High Grade Slag Pot By Chaeng

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Product Type | Cast Equipment |

| Material | Stainless Steel |

| Surface Finishing | Casting |

| Weight | 1-120T Kilograms (kg) |

| FOB Port | any port |

| Payment Terms | Others |

| Supply Ability | 10000 Per Year |

| Delivery Time | according to your need Months |

| Sample Policy | Free samples are available |

| Packaging Details | according to your need |

| Main Export Market(s) | Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America |

| Main Domestic Market | All India |

| Certifications | ISO9001: 2015 |

Product Overview

Key Features

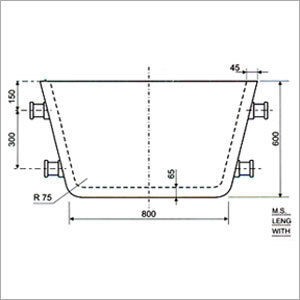

Weight :1-150T

Material :ZG230-450, ZG270-500, ZG310-570, ZG340-640 and so on

Application :Metallurgy, chemical industry

Customizable :Yes, based on user's drawings

Shape: Every Shape

Suited for a number of processes, such as lead, aluminium, iron, steel, chrome, manganese, copper and other smelting applications.

Why almost 2000 enterprises choose CHAENG?

1. Mittal orders over 100 CHAENG slag pots annually

Large steel plant of the world - Mittal Group purchases CHAENG slag pot every year since 2008. The order amount has been over 100 pieces / year by now. At present, CHENG has become a long-term strategic partner of Mittal Steel Group.

2. Longer service life, 6000 usage times

The slag pots in the market can be used 450-600 times generally, while CHAENG slag pot can ensure 6000 times of usage frequency; and the first maintenance time is 2-3 months later than peers. The long service life of CHAENG slag pot greatly reduce the maintenance cost of users.

3. Advanced Level-2 Flaw Detection Standard

The uses advanced detection equipment to perform nondestructive testing on each slag pot, to ensure the internal quality of slag pot. The key parts can reach level-2 testing standards of GB7233-2007, and CHAENG can customize the process according to the customer's specific testing standards.

4. Exported to 50 countries and areas

The customizes slag pots according to customer drawings, obtaining market reputation with high-precision technology. CHAENG slag pots have been successfully exported to the United States, Mexico, Brazil, India, South Korea, Japan, Russia, more than 50 countries and regions.

Processing advantages

Rich experience and reliable quality

It is experienced and specialized in customizing various types of slag pots, with advanced casting equipment, first-class machining and flaw detecting technology. CHAENG has sucessfully cooperated with Shanghai Baosteel, Mittal Group, TaTa Group.

International quality certification

It has passed the ISO9001: 2015 international quality certification. CHAENG slag pot production follows international standards to effectively ensure the quality. Moreover, the annual production capacity of 25 thousand tons of CHAENG provides guarantee for the delivery date.

Professional casting team, customized solutions

Before production, CHAENG communicates fully with customers to make specific production plan of slag pot; strictly control every procedure of mold, modelling, casting and testing for the pursuit of 100% quality; regularly train the front-line operatives, to ensure stable production quality of slag pots / slag ladles.

Process

slag pot process

The first step: simulation, modeling

Before casting, numerically simulate the casting process by CAE software to analyze the molding process, predict and optimize the product quality.

The second step: pouring, heat treatment

Perform the spectral analysis on the sample of hot metal. After qualified, start pouring according to the principle of "low temperature and quick casting", and the pouring time and temperature shall be recorded.

The third step: finishing, flaw detection

The uses advanced detection equipment for non-destructive testing to ensure the internal quality of slag pot. The steel castings can meet level-two flaw detection standards.

Case

Slag pot is the main product of CHAENG, more than 95% of CHAENG slag pots and ladles are exported abroad, such as the United States, Canada, Mexico, Brazil, Germany, Turkey, India, Korea, Japan.

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

2000

Establishment

1958

Working Days

Monday To Sunday

Related Products

Seller Details

Zhengzhou, Henan

Mr Tony

Address

Mengzhuang Town, Huixian City, Zhengzhou, Henan, China

slag pot in Zhengzhou

Report incorrect details