Material Handling Equipment

(11158 products)Product Showcase

Material Handling Machinery - Attributes: Strong

MOQ1 Unit/Units

UsageIndustrial

ConditionNew

Lifting Capacity500 - 1000 Kilograms (kg)

Power SourceHydraulic

FeatureDurable

Warranty1-2 Years

Action Construction Equipment Ltd.

Faridabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller10 Years

Durable Steel W Strap

MOQ1 Unit/Units

ColorSilver

SizeDifferent Size

Product TypeSteel W Strap

UsageIndustrial

Equipment TypeSteel W Strap

ConditionNew

Semi-Automatic Tile Adhesive Production Lines

Price: 1750000 INR/Unit

MOQ1 Unit/Units

Weight6000-7000 Kilograms (kg)

UsageIndustrial

Equipment TypeTile Adhesive Production Lines

ConditionNew

Automatic GradeSemi-Automatic

Drive TypeElectric

Sigma Instrumentation

Ahmedabad

Trusted Seller

Trusted Seller15 Years

Super Premium

Super Premium220-415 Voltage High Strength Mild Steel Automatic Palletizer

Price: 135000 INR/Unit

MOQ1 Piece/Pieces

Usageindustrial

ColorWhite and Blue

Product Typehttps://tiimg.tistatic.com/fp/1/006/478/mild-steel-automatic-palletizer-793.jpg

Equipment TypeMild Steel Automatic Palletizer

ConditionNew

Lifting Capacity100-150 Kilograms (kg)

Industrial Feeder - Attributes: Durable

Price: 500000.00 INR/Unit

MOQ1 Unit/Units

Width600 - 2000 Millimeter (mm)

Length1500 - 3000 Millimeter (mm)

Equipment TypeFeeder

ConditionNew

Power SourceElectric

WarrantyStandard

Ecoman

Vadodara

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller15 Years

Yellow-Black Battery Operated Hydraulic Stacker

Price: 485000 INR/Piece

MOQ1 Piece/Pieces

Product TypeBattery Operated Hydraulic Stacker

ColorYellow-Black

UsageIndustrial

Equipment TypeFork Stacker

ConditionNew

Max. Lifting Height1 Meter (m)

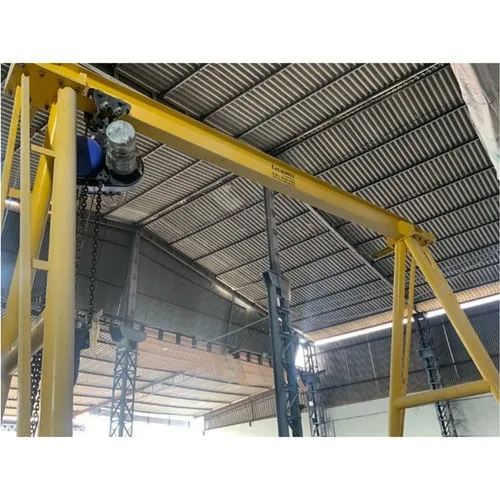

Durable Portable Gantry Crane Manual Chain Pulley Block

Price: 150000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

Product TypePortable Gantry Crane Manual Chain Pulley Block

ColorYellow

Equipment TypePortable Gantry Crane Manual Chain Pulley Block

ConditionNew

Power SourceElectric

Stainless Steel Electric Permanent Magnetic Lifter

Price: 13000 INR/Piece

MOQ100 Piece/Pieces

Product TypeStainless Steel Permanent Magnetic Lifter

ColorYellow and Black

Equipment TypeStainless Steel Permanent Magnetic Lifter

ConditionNew

FeatureHigh Design

AttributesStrong, Durable, Easy To Operate, Rust Proof, Flame Proof

Magna Tronix

Chennai

Trusted Seller

Trusted Seller4 Years

Super Seller

Super SellerIndustrial Goods Lifts - Color: Yellow

Price: 350000 INR/Unit

MOQ1 Unit/Units

ColorYellow

UsageIndustrial

ConditionNew

Power SourceElectric

Warranty1 Year

Starline Cranes Private Limited

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller6 Years

Scissor Lift Self Propelled Battery Operated - Attributes: Durable

Price: 1795000 INR/Piece

MOQ1 Piece/Pieces

Width7 Foot (ft)

