Cooling Tower & Chilling Plants

(3920 products)![]() Filters

Filters

Industrial Cooling Tower - Heavy Duty Aluminum, 2500 Gallons Capacity | High Efficiency, Low Noise Operation, Durable Design

52000 INR (Approx.)/Piece

MOQ1 Piece/Pieces

Product DescriptionIndustrial Cooling Tower

Akshar Composites

Surat

Pvc Film Fills

Price Trend: 3500-5500 INR/Cubic Meter

MOQ50 Cubic Meter/Cubic Meters

Supply Ability1000 Per Week

Delivery Time2 Week

Cooldeck Industries Pvt. Ltd.

Mumbai

7 Years

Super Premium

Super PremiumWater Chiller Warranty: 1Year

Price Trend: 50000.00 - 100000.00 INR/Unit

MOQ1 Unit/Units

Warranty1year

Shell and Tube Water Cooled Chiller - Copper Cooling Coil, Customizable Dimensions | 75 Ton Refrigerating Capacity, Reliable for Food and Chemical Industries, 12-Month Warranty, 3 Phase Power Supply

Price: 2500000 INR/Number

MOQ1 Number

MaterialMetal

UsageAs per Process requirement

Weight1500 - 1800 Kilograms (kg)

ColorBlue

SizeAs per Process requirement

Water Flowing RateAs per Temperature requirement

Everestt Chillers Private Limited

Coimbatore

Super Bonanza

Super Bonanza2 Years

Brine Chilling Plants - Material: Metal

Price: 100000 INR/Piece

MOQ1 Piece/Pieces

SizeStandard

MaterialMetal

Product TypeBrine Chilling Plants

UsageIndustrial

ConditionNew

TypeBrine Chilling Plants

Unique Air Products

Vadodara

15 Years

Super Premium

Super PremiumFrp Cladding Cooling Tower - Size: Standard

Price: 350 INR/Square Meter

MOQ200 Square Meter/Square Meters

SizeStandard

MaterialFRP

UsageIndustrial

ConditionNew

Power SupplyManual

Everest Composites Pvt. Ltd.

Vadodara

18 Years

Ms Water Cooled Chiller - Color: Black

Price: 57000 INR/Piece

MOQ1 Piece/Pieces

ColorBlack

UsageIndustrial

MaterialMetal

ConditionNew

Warranty1 year

Shree Mangaldeep Sales

Ahmedabad

5 Years

Cooling Tower - Color: Blue

MOQ1 Piece/Pieces

ColorBlue

Product TypeCooling Tower

UsageIndustrial

ConditionNew

TypeCooling Tower

Power SourceElectricity

B S Engineering Machinery Pvt. Ltd.

Kolkata

21 Years

Cross Flow Frp Cooling Tower Capacity: 500 T/Hr

Price: 300000 INR/Set

MOQ1 Set/Sets

Colorother

Product TypeCross flow FRP Cooling tower

General UseAuxiliary Equipment-Utility Equipment

MaterialOther, Stainless steel

TypeBroaching, Drilling, Milling, Turning, Other, Etching, Laser Machining, Chemical Machining

Capacity500 T/hr

Labh Projects Pvt. Ltd.

Ahmedabad

4 Years

Ved Engineering

Noida

12 Years

220 V Cold Storage Plant - Application: Industrial

Price: 1500000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

ColorSilver

Product Type220 V Cold Storage Plant

ApplicationIndustrial

SizeDifferent Size

ConditionNew

Keon Reftec Private Limited

Ahmedabad

3 Years

Air Chilling Plants Application: Oleochemichal

Price: 800000 INR/Unit

MOQ1 Unit/Units

MaterialMetal

ApplicationOleochemichal, Chemicals, Pharmaceutical Industry.

CompressorKirloskar/ Mycom/ J&E Hall/ Bitzer/ Emerson etc.

Singhsons Refrigeration

Mumbai

23 Years

Prefabricated Cold Storage - Application: Industrial

Price: 2500000 INR/Piece

MOQ1 Piece/Pieces

Product TypePrefabricated Cold Storage

ApplicationIndustrial

UsageFor Food Industry

ColorBlue & White

ConditionNew

TypeStorage

Refcon Refrigeration Private Limited

Pune

10 Years

Milk Chilling Plants - Stainless Steel, High Efficiency Cooling System | Designed for Rapid Milk Cooling and Preservation

Price Trend: 500000.00 - 2000000.00 INR/Piece

MOQ1 Piece/Pieces

Payment TermsCash in Advance (CID), Cheque, Cash Advance (CA)

Supply Ability50 Per Month

Delivery Time3 Week

Drycool Systems India (p) Ltd.

