Grinding & Milling Machinery

(8475 products)Automatic Flour Mill Capacity: 200-3000 Kg/Hr

330000 INR (Approx.)/Set

MOQ1 , Set/Sets

ColorBlue

Product TypeFlour Mill

TypeFlour Grinding Machine, Grain Processing Equipment

Capacity200-3000 Kg/hr

ComputerizedNo

AutomaticYes

Rapid Mixer Granulator - Capacity: 1500 Liter/Day

Price: 680000.00 INR/Sheet

MOQ1 Set/Sets

ColorOther

Product TypeRapid Mixer Granulator

TypeAbility to blend dry and wet granulation

General UseIndustrial

MaterialStainless Steel

ComputerizedYes

Nu Pharma Engineers & Consultant

Ahmedabad

Super Bonanza

Super Bonanza12 Years

Double Roll Crushers - Capacity: 350 T/Hr

Price Trend: 600000.00 - 6000000.00 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

Equipment TypeRoll Crusher

Product TypeDouble Roll Crusher

General UseIndustrial

ConditionNew

MaterialMetal

ACM Mill

Price: 1200000 INR/Set

MOQ1 Set/Sets

Sample AvailableYes

Main Domestic MarketAll India

Ultra Febtech Private Ltd.

Ahmedabad

4 Years

Super Premium

Super PremiumLab Colloid Mill - Stainless Steel Design , High-Efficiency Particle Size Reduction

Price: 80000 INR/Piece

MOQ1 Piece/Pieces

Supply Ability5 Per Month

Delivery Time2-10 Days

Chemech Engineering

Mumbai

21 Years

Jaw Crusher - Color: Yellow

MOQ1 Unit/Units

Product TypeJaw Crusher Machine

General UseIndustrial

ComputerizedNo

AutomaticYes

CNC Or NotNormal

Control SystemPLC Control

Siddharth Engineering Co.

Navi Mumbai

14 Years

Super Premium

Super PremiumIndustrial Maize Grinding Hammer Mill

Price: 500000 INR/Set

MOQ1 Ton/Tons

ColorBlack

Product TypeHammer Mill

General UseGrinding maize and other grains

MaterialOther, Mild Steel

TypeOther, Maize Grinding Mill

Capacity500-1000 Kg/hr

Mitsun Engineering

Vadodara

21 Years

Super Premium

Super PremiumDie & Mold Industry - Feature: High Efficiency

MOQ1 Unit/Units

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

AutomaticNo

Control SystemManual

FeatureHigh Efficiency

Precihole Machine Tools Pvt. Ltd.

Bhiwandi

Super Bonanza

Super Bonanza9 Years

Eco Friendly Amey Hammer Mill For Aluminum Copper Radiators Recycling

Price: 1100000 INR/Piece

MOQ1 Piece/Pieces

ColorOther, Gray

Product TypeAmey Hammer Mill For Aluminum Copper Radiators Recycling

General UseIndustry

MaterialCast Iron

TypeGear Grinding Machine

Control SystemManual

Amey Shredtech Private Limited

Thane

18 Years

Super Premium

Super PremiumCrusher Plant

Price Trend: 4000000.00 - 15000000.00 INR/Unit

MOQ1 Unit/Units

Product TypeStone Crushing Plant

Moderate Machines (pvt.) Ltd.

Jaipur

14 Years

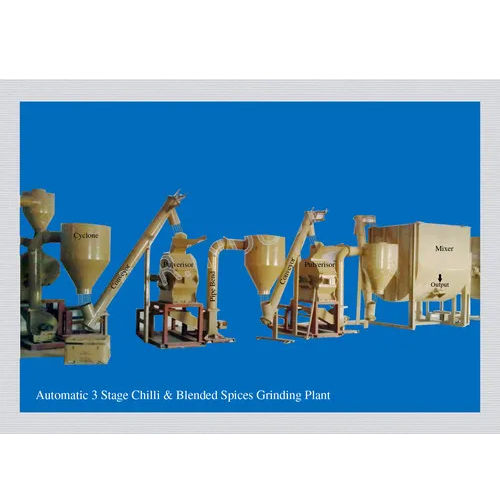

Spice Processing Plant - Feature: High Performance

Price: 2800000 INR/Set

MOQ1 Set/Sets

Product TypeSpice Processing Plant

General UseIndustrial

MaterialCast Iron

Control SystemPLC Control

FeatureHigh Performance, High Efficiency

B. R. Industries

Hyderabad

15 Years

Colloid Mill - Feature: High Performance

Price: 5000 INR/Unit

MOQ1 Unit/Units

ColorOther, Silver

Product TypeColloid Mill

General UseIndustrial

MaterialStainless Steel

Power5 Horsepower (HP)