UsageIndustrial

ColorYellow

Product TypeScissor Lift Self Propelled Battery Operated

Height4*14 Millimeter (mm)

Equipment TypeScissor Lift Self Propelled Battery Operated

Vedant Lift

Pune

Trusted Seller

Trusted Seller2 Years

Super Premium

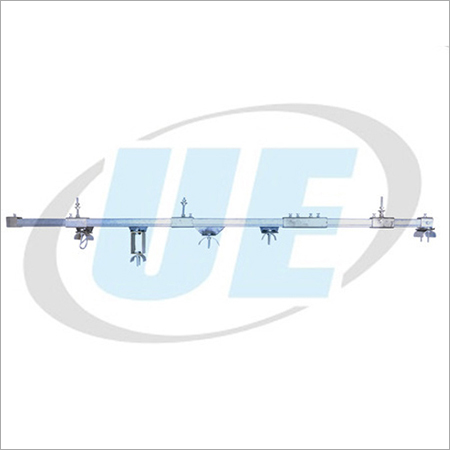

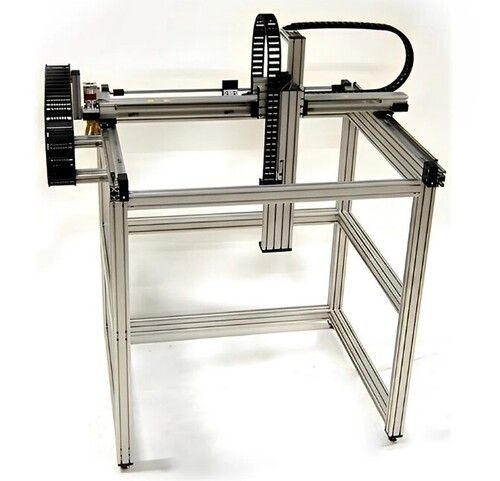

Super PremiumStainless Steel Cable Carrier - Color: Sliver

Price Trend: 1000.00 - 10000.00 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

ColorSliver

ConditionNew

Power SourceManual

Utkal Engineers

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller17 Years

Strong Industrial Rotary Feeder

Price: 450000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

Equipment TypeRotary Feeder

ConditionNew

AttributesStrong, Durable, Easy To Operate

Rust Proof Self Propelled Boom Lift

Price: 5000000.00 INR/Piece

MOQ1 Piece/Pieces

Height25-59 Foot (ft)

ColorYellow

Equipment TypeSelf Propelled Boom Lift

ConditionNew

Power SourceDiesel

AttributesStrong, Rust Proof, Durable, Easy To Operate

Dynamic Crane Engineers Private Limited

Pune

Circular Electromagnetic Lifter Application: Industrial

Price: 65000 INR/Unit

MOQ1 Unit/Units

Voltage220 - 440 Volt (v)

ApplicationIndustrial

Power SupplyElectric

Product TypeMagnets

ShapeRound

Linux Magnetics

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller7 Years

Industrial Trough

Price: 8220 INR/Piece

MOQ10 Number

Supply Ability200 Per Month

Delivery Time2-3 Days

Plastocon Industries Private Limited

Ankleshwar

Hydraulic Hand Pallet Truck - Yellow Color, 1-3 Ton Lifting Capacity | Ideal for Industrial Use