Noida

21 Years

Metal Industrial Dairy Fogging System

Price: 25000 INR/Unit

MOQ1 Unit/Units

MaterialMetal

ConditionNew

Nozzle MaterialStainless Steel

New Kalinga Enterprises

Dhenkanal

3 Years

Super Premium

Super PremiumDifferent Available Solar Module Water Tank Structure

Price: 20000 INR/Unit

MOQ100 Unit/Units

UsageCommercial

ColorDifferent Available

MaterialFRP

ConditionNew

Nozzle MaterialStainless Steel

Loknath Engineering

Howrah

4 Years

Industrial Chiller - 230 Volt AC & 440 Volt AC Power Supply, Maximum Temperature -20 to 40°C, Maximum Water Flow 3 to 12 Bar, Brimful Capacity Under Standard Conditions

Product DescriptionPower Supply :230 Volt AC and 440 Volt AC\015\012Maximum Temperature :-20 to40\015\012Maximum Water Flow :3 bar to 12 bar\015\012 \342\200\240 Brimful Capacity \342\200\240\342\200\240 Under Standard Condition

Shapet Induction Private Limited

Rajkot

16 Years

Square Cooling Tower

Price: 70000 INR/Piece

MOQ1 Piece/Pieces

Supply Ability1 Per Week

Delivery Time1 Week

Sample PolicyContact us for information regarding our sample policy

Akshar Composites

Surat

7 Years

High Strength Water Condenser

MOQ5 Piece/Pieces

Payment TermsCash on Delivery (COD), Cheque, Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

Sample PolicyContact us for information regarding our sample policy

Main Domestic MarketMaharashtra

Yantrik Engineers

Pune

7 Years

Frp Cooling Tower Profiles - Color: Multi Color

MOQ100 Piece/Pieces

Product TypeFRP Cooling Tower Profiles

SizeStandard

UsageIndustrial

MaterialFRP

ColorMulti Color

ConditionNew

Plurimo Pultrusion And Composite Private Limited

Ahmedabad

4 Years

Water Chiller Machine Capacity: 5 Ton Ton/Day

Price: 165000 INR/Unit

MOQ1 Unit/Units

Dimension (L*W*H)L - 2.6 X W - 2 X H - 4.2 Foot (ft)

Voltage3730 Watt (w)

Capacity5 ton Ton/day

Excel Filtration Pvt. Ltd.

Ahmedabad

9 Years

Water Chiller - Material: Metal

MOQ1 Unit/Units

UsageIndustrial

MaterialMetal

ConditionNew

Power SupplyElectricity

Cooling TypeAir Cooling

Vishwakarma Engineering

Vadodara

3 Years

Water Chiller

Price: 300000 INR/Piece

MOQ1 Piece/Pieces

Payment TermsCash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA), Cheque

Supply Ability10 Per Month

Delivery Time15 Days

Swastik Enterprise

Ahmedabad

9 Years

Water Online Chillers - Color: Grey

Price: 150000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

ColorGrey

Refrigerating Capacity500 Ltr

MaterialOther , SS 304

ConditionNew

TypeWater Online Chillers

Akshay Industries

Coimbatore

7 Years

Ms Air Cooled Chillers Application: Industrial

Price: 105000 INR/Unit

MOQ1 Unit/Units

Product TypeAir Cooled Chillers

MaterialMild Steel, Other

ApplicationIndustrial

ConditionNew

TypeMS Air Cooled Chillers

Power SupplyElectric

Refricon Hvac Systems

Pune

2 Years

Spectec Techno Projects Pvt. Ltd.

New Delhi

Chiller With Stainless Steel Water Pump - Dimension (L*W*H): 420X420X800 Millimeter (Mm)

MOQ1 Unit/Units

Refrigerating Capacity10A3kcal/h

UsageIndustrial

MaterialAluminum

Weight50 Kilograms (kg)

ConditionNew

Dimension (L*W*H)420x420x800 Millimeter (mm)

Shandong Hg Engineering Equipment Co., Ltd.

Jinan

2 Years

Cooling Tower Water Treatment - Xerodrop Aop Warranty: 1 Year

Price: 200000.00 INR/Plant

MOQ1 Plant/Plants

ApplicationCooling Tower Water Treatment

MaterialOther

ConditionNew

Warranty1 year

Aeolus Sustainable Bioenergy Pvt. Ltd.