Voltage220 Volt (v)

National Analytical Corporation

Mumbai

13 Years

High Efficiency Inline Colloid Mill

Price: 150000 INR/Unit

MOQ1 Unit/Units

ColorOther, Gray

Product TypeInline Colloid Mill

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

AutomaticYes

Innovative Engineering Works

Ahmedabad

Super Bonanza

Super Bonanza4 Years

Super Premium

Super PremiumSingle Phase Automatic Surface Grinding Machine

Price: 465000 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeAutomatic Surface Grinding Machine

General UseSurface Grinding

AutomaticYes

Emtex Machinery Private Limited

New Delhi

11 Years

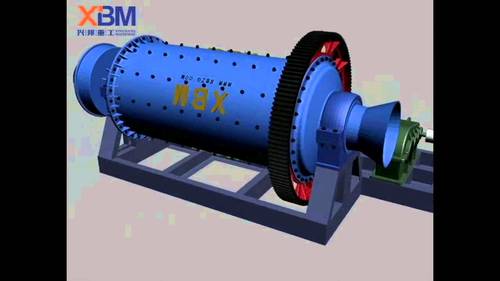

Autogenous Mill - Metal Construction, Long Service Life | High Performance, Automatic, Eco Friendly, Lower Energy Consumption

Price Trend: 100000.00 - 500000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeGrinding Machine

General UseIndustrial

MaterialStainless Steel

AutomaticYes

FeatureHigh Performance, ECO Friendly, Lower Energy Consumption

Berlin Machineries Private Limited

Pune

5 Years

Grinder With Motor 30 - Cast Iron, 500 Kg Capacity, Green | Automatic, 1-Year Warranty, Powerful & Quiet Motor System

Price: 1500000 INR/Unit

MOQ1 Plant/Plants

ColorGreen

Product TypeGrinder Machine

MaterialCast Iron

TypeFeed Grinding Machine

Capacity500 Kg

AutomaticYes

G S International

Khanna

5 Years

Plastic Scrap Grinder Machine - High-Quality Components and Materials | Cost-Effective and Internationally Compliant

Product DescriptionWe are highly renowned manufacturer and supplier of Plastic Scrap Grinder Machine in Ahmedabad, Gujarat, India. These machines are designed and fabricated using quality components and material to ensure that final output meets with international quality standards. Our offered machines are extensivel

Shreeji Metals

Ahmedabad

7 Years

Stainless Steel Jar Mill

Price Trend: 500000.00 - 5000000.00 INR/Unit

MOQ1 Unit/Units

Product TypeJar Mill

MaterialStainless Steel

AutomaticYes

Control SystemManual

Pratham Engineering

Mira Bhayandar

14 Years

Stainless Steel And Rust Proof Colloid Mill

Price: 5000000 INR/Piece

MOQ1 Piece/Pieces

ColorOther, Silver

Product TypeColloid Mill

MaterialStainless Steel

TypeFeed Grinding Machine, Gear Grinding Machine, Cylindrical Grinding Machine

Capacity150-1500 Kg/day

ComputerizedYes

Bombay Pharma Equipments Pvt. Ltd

Mumbai

4 Years

Swing Frame Grinder - High-Performance Steel | Precision Grinding, Durable Design, Ergonomic Handle

MOQ1 Unit/Units

Supply Ability15 Per Month

Delivery Time3 Week

Hardic Engineering

Ahmedabad

7 Years

Super Premium

Super PremiumGreen Upvc End Milling Machine

Price Trend: 300000.00 - 500000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeUPVC End Milling Machine

General UseIndustrial

Weight (kg)220 Kilograms (kg)

