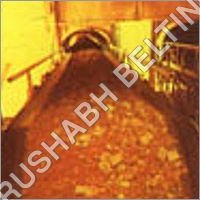

Powered by our 17 years of domain experience, we are offering premium quality Heat Resistant Conveyor Belt. It is manufactured using quality tested raw materials and pioneering technology in accordance with latest industry standards. This belt is highly demanded in major industries for conveyors. Offered belt helps in conveying heavy materials with ease. Also, this Heat Resistant Conveyor Belt can be availed from us in numerous lengths and thicknesses and at economical prices. Key Features: Slip resistance Perfect surface finish Hassle-free installation High tensile strength Physical property indexes: Item Class T1 T2 T3 T4 Test temperature 100C 125C 150C 175C Change range allowed Hardness Difference before and after aging (IRHD) 20 20 20 20 Maximum value after aging (IRHD) 85 85 85 85 Tensile Strength Change rate after aging (%) -25 -30 -40 -40 Minimum value after aging(Mpa) 12 10 5 5 Breaking Elongation Change rate after aging(%) -50 -50 -55 -55 Minimum value after aging(%) 200 200 180 180 The heat resistant belt include four types.Type I: it is able to resist the test temperature of no more than 100 oC, the max. short-time operating temperature is 150 oC, the symbol is T1.Type II: it is able to resist the test temperature of no more than 125 oC, the max. short-time operating temperature is 170 oC, the symbol is T2.Type III: it is able to resist the test temperature of no more than 150 oC, the max. short-time operating temperature is 200 oC, the symbol is T3.Type IV: it is able to resist the test temperature of no more than 175 oC, the max. short-time operating temperature is 230 oC, the symbol is T4.Selecting the right heat-resistant belt:The surface temperature depends on the material being carried. With large lumps (e.g. sintered ores, coke) which allow air to circulate, the belt surface should be cooler than the lumps.In the case of powdery or similar materials, such as cements, carbon black, etc., there is almost no temperature difference between material and belt surface. So when selecting a belt, its necessary to know temperature of the material carrying, surface temperature the can bear. More information pls find the following table.Kinds of Materials and Belt Surface Temperatures: Materials Carried Lump Size Temperature of Materials Carried Belt Surface Temperature Coke 100~200mm 70~100C 50~60C (4~8 inch) Cement Powder 100~250C 80~90C Clinker 10~30mm 100~220C 100~110C (0.4~1.2 inch) Moldings - 200~250C 80~90C Metal Powder - 170C 120~130C Raw Material below 30mm 180~220C 100~120C Sintered Ore (1.2 inch) *200~400C 150~300C 25~200mm (1~8 inch) Return of Sintered Ore below 10mm(0.4 inch) 260C 180~200C