Surat

11 Years

High Efficiency FRP Cooling Tower

Price: 28000.0 INR/Units, Units, Units

MOQ1 Units, Units, Units

MaterialFRP

ConditionNew

Mantra Composites

Indore

9 Years

Latest From Cooling Tower & Chilling Plants

Cooling Tower Chilling Plants

By:

V Cool Systems

Cooling Tower And Chilling Plants

By:

D. P. Clean Air Solution

FRP Cooling Towers

By:

Nikunj Reinforced Plastics

Water Chiller For Extruder

By:

Blu Berg

Banana / Mango Ripening Chamber

By:

Amafhh Airconditing Engineering

Pre Coolers

By:

Eakcon Systems Pvt Ltd

Chilling Plant

By:

Techno Plast

Explore More Cities

Ready To Ship Cooling Tower & Chilling Plants

What is a Cooling Tower or Chilling Plant

Introduction

A chiller is a simple cooling device that works by drawing heat away from the coolant and then transferring it to the ambient air. This mechanism, like a cooling tower, is meant to remove heat from the water before it leaves the condenser. Although chillers and cooling towers accomplish comparable goals, the latter are more commonly utilized due to their more compact size and greater flexibility in installation.

It's likely that the system's efficiency will suffer if you use an inefficient cooling method. One of the two tower options available for cooling is a mechanical draft cooling tower. Large fans are used in this tower design to bring in cooler air from the surrounding environment.

What is the Function of Cooling Tower or Chilling Plant

A Cooling Tower Function

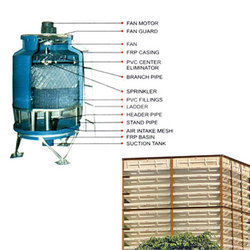

For the purpose of removing excess heat from a coolant (often water) that is being used to cool equipment, process fluids, or structures, a massive heat exchanger unit known as a cooling tower is typically employed. Evaporation of a little amount of water into the air further reduces the temperature of the cooling water. Evaporative cooling describes this method.

To ensure a reliable supply of water for cooling purposes, cooling towers are typically located next to large bodies of water like lakes and rivers.

Water that has been heated in an industrial operation can either be routed through a heat exchanger or condenser before reaching the cooling tower, or it can go straight to the tower. Water is sprayed from nozzles inside the tower onto a fill material, increasing the rate of evaporation due to the greater surface area in contact with the air.

Drift eliminators get rid of the tiny droplets of water that form in the tower air stream as a result of evaporation, and cooling fans inside the tower help with the cooling process.

1. Building a Cooling Tower

Water pumps and a sizable basin are the two main components of a cooling tower. The basin receives the drained water from the system and the pumps supply the water for cooling.

Despite the prevalence of massive cooling towers (often over 200 feet in height and 100 meters in diameter), smaller systems are available for use in more compact locations or atop individual buildings.

2. Uses for Cooling Towers

Power plants, oil refineries, and thermal power plants are just a few of the industrial settings that regularly employ cooling towers. The desired coolant temperature is a crucial consideration when picking between a chiller and a cooling tower.

Conditions in the wet bulb and outside air temperature affect the temperature in cooling towers. In the heat of the summer, a cooling tower's low-temperature coolant can rarely go below 80 degrees Fahrenheit. Chillers can maintain constant temperatures of around 70 degrees Fahrenheit throughout the year.

Industrial Chilling Plant Functions

An industrial Cooling Tower & Chilling Plants is a device used to remove heat from a hot gaseous coolant produced by a process that employs water or another heat transfer fluid. After being heated by the compressor, the used refrigerant is cooled and regenerated by being exposed to cooler air or water from a tower or other external source before being recycled.

Depending on the medium used to remove heat from the system, industrial chillers may be air-cooled or water-cooled. To reverse the phase transition from gas to a liquid, air-cooled chillers expose the hot coolant that has been transformed into a gas (in the evaporator) to ambient air. A cooling tower supplies water for use in water-cooled chillers, which are then used to cool and condense the coolant.

Working Principle of Cooling Tower or Chilling Plant

A great feature of cooling towers and chillers is that they come in a wide range of sizes, making them suitable for a wide variety of applications. Consequently, a smaller chiller and cooling tower can be used together.

When cooling a smaller application or piece of equipment, a water-cooled or air-cooled chiller and a portable cooling tower can be installed on the roof of a factory. Larger water-cooled chillers are often used in tandem with cooling towers.

An effective cooling system consists of a huge cooling tower and a sizable chiller, both of which are used in a microbrewery or power plant. You can expect to make substantial long-term savings if you can afford the initial investments in these two systems.