ComputerizedNo

AutomaticYes

FeatureECO Friendly, High Efficiency

Zenith Engineering And Equipments Private Limited

Vadodara

11 Years

Heavy Duty Crusher Machine For For Efficient Material Processing Capacity: 1.5-2 T/Hr

Price: 1500000 INR/Unit

MOQ1 Unit/Units

ColorOrange

Product TypeCrushing Machine

General UseCrushing And Shredding

Capacity1.5-2 T/hr

Weight (kg)1000-1200 Kilograms (kg)

FeatureHigh Performance

Jay Khodiyar Machine Tools

Rajkot

20 Years

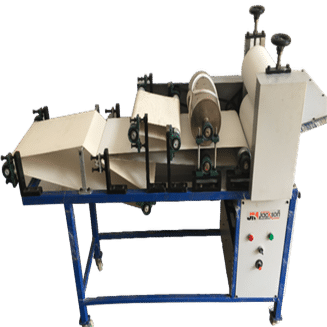

Jackson Semi Automatic Khakhra Machine 1 Hp Model Namenumber Kmm18, Power: 1 HP

Product DescriptionJackson Semi Automatic Khakhra Machine 1 Hp Model Namenumber Kmm18

Jackson Machine

Ahmedabad

7 Years

Super Premium

Super PremiumInstant Masala Grinders Capacity: 7-50 Kg/Hr

Price Trend: 72000.00 - 145000.00 INR/Set

MOQ1 Set/Sets

Capacity7-50 Kg/hr

Weight (kg)60-140 Kilograms (kg)

Dimension (L*W*H)40 x 60 x 70 Centimeter (cm)

Thirumalai Industries

Coimbatore

13 Years

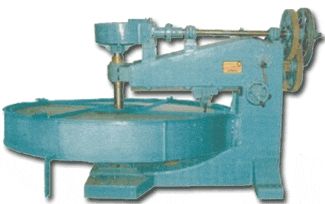

Sonar Stone Grinder Capacity: 8 To 16 Kg/Hr

Price Trend: 11500-20000 INR/Piece

MOQ20 , Piece/Pieces

Product TypeStone Grinder

General UseFOR DOMESTIC PURPOSE

MaterialStainless Steel

TypeFeed Grinding Machine

Capacity8 TO 16 Kg/hr

Weight (kg)26 Kilograms (kg)

Sonar Appliances Pvt. Ltd.

Delhi

7 Years

Colloid Mill

Price Trend: 50000.00 - 150000.00 INR/Unit

MOQ1 , Unit/Units

Supply Ability100 Per Month

Delivery Time1 Week

Jicon Technologies Private Limited

Mumbai

22 Years

Turmeric Impact Pulverizer

Price: 238500 INR/Unit

MOQ1 Unit/Units

Main Export Market(s)Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

CertificationsISO 9001

Jas Enterprise

Ahmedabad

21 Years

Synchronous Support-Grinding

Product DescriptionWe are a top exporter, manufacturer and supplier of Synchronous Support-Grinding. In Synchronous Support-Grinding, two opposing CBN grinding sheels simultaneously machine the same focal point on the workpiece from opposite sides. eliminating the axial forces generated in feed-in direction. The Synch

Weldor Engineering Pvt. Ltd.

Rajkot

4 Years

Commercial Spice Grinder Machine - Feature: High Performance

Price: 300000 INR/Unit

MOQ1 Unit/Units

Product TypeSpice Grinder Machine

General UseGrinder

MaterialStainless Steel

TypeFeed Grinding Machine

ComputerizedYes

AutomaticYes

Partik Trading Company

Howrah

3 Years

Latest From Grinding & Milling Machinery

Centerless Grinding Machine

By:

Industrial Machinery Corp.

Grinding & Milling Machinery

By:

Shreya Engineers

Grinding And Milling Machinery

By:

Techno Trade

Vertical And Horizontal Milling Machines

By:

Pao Fong Industry Co. Ltd.

Tool Cutter And Grinding Machines

By:

Rajkot Machine Tools

Manual Surface Grinding Machines

By:

G. K. Enterprises

Grinder

By:

Fixopan Machines Pvt. Ltd.

