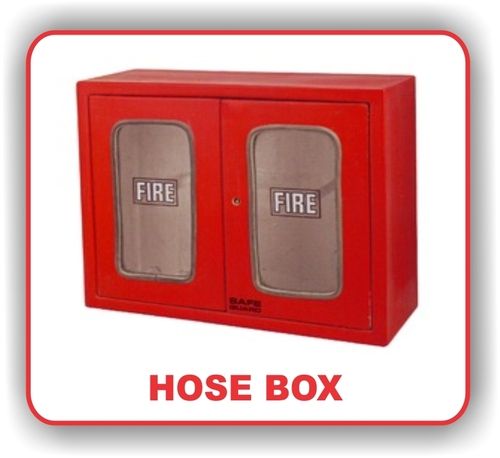

Hydrant Valve Avail from us, a variegated range of Hydrant Valves, which is specifically designed to suit the requirements detailed by the clients. Using superior quality raw material, we fabricate these valves as per ISI and Indian standard IS:5290. Furthermore, our valves also satisfy the requirements detailed by other agencies such as MMD (Mercantile Marine Dept). 1. Oblique Type Hydrant Valves: Item Description : 63mm Single outlet Landing Valve as per IS:5290 Type A, ISI Marked, having 75mm NB inlet & 63mm Female Inst. OutletRef. Standard : IS:5290 Type A Material of construction: Gunmetal IS 318 LTB2/ SS304/ SS316 (or as per client specification)Inlet : Flanged (as per client requirement)Outlet : Generally Female instantaneous (Male Inst. Outlet available on request)Size : 38mm to 63mm 2. Double Control Type Hydrant Valves: Item Description: 63mm Double controlled Hydrant Valve, 100mm NB Inlet &63mm, 2 nos. Female Inst. outlet as per IS:5290 Type BRef. Standard: IS:5290 Type BSize : 38mm to 63mm 3. Right Angle Type Hydrant Valves: Item Description : 63mm Fire Hydrant Valve Right Angle, having 63mm NB inlet & 63mm Female Inst. OutletRef. Standard : BS:336Material of construction : Gunmetal IS:318 LTB2/ SS304/ SS316 (or as per client specification)Inlet : Flanged (as per client requirement)Outlet : Generally Female Instantaneous (Male Inst. Outlet available on request)Size : 38mm to 63mm HYDRANT SYSTEM We offer a range of FIRE HYDRANT SYSTEM and YARD HYDRANTS with all required accessories. Some of the feature of this systems are as follows - HYDRANT SYSTEM The Hydrant System comprises of AC motor driven pump sets with all required accessories including valves, instrumentation and controls etc. Complete in all respects. An automatic hydrant system is furnished covering the areas completely from independent. Pipe work from the fire water pump set. The hydrant pipe work is remaining pressurized through the proposed jockey pump taking care of any leakages in the system pipe lines, valves and fittings. The hydrant system is kept charged by pressurized water at approx. 7 Kg. Cm. Sq. at all times. In the event of fire when any of the hydrant valves in the net work is opened,the resultant fall in pressure system is enabling starting the AC MOTOR driven fire water pumping set through pressure switches automatically. One diesel engine pump shall be standby pump serving hydrant system. Apart from the automatic starting of the pump sets,provision shall be kept for manual starting also. Shutting down of the pump sets shall be manual. YARD HYDRANTS Hydrants inside the building is furnished with required accessories such as hose pipes with instantaneous gun metal couplings and g.m branch pipes located in hose cabinets. The hose cabinets is wall / column mounting type, constructed out of 18 gauge mild steel sheets. The internal hydrants ( Landing valves) is single headed type taken out from 150/100 mm dia riser through suitable reducer. The outlets is gun metal and confirm to IS : 5290. HT Hose reels is firmly held against the wall by suitable heavy brackets and supports. The hose reel is swinging type ( 180 deg.) and the entire Dum reel etc. is as per IS : 3876. The rubber tubing is best quality ( Dunlop ) and the nozzle is 6 mm dia. Shut off type. The equipment shall be out of one of the approved makes The hydrant main is laid in the form of ring main. The hydrant risers is terminated with air release valves at the highest points to release the trapped air in the pipe work.