Price: 14500 INR/Unit

ColorYellow

Product TypeHydraulic Hand Pallet Truck

UsageIndustrial

Lifting Capacity1-3 Metric Ton

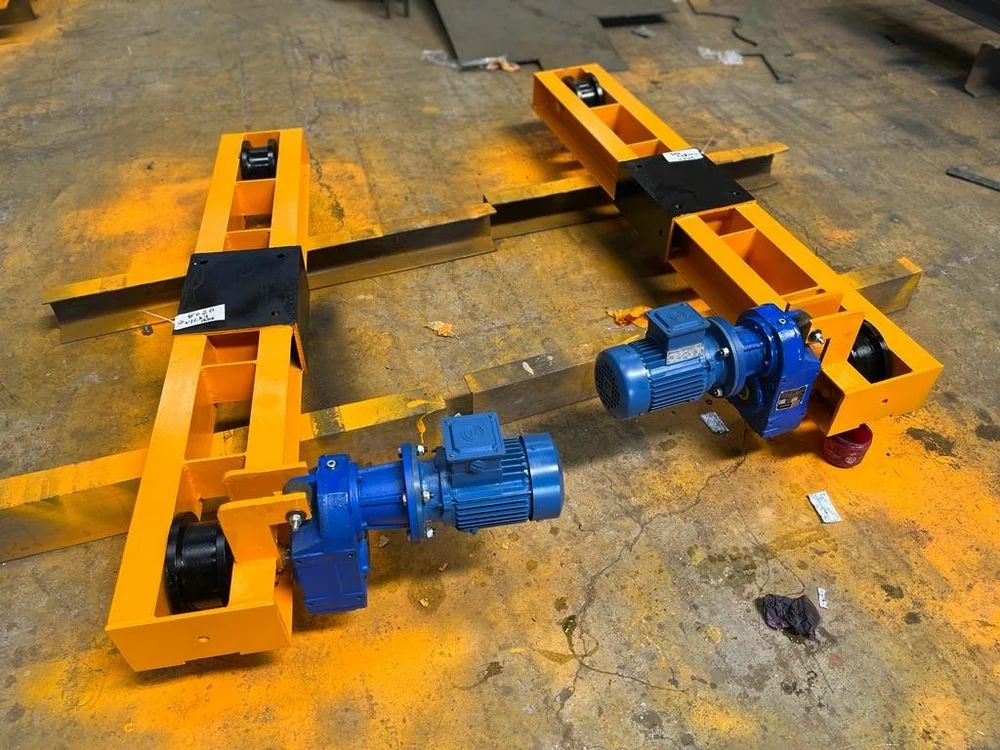

Motorized Trolley For Chain Pulley Block

Product DescriptionFEATURES :\015\012* REQUIRE LESS SPACE.\015\012* EASY INSTALLATION.\015\012* EQUIPPED WITH AL SAFETY FEATURES.\015\012* ECONOMICAL.\015\012* DESIGNED AS REQUIRED.\015\012* LESS POWER CONSUMPTION.\015\012* NO ATTENDANT REQUIRED.\015\012* EASY HANDLING.\015\012* USER FRIENDLY

Standard Hydraulic Pallet Truck - Attributes: Strong

Price: 20000 INR/Piece

MOQ1 Piece/Pieces

Product TypeHydraulic Pallet Truck

UsageFor Lifting

ColorYellow

Width550 Millimeter (mm)

Equipment TypeTruck

ConditionNew

Amratlal Chhaganlal

Mumbai

Trusted Seller

Trusted Seller17 Years

Super Premium

Super PremiumDsl Current Collector - Lifting Capacity: 10 Metric Ton

Price: 900 INR/Number

MOQ4 Piece/Pieces

Equipment TypeCURRENT COLLECTOR

ConditionNew

Lifting Capacity10 Metric Ton

Max. Lifting Load10 Metric Ton

Max. Lifting Height10 Meter (m)

Power SourceElectric

Gunatit Electropower Private Limited

Rajkot

Trusted Seller

Trusted Seller13 Years

Super Premium

Super PremiumIndustrial Material Handling Systems - 2 to 3 Ton/hour Capacity, 7 Feet Maximum Lifting Height | Strong and Durable Design with 12-Month Warranty

Price: 900000 INR/Piece

MOQ1 Piece/Pieces

Product TypeMaterial Handling Systems

ConditionNew

Lifting Capacity2 to 3 ton/hour Tonne

Max. Lifting Height7 Meter (m)