Surface Grinders

By:

Varun Machinery Store

Wet Grinders

By:

Eastern Gas Equipments

Tiles Grinding Machines

By:

Fine Engineering Works

Explore More Cities

Ready To Ship Grinding & Milling Machinery

Grinding & Milling Machinery

Two typical machining operations in the manufacturing sector are milling and grinding. Both of these processes require the removal of material from a workpiece, and they are both capable of working with a broad range of materials. Milling and grinding are two processes that may be used to modify a workpiece no matter what kind of metal or alloy it is made of. This holds true regardless of whether the piece is composed of iron, aluminium, steel, copper, or any other material. However, grinding and milling are not interchangeable terms. Remove material from a workpiece, each of these processes operates uniquely.

Introduction To Grinding & Milling Machinery

A grinding machine, more often referred to simply as a grinder, is a kind of machine tool or power tool that is used for grinding. Machining that employs the use of an abrasive wheel as the primary cutting tool is referred to as abrasive wheel milling. Through a process known as shear deformation, each grain of abrasive that makes up the wheel's surface removes a microscopic chip from the material being worked on.

Difference Between Machining And Grinding

Machining: Machining is generally used for removing large amounts of material (high MRR). Additionally, it has the ability to semi-finish the surfaces. The level of dimensional precision and tolerance that can be attained with these procedures is subpar. It is very challenging to achieve a tolerance of fewer than 2 micrometres. For the purpose of material removal, it makes use of a cutting instrument (also known as a cutter). The most frequent material used in the construction of this cutting tool is metal; however, cutters composed of ceramic, diamond, and cBN are also commercially available. Every cutter has its own unique geometry. This indicates that numerous characteristics, such as angles in various directions, orientations of various planes, the radius of the nose and various edges, etc., are clearly defined. A cutter may have either a positive or a negative rake angle. The value may fluctuate anywhere from 15 degrees in each direction. There is no way for the cutter's clearance angle to be zero or negative. The range of its value is often between +3 degrees and +15 degrees. During machining, each and every cutting edge of the cutter contributes in an equal and equal capacity to the cutting action. During the procedure, shearing is the primary action that takes place. Consumption of specific energy (measured in terms of electricity demanded per unit MRR) is rather low. Only a very small part of the heat created by cutting is absorbed by the work material (between 70 and 80 per cent of the heat is transported away by the moving chips). These techniques are unable to provide a smooth surface finish on hardened materials, as well as materials that are intrinsically highly brittle and tough.

Grinding: This process is usually used for polishing the surface of something. It results in a low MRR. Grinding provides improved dimensional precision as well as a narrow tolerance. It is not difficult to realise a tolerance of 0.5 micrometres or less. The substance is removed with the use of a grinding wheel. The wheel is constructed up of very small, sharp abrasives (such as alumina, silica, and so on) that have been bonded in another medium. Abrasive particles have unpredictable characteristics, despite the fact that the grinding wheel has predefined specifications. Because of this, the angles, orientation, and radius of abrasives, among other characteristics, are not determined. Abrasives have sharp rake angles that may range from plus 60 degrees to minus 60 degrees and even farther than that. Abrasive materials have clearance angles that are sharp as well. It is also possible for it to be negative or zero. Only a small fraction (less than one per cent) of the abrasives that are present on the wheel's perimeter really contribute to the cutting action. The grinding process involves a variety of other operations as well, including rubbing, scraping, ploughing, and shearing. The high specific energy consumption may be attributed to the significant amount of energy that is lost as a result of rubbing, ploughing, and scratching. A significant portion of the heat produced is absorbed by the working material, which results in severe thermal damage to the surface that has been completed. The work material's hardness, ductility, and toughness typically do not provide any difficulties while grinding.

Applications of Grinding & Milling Machinery

For the purpose of grinding various work parts, a sort of instrument known as the grinding machine is employed. The abrasive wheel serves as the primary cutting tool in this system. The abrasive wheel has a rough surface that rips off tiny pieces of the work item in accordance with the specifications. It is also referred to as a grinder in certain circles.

