deformation occurring over longer period, the tension in the pipe relaxes until there is virtually no tension left On the contrary rigid pipes take on the load and cracks began to appeal which may lead to ultimate failure of the pipes Chemically inert and hence resistant to chemicals and hostile corrosive soils Suitable for acids, alkalis and can be laid in marshy and corrosive soils without any coating and catholic protection Resistant to abrasion and thus suitable for transportation of slurry, boiler ash, ores beach sands, etc. Low frictional resistant to fluid flow and thus saves energy costs for pumping Remain free from incrustation throughout the life span giving better flow always Available Sizes & Pressure Ratings: Ori-Plast is manufacturing HDPE Pipes as per IS 14333:1996 of following sizes and pressure ratings Sizes of outside diameter 63mm to 630mm for all the three grades of materials i.e. PE 63, PE 80 & PE 100 Pressure Ratings of PN 2.5 and PN 16