Power SourceOther, Mechanical

Warranty12 months

Parul Engineering Private Limited

Pune

Trusted Seller

Trusted Seller3 Years

Super Premium

Super PremiumHigh Speed Stacker Conveyor - Color: White

Price: 80000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

SizeStandard

Product TypeHIGH SPEED STACKER CONVEYOR

ColorWhite

ConditionNew

Power SourceElectric

Industrial Weigh Feeder Machine - Color: Blue

Price: 300100.00 INR/Set

MOQ1 Set/Sets, Set/Sets, Set/Sets

UsageIndustrial

ColorBlue

Equipment TypeWeigh Feeder

ConditionNew

FeatureStrong, Durable

Warranty12 Months

Esskay Weighing And Automation

Bengaluru

Super Seller

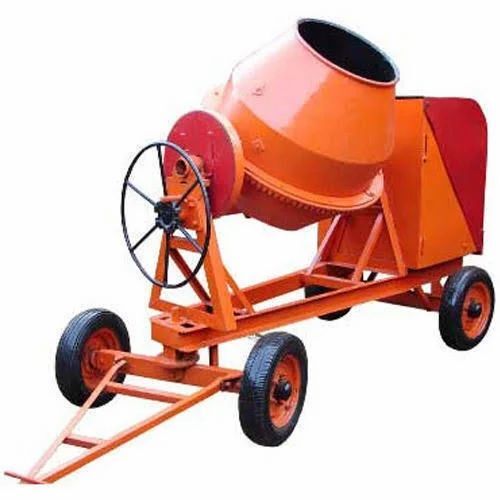

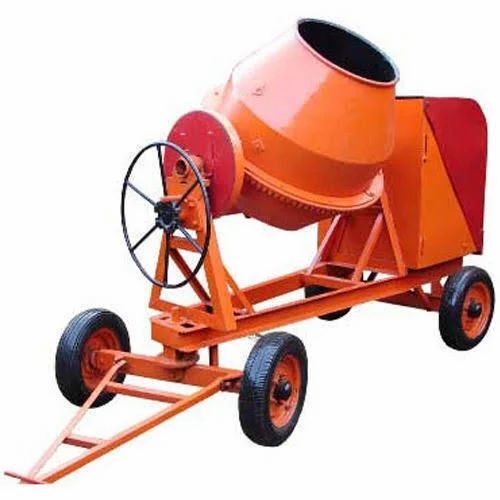

Super SellerBuilder Hoist - Attributes: Durable

MOQ1 Piece/Pieces

SizeStandard

ColorOrange

UsageIndustrial

ConditionNew

Power SourceElectric

Warranty1 Year

Everest Equipments Private Limited

Kolkata

Trusted Seller

Trusted Seller13 Years

Super Seller

Super SellerEasy To Operate Dsl System

Price Trend: 100000.00 - 150000.00 INR/Piece

MOQ1 , Piece/Pieces

Equipment TypeDSL System

ConditionNew

Power SourceManual

FeatureEasy To Operate

WarrantyYes

AttributesStrong, Durable, Consume Less Power, Rust Proof, Flame Proof, Easy To Operate

Max Industries

Kapadwanj

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller18 Years

Strong Fly Ash Bulker Unloading System

Price: 553000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

Equipment TypeFly Ash Unloading System

ConditionNew

Lifting Capacity20-25 Tonne

Power Consumption80 Horsepower (HP)

FeatureStrong, Durable

Air Vac Equipment

Ahmedabad

Trusted Seller

Trusted Seller18 Years

Super Seller

Super SellerRotating Platform Car Scissor Lift - Attributes: Easy To Operate

Price: 750000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

ColorOrange

ConditionNew

Power SourceHydraulic

Warranty1 Year

AttributesStrong, Easy To Operate

Hydro Fabs

Bengaluru

Trusted Seller

Trusted Seller3 Years

Premium Seller

Premium SellerWire Rope Hoist 1 Ton

Price: 60000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability5 Per Week

Delivery Time1 Week

Ganesh Engineering Co.