It consists of a bed that has a guide that is set in place to hold the workpiece, as well as a wheel that is power-driven and rotates at a speed that has been specified in advance. The head of the grinder may be positioned to move over a piece of work that is held in place, or the piece of work can be moved while the head of the grinder stays in its current location. A hand wheel or a computerised numeric controller may be used to provide fine-grained control over the position of the table or the grinding head, respectively.

It produces a significant amount of heat, which is why coolants are used to lower the temperature of the workpiece in order to prevent it from overheating, hence avoiding accidents and keeping its tolerance level stable. Because the finishing operations in certain high-precision grinding machines, such as hydraulic cylindrical grinders and surface grinders, create very little heat, coolants are not required because the temperature is manageable.

Types of Grinding & Milling Machinery

Grinders have a variety of applications, including those in the engineering, electrical, automotive, and other sectors. The following is a list of the numerous types of this equipment:

- To accomplish roughing and finishing tasks, a bench grinder is often handled by hand and typically consists of two wheels of varying grain sizes that are set on a floor stand or workbench. Tool bits, as well as other types of tool fabrication and maintenance, are the primary applications for this material.

- Coated abrasives are used in the machining process that is a part of a belt grinder. This procedure grinds many materials, including metals. Belt grinding is a flexible operation that may be used for a variety of purposes, including stock removal and surface finishing, among others.

- Finishing jigs dies, and fittings often requires the use of a jig grinder. It may also be used for grinding difficult surfaces and finishing work. Additionally, it can be used to grind holes. During the production of high-precision gears, a gear grinder is the tool of choice for removing the last few inches of material.

- One kind of cylindrical grinder has a centre, while the other lacks a centre entirely. Cylindrical grinders come in both varieties. There may be more than one grinding wheel attached to a cylindrical grinding machine. In this step, the workpiece is rotated before being put through the wheels, which results in the formation of a cylinder. It finds widespread use in the production of dimensionally correct items like tubes, rods, bushings, bearings, and other components, among other things.

- An effective surface grinder may either be handled manually or by a computer numerically controlled machine. It features a head that may be lowered while the work item is moving back and forth across a table, passing the wheel in between each movement. Both the tool and cutter grinder and the D-bit grinder are capable of performing the duties of a drill bit grinder in addition to other specialised tool room tasks.

FAQs: Grinding & Milling Machinery

Q. What is a grinding and milling machine?

Ans. Mills are devices that reduce the size of solid materials by grinding, crushing, or cutting them into smaller bits. Mills may take the form of structures, machines, or even household appliances. Comminution of this kind is an essential step in a lot of different procedures.

Q. What are grinding and milling machines used for?

Ans. In most cases, the offered materials will be properly shaped and finished with a high-quality surface that has minimal surface roughness with the assistance of a grinder. First and foremost, it is a finishing procedure that involves the removal of very tiny amounts of metal in order to produce extremely exact results.

Q. What are the types of grinding?

Ans. Some of the different types of grinding methods are:

- Thread grinding.

- Gear grinding.

- Contour grinding.

- Centerless grinding.

- Internal grinding.

- Cylindrical grinding.

- Surface grinding.

Q. What is the process of grinding and milling?

Ans. Milling and grinding are two distinct processes, despite the fact that they both require the elimination of material from the surface of a workpiece. The first method of machining, known as milling, is distinguished from the second method, known as grinding, by the fact that the former makes use of a milling machine while the latter makes use of a grinding wheel.

Manufacturers & Suppliers of Grinding & Milling Machinery

Company Name | Member Since |

|---|---|

Jicon Technologies Private Limited Mumbai, India | 22 Years |

Chemech Engineering Mumbai, India | 21 Years |

Mitsun Engineering Vadodara, India | 21 Years |

Jas Enterprise Ahmedabad, India | 21 Years |

Jay Khodiyar Machine Tools Rajkot, India | 20 Years |

Amey Shredtech Private Limited Thane, India | 18 Years |

Ecoman Vadodara, India | 15 Years |

B. R. Industries Hyderabad, India | 15 Years |

Siddharth Engineering Co. Navi Mumbai, India | 14 Years |

Moderate Machines (Pvt.) Ltd. Jaipur, India | 14 Years |

Popular Products