Central cooling facilities can be built employing these methods in a power plant by positioning the water-cooled chiller on the basement level or the air-cooled chiller on the roof. A cooling tower must be located on the roof at all times for efficient heat dissipation.

However, only extremely big cooling towers benefit from a natural draft and flow of air through the chiller, therefore enormous cooling towers like those found at nuclear power plants must rely on artificial means of circulating air. The airflow in a cooling tower is typically generated by an electrical fan motor. A "Driven or Force Draft" coolant is what you need.

Advantages of Chilling Plant or Cooling Tower

1. Longer Lifespan

In general, chillers that are cooled by water don't need to be replaced as frequently as those that are cooled by air. They are protected from the sun, wind, snow, and ice, as well as extremes of temperature because they are not exposed to the elements outside.

As a result of the cooling tower's consistent operation, especially in the face of trying climatic circumstances, the lifespan of the system and the equipment is extended.

2. Quiet Operation

Water-cooled chillers are virtually silent in operation, in contrast to their air-cooled counterparts, which include ducts and vents that generate noise. Because water is being circulated through the system, there is not the same kind of loud expansion and contraction that is experienced in air-cooled chillers. In settings such as hospitals and schools, where excessive noise might be disruptive to the people present, the ability to operate in a quiet manner is of the utmost importance.

3. Energy Efficiency

When compared to air-cooled chillers, water-cooled chillers have a film coefficient that is anywhere from 10 to 100 times better. This indicates that chillers that are cooled by water do a better job of transferring heat. The end effect for businesses is a reduction in their expenditures for the cost of energy. The plant functions without a hitch thanks to the uninterrupted cooling provided by the circulating water.

In cooling towers, motors operating at low speeds allow for the most efficient use of air in the process of evaporation.

The water goes through a process called recirculation, which ensures that the system is clean and operating at its maximum capacity, while also reducing the amount of energy needed to attain the desired level of production.

4. No Open Space Needed

In order to function properly, air-cooled chillers have to be kept outside, in the open and supplied with a sufficient amount of clean air. Chillers that are cooled by water are housed inside buildings, making them an excellent choice for businesses that do not have adequate access to the outside areas.

5. Safety

Chillers that are cooled by water utilize water as the refrigerant, as opposed to harmful chemicals. People who come into contact with them are consequently less likely to sustain injuries as a result.

6. Less Maintenance

The amount of required maintenance is cut down since there are components that are resistant to corrosion and has a high tensile strength.

7. Save Water

When cooling towers are equipped with an efficient drift eliminator system and air intake louvers, they are able to conserve a significant amount of water during the process.

FAQs: Cooling Tower & Chilling Plant

Q. Which chemical is used in cooling tower and chilling plant?

Ans. The cooling tower and chilling plant chemical include borate, nitrite, and silicate. The second substance is a biocide for use in cooling water. Glutaraldehyde and isothiazolin are the two types of biocides that are used the most frequently to kill microorganisms.

Q. How many types of chiller plants are there?

Ans. Here are the types:

- Water-Cooled Chillers

- Air Cooled Chillers

- Screw Chiller

- Vapor Absorption chillers

- Evaporation

- Vapor Compressor Chillers

Q. What is the function and types of cooling tower?

Ans. When it comes to preventing machinery from overheating and cooling process water, cooling towers are an absolute necessity. Here are the types:

- Crossflow Cooling tower

- Counterflow Cooling Tower

- Natural Draft

- Induced Draft

Q. How do chilled water plants work?

Ans. Chilling facilities, often called chiller plants, are centralized facilities that cool many structures. Chilled water systems use chilled water to remove heat from a building's interior.

Manufacturers & Suppliers of Cooling Tower & Chilling Plants

Company Name | Member Since |

|---|---|

Singhsons Refrigeration Mumbai, India | 23 Years |

B S Engineering Machinery Pvt. Ltd. Kolkata, India | 21 Years |

Drycool Systems India (P) Ltd. Noida, India | 21 Years |

Everest Composites Pvt. Ltd. Vadodara, India | 18 Years |

Shapet Induction Private Limited Rajkot, India | 16 Years |

Spectec Techno Projects Pvt. Ltd. New Delhi, India | 16 Years |

Rollabss Hi Tech Industries Kolkata, India | 15 Years |

Unique Air Products Vadodara, India | 15 Years |

Ved Engineering Noida, India | 12 Years |

Aeolus Sustainable Bioenergy Pvt. Ltd. Surat, India | 11 Years |

Popular Products