Ahmedabad

Trusted Seller

Trusted Seller19 Years

Super Seller

Super SellerMagnetic Lifter - Neodymium Magnetic, 140mm Wide x 170mm Long x 25mm High, Yellow | Lightweight, Compact Design, No Power Requirement, Excellent Safety Features, High Lifting Capacity

Price: 15000 INR/Piece

MOQ1 Piece/Pieces

UsageIt is use for lifting object

Product TypeMagnetic Lifter

ColorYellow

Equipment TypeMagnetic Lifter

ConditionNew

Power SourceElectric

Excel Magnetics

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller17 Years

Latest From Material Handling Equipment

Explore More Cities

Ready To Ship Material Handling Equipment

Material Handling Equipment: Most Efficient Way to Deal With Heavy Problems

Material handling equipment is any machine, tool, or equipment that is employed in the industrial sector for moving, loading, or storing heavy loads. They are most commonly used in commercial environments and in some industries, without these equipment, the operations will come to a halt. The majority of the material handling equipment is designed to be automatically operated such as forklifts, hydraulic pallet trucks, etc. helping operators to lift and transport tons of materials swiftly and safely.

Industrial Benefits of Working With Material Handling Equipment

Material handling equipment has numerous benefits for fast forwarding internal operations:

Saving Money

Irrespective of the nature of the industry, cutting expenses and saving money is the priority. Although Material handling equipment requires a notable investment, it will prove to be a great money saver in the long term. Employing them in the facility will save you a lot of time and money on internal operations such as loading, unloading, moving, and storing heavy loads.

Further, this equipment will allow you to reduce the number of workforces that you need before moving or transporting heavy loads, saving labor expenses.

Saving Space

Having adequate space is a must in an industrial facility for streamlining production, staff movement and transportation goods, etc. Using storage and material handling equipment a single employee can make a lot of room by moving heavy loads, final products waiting to be moved but are on hold, frequently.

Furthermore, material handling equipment that can lift loads or pallets to certain heights can make the job easier. They can store pallets on shelves at heights, cleaning up the floor space for other operations.

Reducing Damage

Unlike manual loading or moving methods, material handling equipment eliminates the chances of accidental product damage. Assigning the moving tasks of heavy loads to facility staff manually can result in accidental drops or destruction of the product, making the company liable to pay for damages. Here’s when a company should employ material handling equipment, letting a single operator move all loads around the facility. So that others can focus on different essential tasks.

Reliable Customer Service

Saving more time while delivering and shipping the products allows a business to focus more on its customers. Hence, facilitating material handling equipment in your facility will allow your personnel to offer reliable customer services. Moreover, client satisfaction hits when bulk orders are delivered within promised timelines.

Increased Efficiency and Productivity

To overthrow your competitors, it is highly essential for a business to stay competitive. It always requires high efficiency and productivity levels to stay ahead of your market competitors. One way to do it is by streamlining your operations and logistics by facilitating material handling equipment. They are one of the most logical and cost-effective solutions for increasing the productivity levels of your staff by automating operations. Mainly the productivity index blows up the charts when material handling equipment overtakes manual work. Because manual labor work results in high fatigue levels, which decreases productivity.

Increased Safety

Material handling equipment automates the complete labor work. Hence, it eliminates the chances of having injuries and accidents on the facility floor, which earlier happened because of human error. It's not easy to manually move or transport heavy loads weighing up to hundreds of kilos. It makes the facility prone to various types of accidents and even catastrophic events. For instance, in the construction, mining, and manufacturing industries, operations can easily go wrong without the help of material-handling equipment.

Employee Satisfaction

In many places across industries discomfort in jobs caused by manual work demotes the employees to the extent that they have only one option, which is to leave the job. By hiring automatic industrial instruments like material handling equipment, employees get motivated to put effort into their work and show productivity levels.

Four Major Types of Material Handling Equipment

Material handling equipment are classified into four major categories, which are: storage and handling, bulk material, industrial trucks, and automated systems. Let’s discuss about them in detail to help you choose the one right for you:

Storage Material Handling Equipment

These types of material-handling equipment are employed in storage sections and material-handling units. These equipment safely store the materials or goods for a short period that are not being used presently.

These equipment include:

- Pallet Trucks: it is a trolley on wheels that lifts and transports palletized loads.

- Shelves & Drawers: these are utilized to store small to medium-sized materials.

- Mezzanines: these are unique platforms developed using wood, steel, or fiberglass, to be used as additional storage floors.

- Stacking frames: special equipment used to store a large number of pallets or racks.

Bulk Material Handling Equipment

Various types of materials in loose form are stored and transported using bulk material handling equipment. Types of loose materials include nuts, bolts, metals, minerals such as rocks and stones, liquids, etc.

These equipment include:

- Conveyor Belts: these are interlinked belts driven by pulleys to transport materials between different stations of the facility.

- Stackers: this equipment is used to load or unload heavy materials with minimum manual work for storage.

- Reclaimers: these are used to separate specific material from stockpiles.

- Bucket elevators: these are employed to lift bulk materials on a large scale.

- Hoppers: specially designed to dump the loose materials in containers or any storing medium.

Industrial Truck Equipment

For large-scale moving operations, Industrial trucks of various types are used to automate the complete process. They are highly efficient in loading, unloading, and moving heavy objects within the facility. These industrial trucks are classified based on their object lifting methods for instance some come equipped with a fork, a few with flat surfaces, and some require additional equipment support for lifting.

- Forklifts: these are industrial trucks, equipped with forks, utilized for lifting and moving heavy objects.

- Hand trucks: these unique equipment are pushed by hands, equipped with two wheels and one ledge to carry objects around.

- Pallet Trucks: these are hand-driven material handling equipment, designed to lift and move the palletized loads around the facility.

- Sideloaders: these are specially designed to carry out material handling and lifting in narrow aisles and passageways.

- Order Pickers: these are very unique equipment, using which an operator is lifted to reach the materials stored on high shelves.

Automated Systems

Automated Systems or Engineered Systems, as the name hints, are modern-age automatic equipment streamlining material handling and lifting on a large scale. These are high-powered vehicles that function with a combination of software and robotics.

These equipment include:

- Autonomous Mobile Robots or AMRs: these are advanced robots with flat surfaces working independently to analyze the environment and move objects without any human intervention.

- Automated Storage and Retrieval Systems or AS/RS: most commonly employed in warehouses and large distribution centers to automate the process of moving objects and managing stock. They receive instructions from the computer and once set, they work independently.

- Automated Guided Vehicles or AGVs: these equipment are a combination of software and robotics, but require human operators to navigate through the facility.

Applications of Material Handling Equipment across Various Industries

Different industries hire different types of material-handling equipment for various applications. Here are a few major industries that utilize them:

- Construction: The construction industry extensively utilizes material handling equipment, especially forklifts and hand pallet trucks, to move heavy objects like cement bags, drums, etc. around the construction site.

- Distribution Centers: Material handling equipment like stackers and engineered systems like AGVS are employed in distribution centers to move and load final products toward transportation units, either to store or for delivery.

- Warehouses: These equipment are hired in warehouses to load, unlock, or move objects within the facility. For higher productivity levels they mostly use pallet trucks and stackers.

- Manufacturing Plants: Manufacturing plants use both manual and automated material handling equipment on a large scale. They are conveniently utilized to transport heavy loads or machinery from one station to another.

How to Choose The Right Material Handling Equipment For Yourself?

These are the important factors to consider before choosing the equipment for yourself:

- Type of Material: identify which type of material you are hiring for such as solids, liquids, or gases.

- Work Space: identify how much work space your facility has to accommodate material handling equipment. For confined spaces, heavy-duty machines cannot be equipped.

- Budget: must choose affordable equipment to use the resources efficiently.

- Cost Effective: companies must hire material handling equipment that offers low operational and maintenance costs.

Manufacturers & Suppliers of Material Handling Equipment

Company Name | Member Since |

|---|---|

Ganesh Engineering Co. Ahmedabad, India | 19 Years |

Durapak Chennai, India | 18 Years |

Max Industries Kapadwanj, India | 18 Years |

Air Vac Equipment Ahmedabad, India | 18 Years |

Utkal Engineers Ahmedabad, India | 17 Years |

Amratlal Chhaganlal Mumbai, India | 17 Years |

Excel Magnetics Ahmedabad, India | 17 Years |

Sigma Instrumentation Ahmedabad, India | 15 Years |

Ecoman Vadodara, India | 15 Years |

Kp Industries Vadodara, India | 13 Years |

Popular Products